User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 1

Introducon (Ask a Queson)

This user guide describes the fabric architecture and its components available in the PolarFire

®

family. The FPGA

fabric is common to the PolarFire family, which consists of the following FPGA devices.

PolarFire

FPGAs

Microchip's PolarFire FPGAs are the fth-generation family of non-volatile FPGA devices, built on state-of-the-art 28 nm

non-volatile process technology. PolarFire FPGAs deliver the lowest power at mid-range densities. PolarFire FPGAs lower the

cost of mid-range FPGAs by integrating the industry’s lowest power FPGA fabric, lowest power 12.7 Gbps transceiver lane,

built-in low power dual PCI Express Gen2 (EP/RP), and, on select data security (S) devices, an integrated low-power crypto

co-processor.

PolarFire SoC

FPGAs

Microchip's PolarFire SoC FPGAs are the fth-generation family of non-volatile SoC FPGA devices, built on state-of-the-art

28 nm non-volatile process technology. The PolarFire SoC family oers industry's rst RISC-V based SoC FPGAs capable of

running Linux. It combines a powerful 64-bit 5x core RISC-V Microprocessor Subsystem (MSS), based on SiFive’s U54-MC

family, with the PolarFire FPGA fabric in a single device.

RT PolarFire

FPGAs

Microchip's RT PolarFire FPGAs combine our 60 years of space ight heritage with the industry’s lowest-power PolarFire

FPGA family to enable new capabilities for space and mission-critical applications. RT PolarFire FPGA family includes

RTPF500T, RTPF500TL, RTPF500TS, RTPF500TLS, RTPF500ZT, RTPF500ZTL, RTPF500ZTS, and RTPF500ZTLS devices.

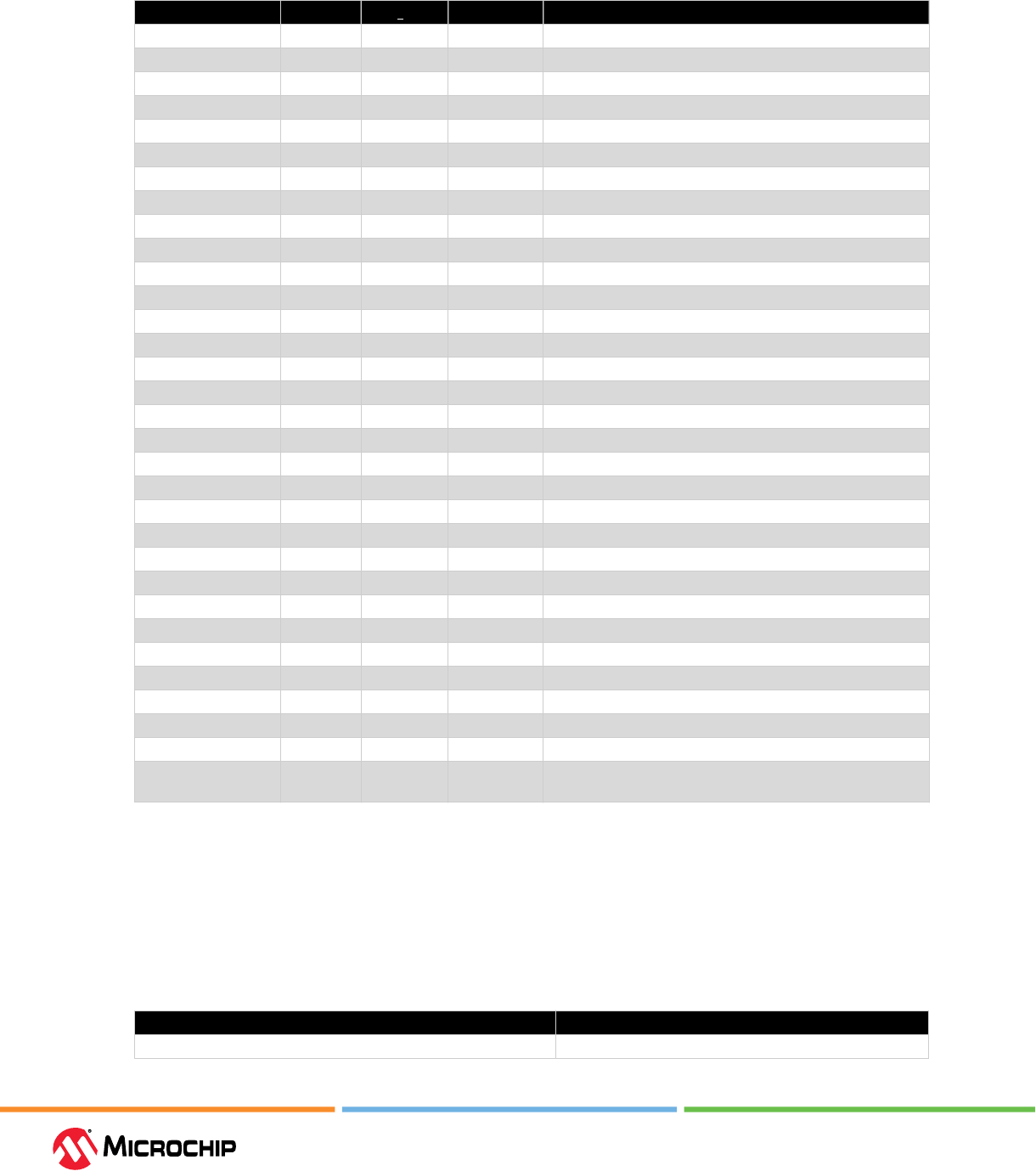

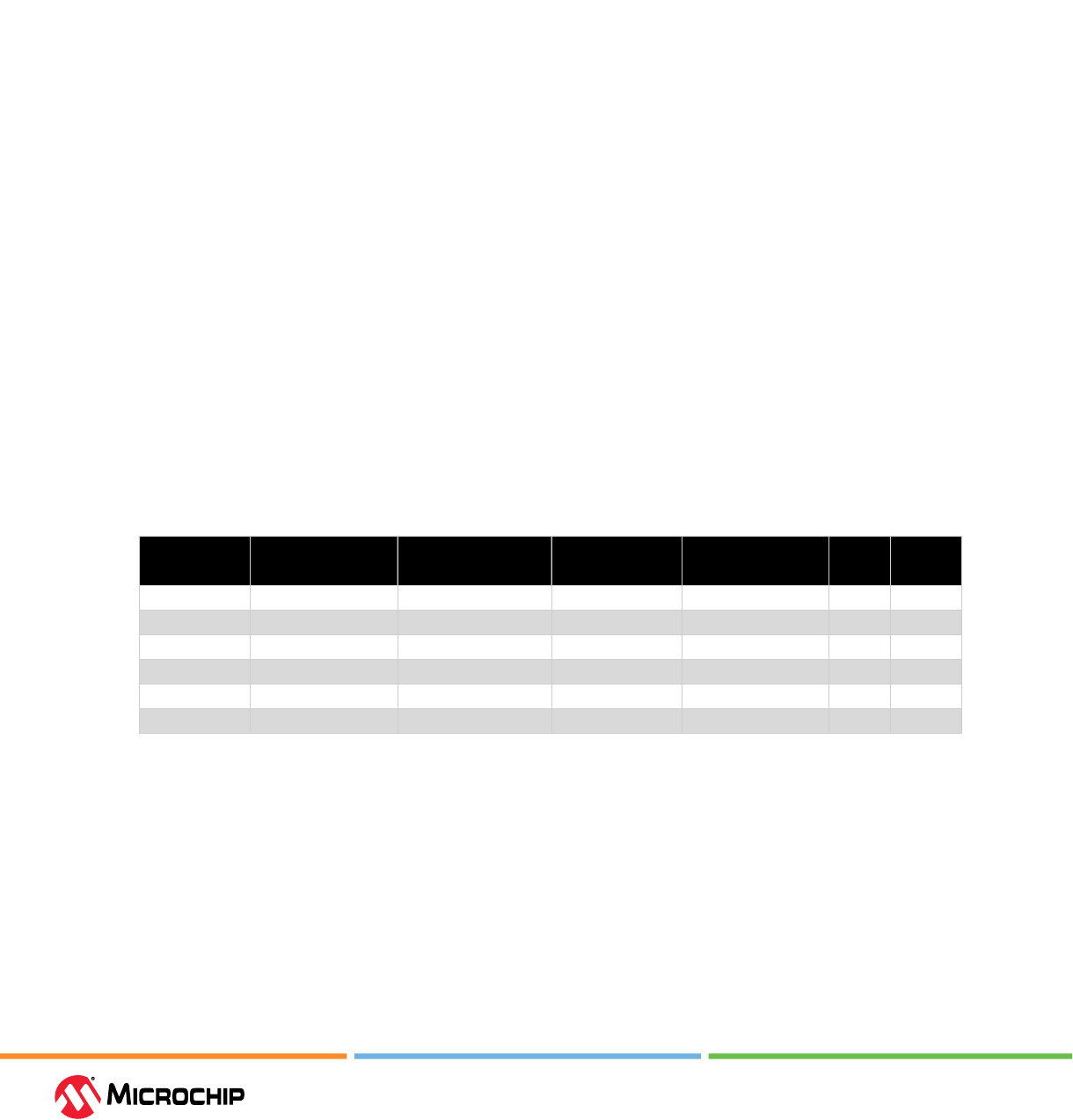

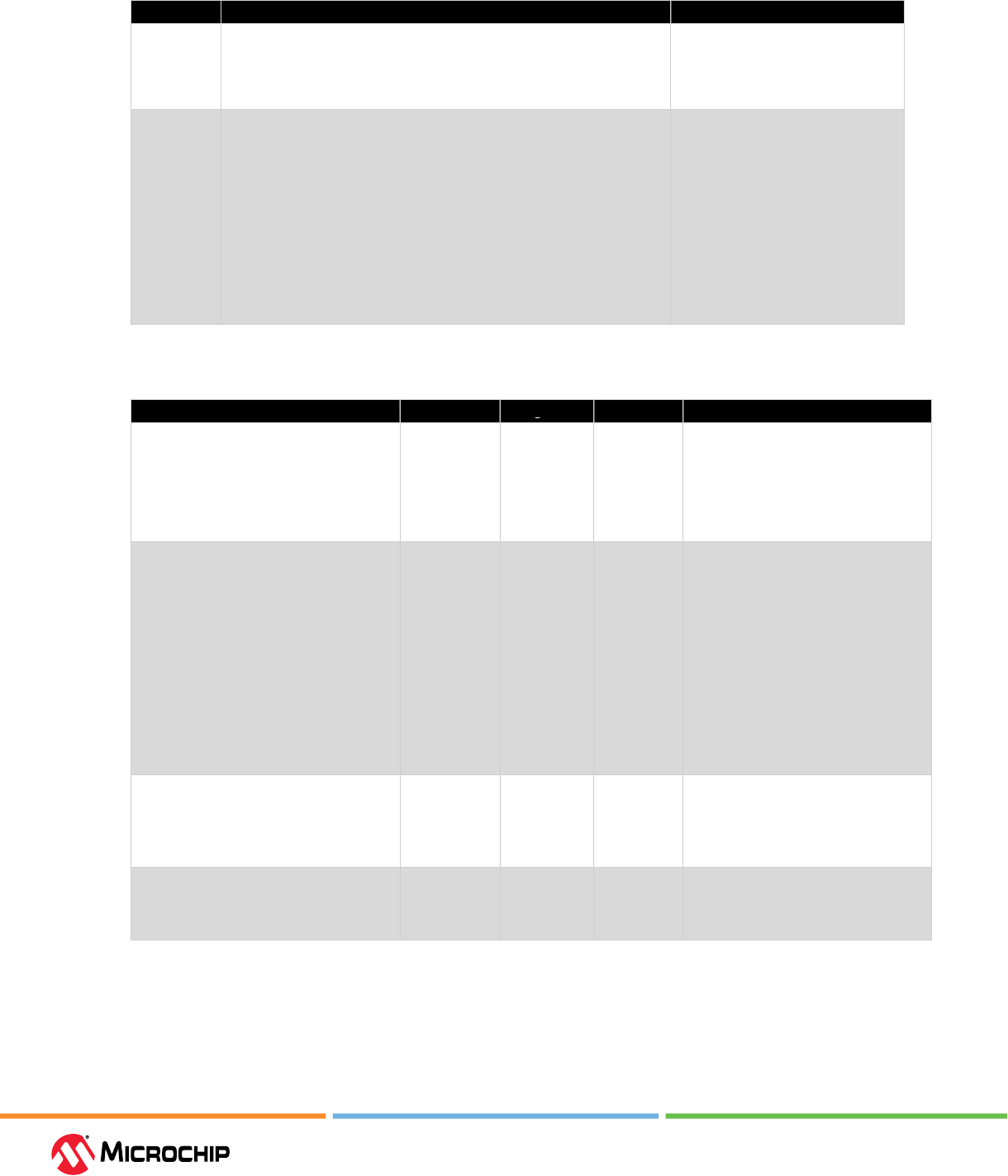

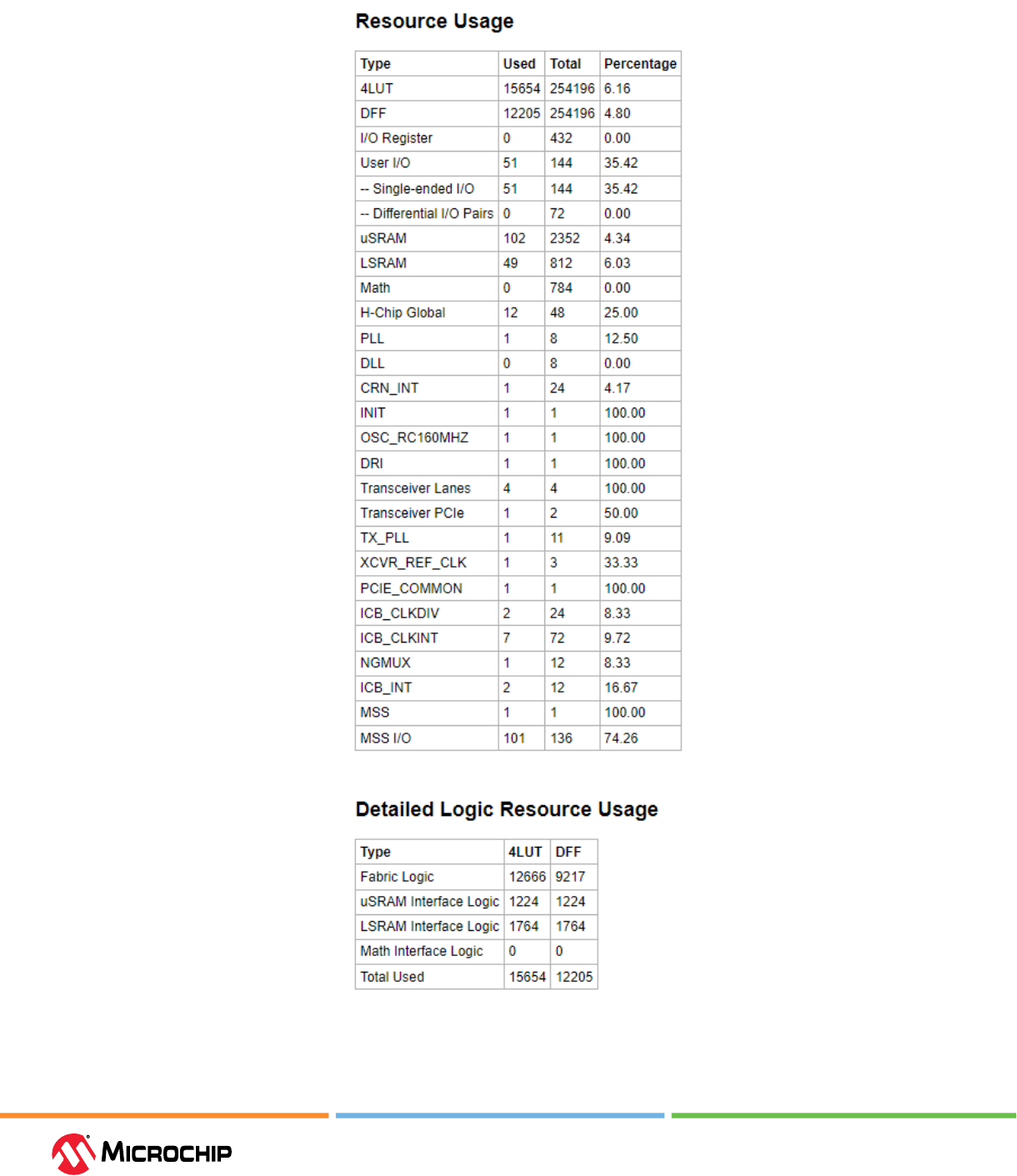

The following table summarizes fabric components available in the PolarFire family.

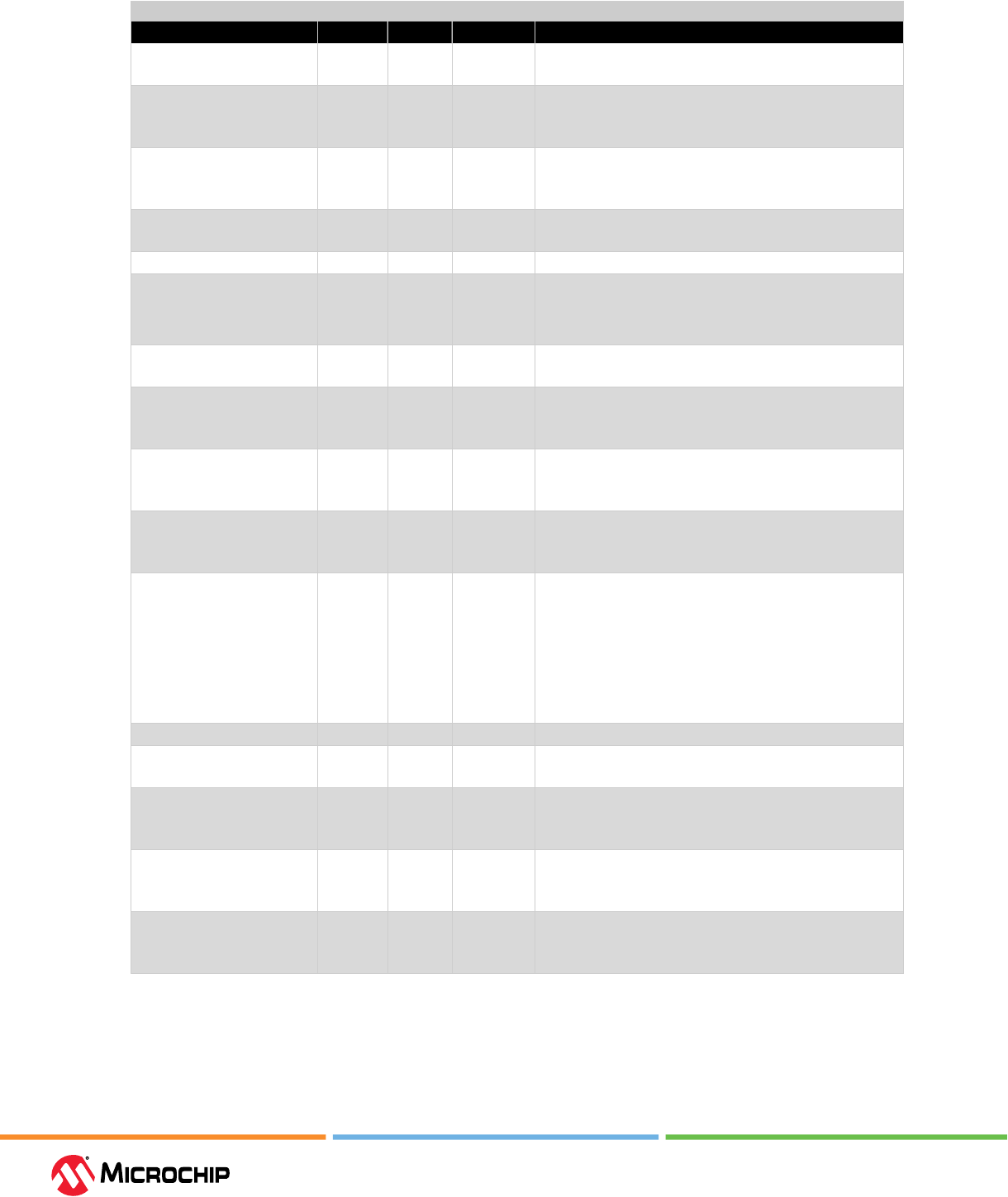

Table 1. Fabric Components

Component PolarFire

®

FPGA (MPF) PolarFire SoC FPGA

(MPFS)

RT PolarFire FPGA

(RTPF)

Logic Elements ✓ ✓ ✓

Embedded Memory Blocks large SRAM (LSRAM) ✓ ✓ ✓

microSRAM (μSRAM) ✓ ✓ ✓

microPROM (μPROM) ✓ ✓ ✓

secure non-volatile memory

(sNVM)

✓ ✓ ✓

eNVM — ✓ —

Math Blocks ✓ ✓ ✓

Microchip’s Libero

®

SoC Design Suite provides LSRAM, μSRAM, μPROM, and Math IP blocks. All these IP blocks

belong to the PolarFire family and can be seamlessly used in PolarFire SoC and RT PolarFire designs.

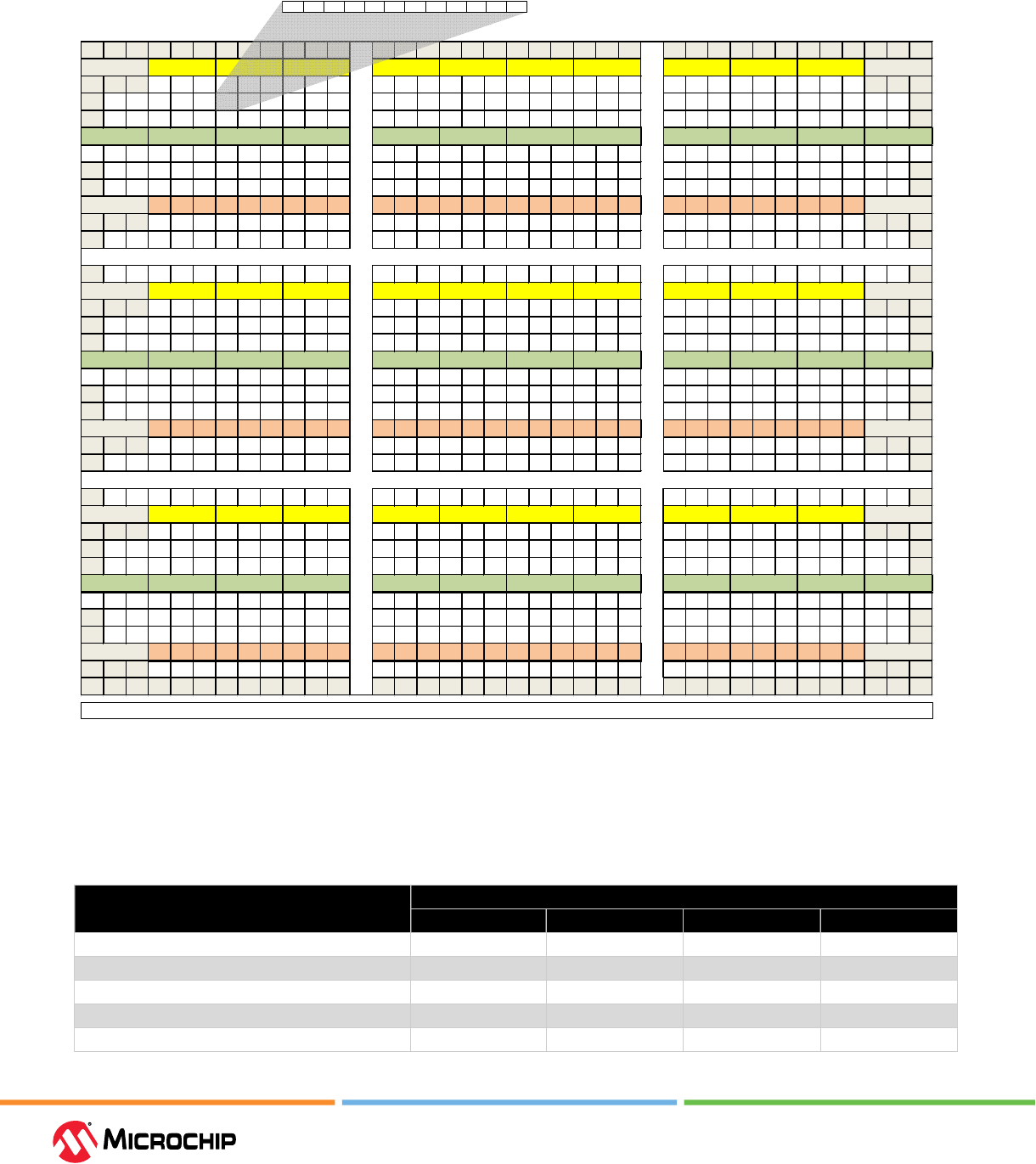

The fabric layout is shown in Figure 1. The FPGA logic resources are displayed as Logic Clusters (LC) and

Interface Logic (IL). Each LC and IL consists of 12 Logic Elements (LE). The embedded memory blocks and math

blocks are arranged in rows.

PolarFire Family Fabric User Guide

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 2

Figure 1. Fabric Layout

1 Logic Cluster = 12 Logic Elements

LE LE LE LE LE LE LE LE LE LE LE LE

M M M M M M M M M M

IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

R R R R R R R R R R R R

IL IL IL IL IL IL IL IL IL IL IL IL IL IL

IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ

IL IL IL IL IL IL IL IL IL IL IL IL IL IL

IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

M M M M M M M M M M

IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL

LC LC LC LC LC LC LC LC LC LC

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

R R R R R R R R R R R R

IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ

IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

M M M M M M M M M M

IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

R R R R R R R R R R R R

IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC LC

µ µ µ µ µ µ µ µ µ µ

µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ µ

IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL IL

LC – Logic cluster

IL – Interface logic

M – Math block

R – LSRAMs

µ – µSRAMs

µPROM

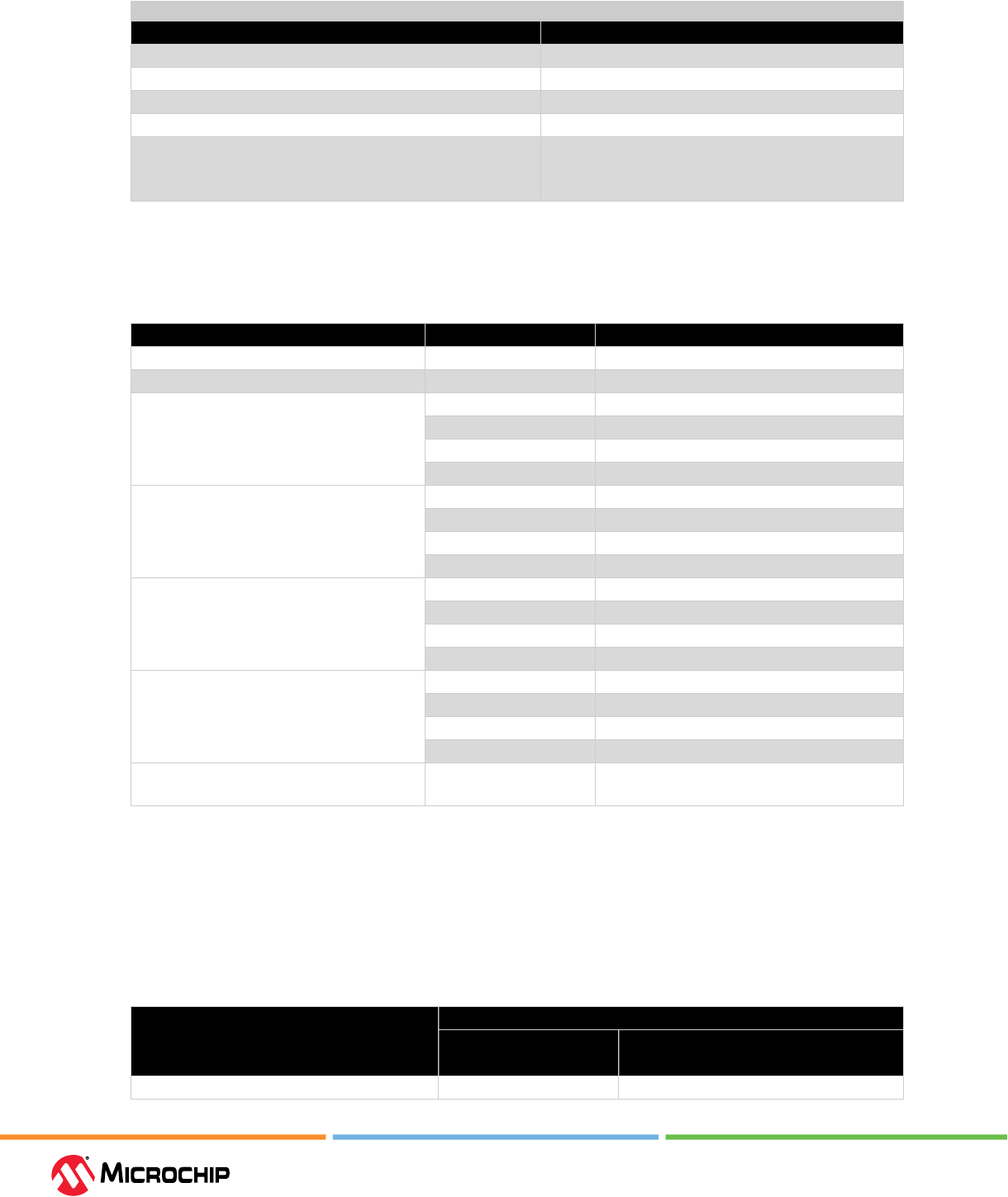

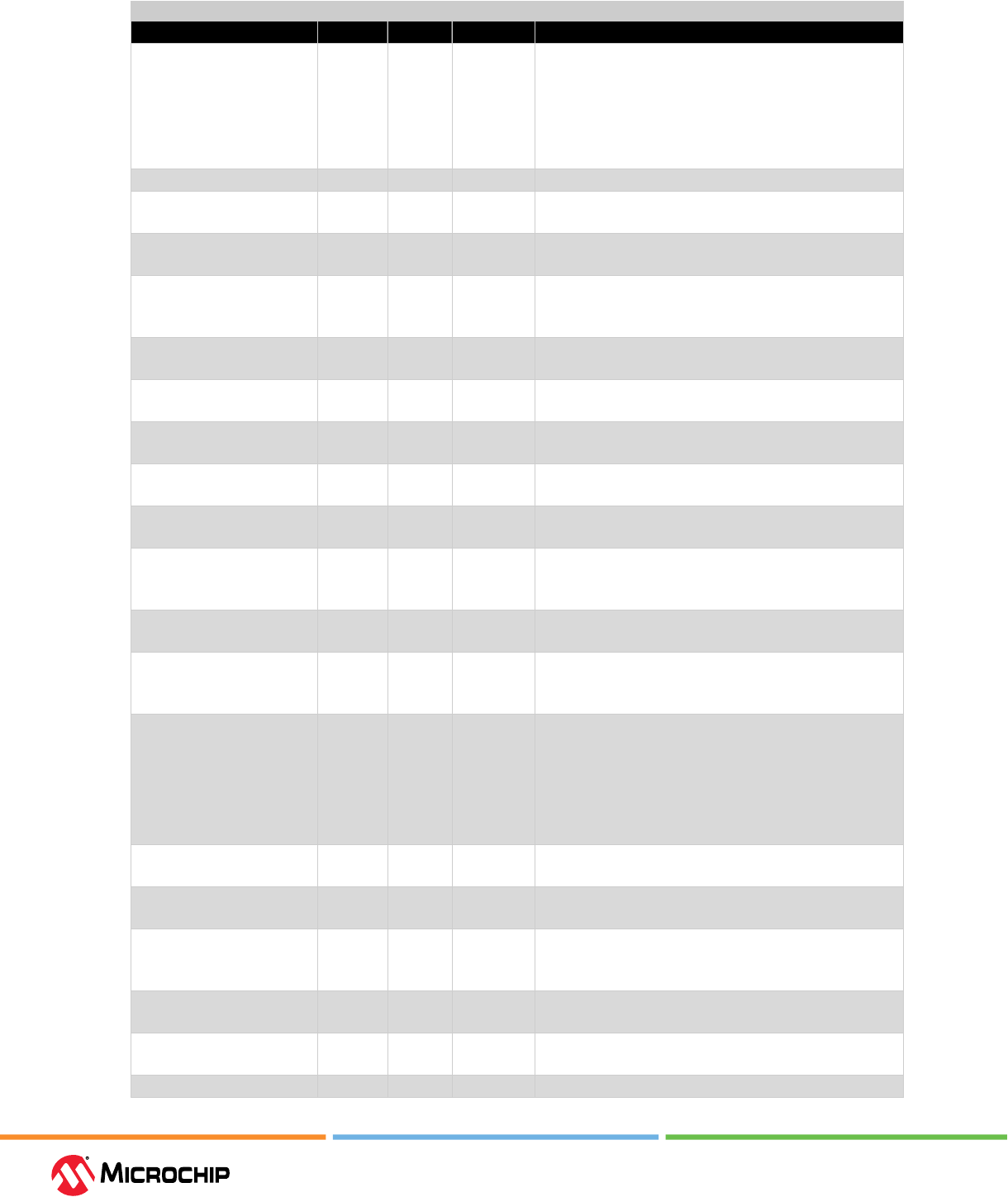

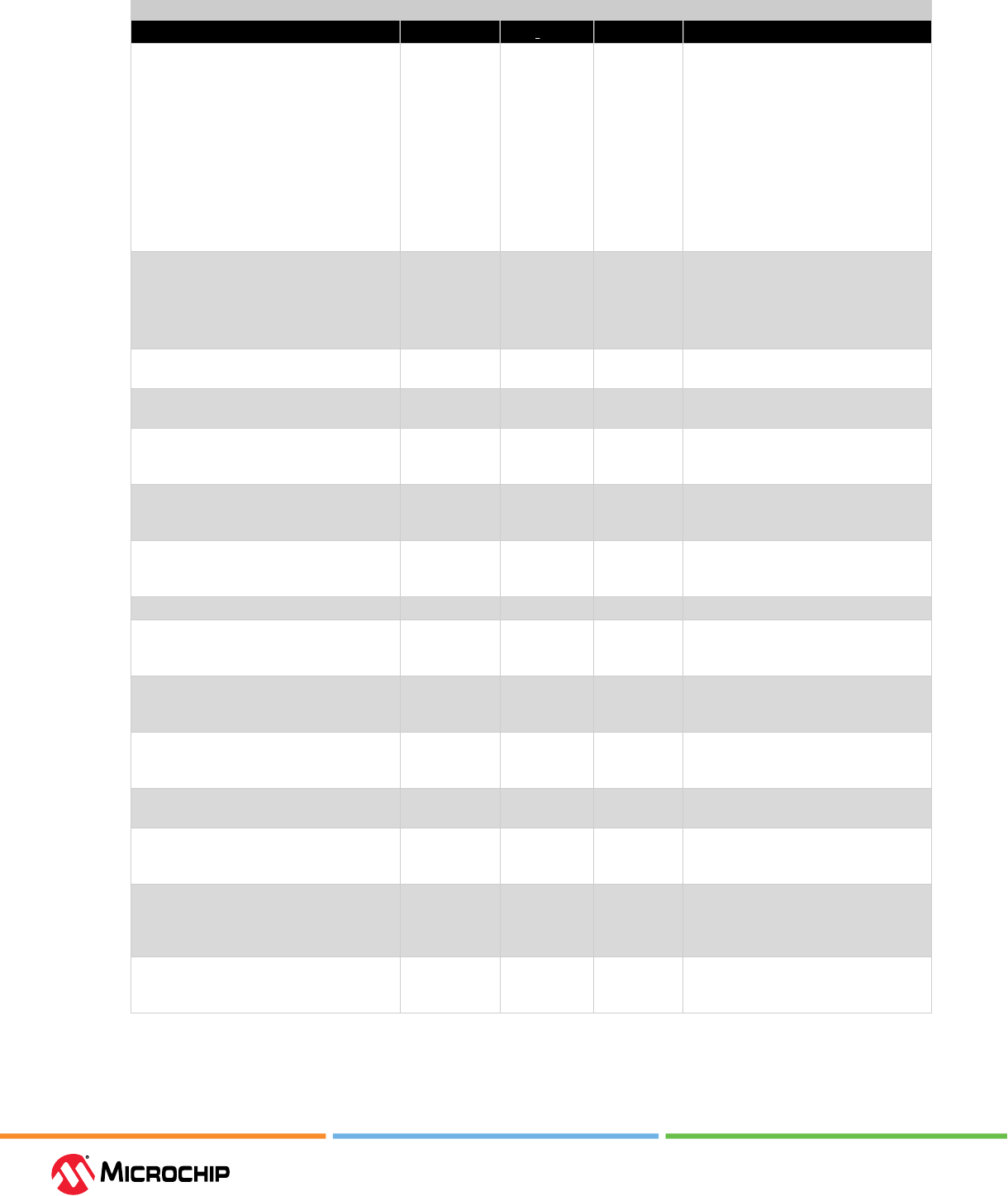

The following table lists the fabric resources available in the PolarFire devices.

Table 2. Fabric Resources in PolarFire Devices

Resources PolarFire

®

Devices

MPF100 MPF200 MPF300 MPF500

Logic elements (4LUT + DFF) 71,736 127,896 198,744 319,992

Interface logic 36,864 64,512 100,800 161,280

Total logic 108,600 192,408 299,544 481,272

LSRAM blocks (20 Kb each) 352 616 952 1,520

Total LSRAM bits (Mb) 6.87 12.03 18.59 29.69

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 3

...........continued

Resources PolarFire

®

Devices

MPF100 MPF200 MPF300 MPF500

μSRAM blocks (768 bits each) 1,008 1,764 2,772 4,440

Total μSRAM bits (Mb) 0.74 1.29 2.03 3.25

Total RAM (Mb) 7.6 13.32 20.62 32.94

Math blocks (18 × 18 MACC) 336 588 924 1,480

μPROM (Kb) 297 297 459 513

Note: 1 Kb = 1024 bits, 1 Mb = 1024 Kb.

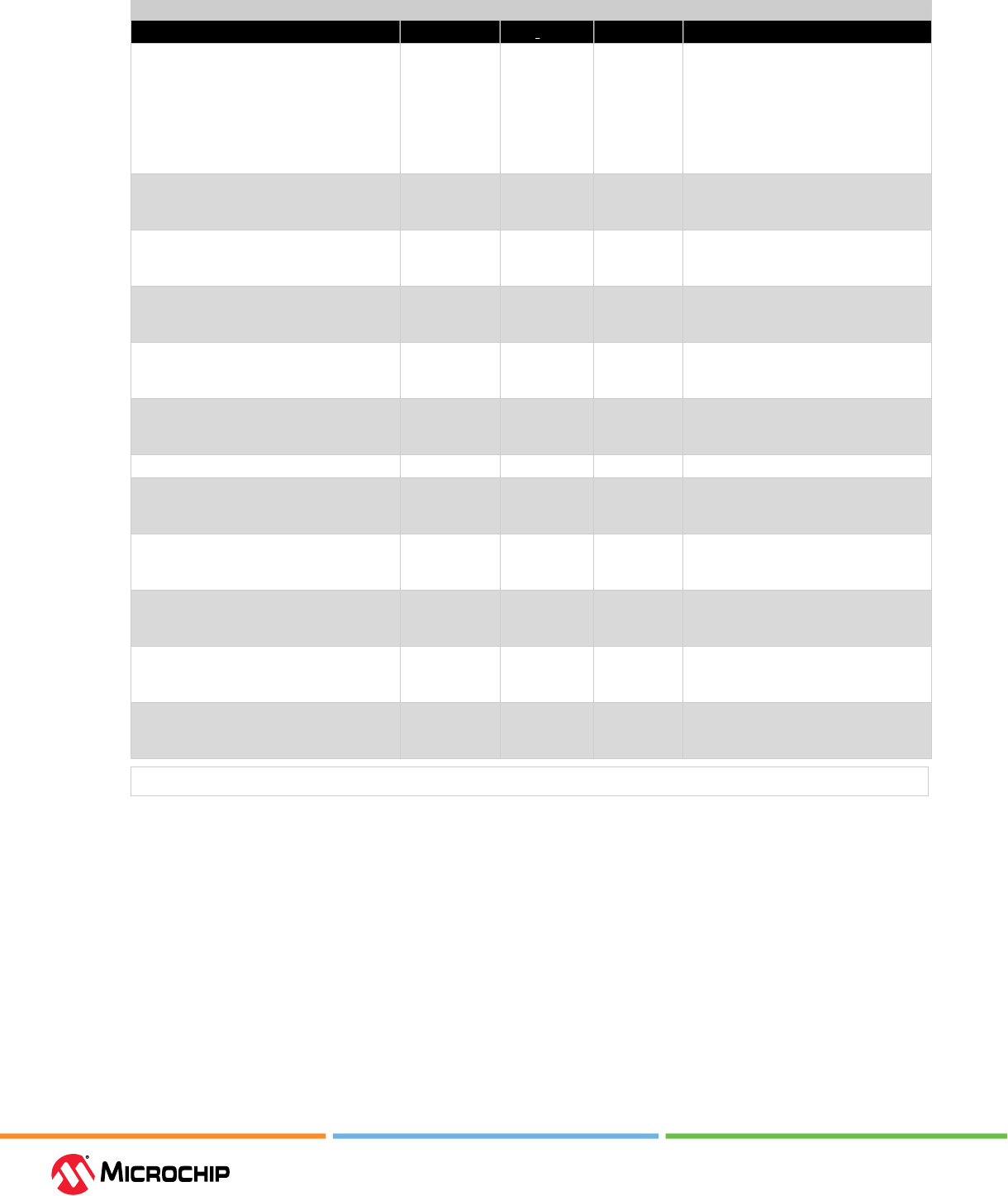

The following table lists the fabric resources available in the PolarFire SoC devices.

Table 3. Fabric Resources in PolarFire SoC Devices

Resources PolarFire

®

SoC Devices

MPFS025 MPFS095 MPFS160 MPFS250 MPFS460

Logic elements (4LUT + DFF) 23,000 93,000 1,61,000 2,54,000 4,61,000

Interface logic 7,920 32,112 54,576 85,680 1,54,800

LSRAM blocks (20 Kb each) 84 308 520 812 1,460

μSRAM blocks (768 bits each) 204 876 1,494 2,352 4,260

Total RAM (Mb) 1.8 6.7 11.3 17.6 31.6

Math blocks (18 × 18 MACC) 68 292 498 784 1,420

μPROM (Kb) 194 387 415 470 553

Note: 1 Kb = 1024 bits, 1 Mb = 1024 Kb.

The following table lists the fabric resources available in the RT PolarFire devices.

Table 4. Fabric Resources in RT PolarFire Devices

Resources RT PolarFire

®

Devices

Logic elements (4LUT + DFF) 319,992

Interface logic 161,280

Total logic 481,272

LSRAM blocks (20 Kb each) 1,520

Total LSRAM bits (Mb) 29.69

μSRAM blocks (768 bits each) 4,440

Total μSRAM bits (Mb) 3.25

Total RAM (Mb) 32.94

Math blocks (18 × 18 MACC) 1,480

μPROM (Kb) 513

Note: 1 Kb = 1024 bits, 1 Mb = 1024 Kb.

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 4

Table of Contents

Introduction...........................................................................................................................................................................1

1. Logic Element and Routing.......................................................................................................................................... 5

1.1. Logic Element..................................................................................................................................................... 5

1.2. Interface Logic.................................................................................................................................................... 5

1.3. Logic Cluster....................................................................................................................................................... 8

1.4. Routing Architecture..........................................................................................................................................8

1.5. Fabric X-Y Coordinates...................................................................................................................................... 8

2. Embedded Memory Blocks........................................................................................................................................ 10

2.1. LSRAM............................................................................................................................................................... 11

2.2. μSRAM............................................................................................................................................................... 36

2.3. μPROM.............................................................................................................................................................. 45

2.4. sNVM................................................................................................................................................................. 59

2.5. eNVM (PolarFire SoC Only)............................................................................................................................. 60

3. Math Blocks..................................................................................................................................................................61

3.1. Features............................................................................................................................................................ 61

3.2. Math Block Resources..................................................................................................................................... 61

3.3. Functional Description.................................................................................................................................... 61

3.4. Cascading Math Blocks....................................................................................................................................66

3.5. Operational Modes..........................................................................................................................................68

3.6. Implementation............................................................................................................................................... 71

4. Appendix: Supported Memory File Formats for LSRAM and μSRAM....................................................................79

4.1. Write Port Width Alignment............................................................................................................................81

5. Appendix: Macro Conguration................................................................................................................................ 88

5.1. LSRAM Macro................................................................................................................................................... 88

5.2. μSRAM Macro................................................................................................................................................... 95

5.3. Math Block Macro............................................................................................................................................ 97

5.4. Libero SoC Compile Report.......................................................................................................................... 109

6. References................................................................................................................................................................. 113

7. Revision History.........................................................................................................................................................114

Microchip FPGA Support..................................................................................................................................................117

Microchip Information..................................................................................................................................................... 117

The Microchip Website............................................................................................................................................. 117

Product Change Notication Service...................................................................................................................... 117

Customer Support.................................................................................................................................................... 117

Microchip Devices Code Protection Feature..........................................................................................................117

Legal Notice............................................................................................................................................................... 118

Trademarks................................................................................................................................................................ 118

Quality Management System.................................................................................................................................. 119

Worldwide Sales and Service...................................................................................................................................120

Logic Element and Roung

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 5

1. Logic Element and Roung (Ask a Queson)

The fabric includes an array of logic elements grouped in clusters connected by hierarchical

routing structures. These clusters are arranged in rows and are used to implement sequential and

combinational logic. See Figure 1-7 and Figure 1-8 for PolarFire and PolarFire SoC fabric coordinates

respectively.

1.1 Logic Element (Ask a Queson)

The logic element consists of a 4-input Lookup Table (LUT) with a carry chain and D-type ip-

op, as shown in Figure 1-1. The logic element is fracturable, which means that the LUT can be

independently used without ip-op, or ip-op can be used without LUT.

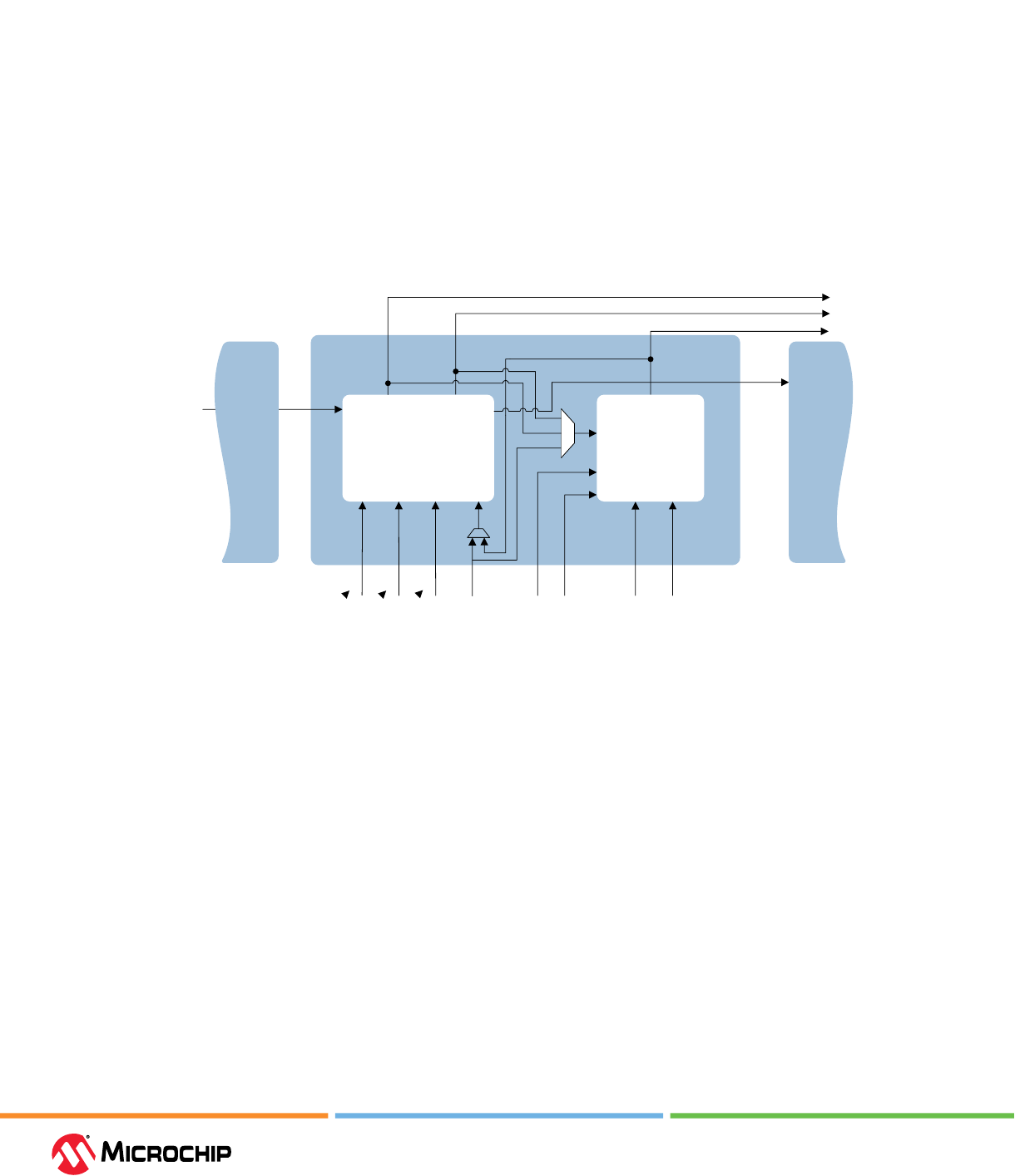

Figure 1-1. Funconal Block Diagram of Logic Element

Logic Element

SUM (S)

Y

4-LUT

with Carry Chain

D1

data

Cout

Cout

Cin

Q

EN CLK SLn ALn

Cin

S

Y

Cout

D

A B C

C

BA

Logic Element

Cin

Logic Element

ALn

Flip-Flop

D

EN

CLK

SLn

Q

The 4-input LUT with carry chain can be

congured to implement any 4-input combinational logical

function or arithmetic function. The 4-input LUT generates the output (Y) depending on the four

inputs—A, B, C, and D. The carry chain is implemented using a 3-bit carry-look-ahead circuit. This

circuit is connected between various logic elements by carry chain input (Cin) signal and carry chain

output (Cout) signal. When the LUT is used to implement arithmetic functions, the carry chain input

(Cin) is used with LUT output to generate the Sum (S) output. However, for non-arithmetic functions,

the sum (S) output can still be used as an output along with the other output (Y).

The D-type ip-op can be used as a register or latch. The data input (D) of the D-type ip-op

can be sourced from one of three inputs: the direct input (D1), the combinational output (Y) of the

LUT, or the sum output (S) of the LUT (Figure 1-1). The ALn and SLn are asynchronous load and

synchronous load active-low signals that can be congured as reset signal. The ip-op output (Q)

can be an output of the logic element or one of the data inputs to the 4-input LUT (inside the same

logic element).

1.2 Interface Logic (Ask a Queson)

The embedded hard IP blocks (LSRAM, μSRAM, and Math blocks) are connected to the fabric through

Interface Logic (ILs).

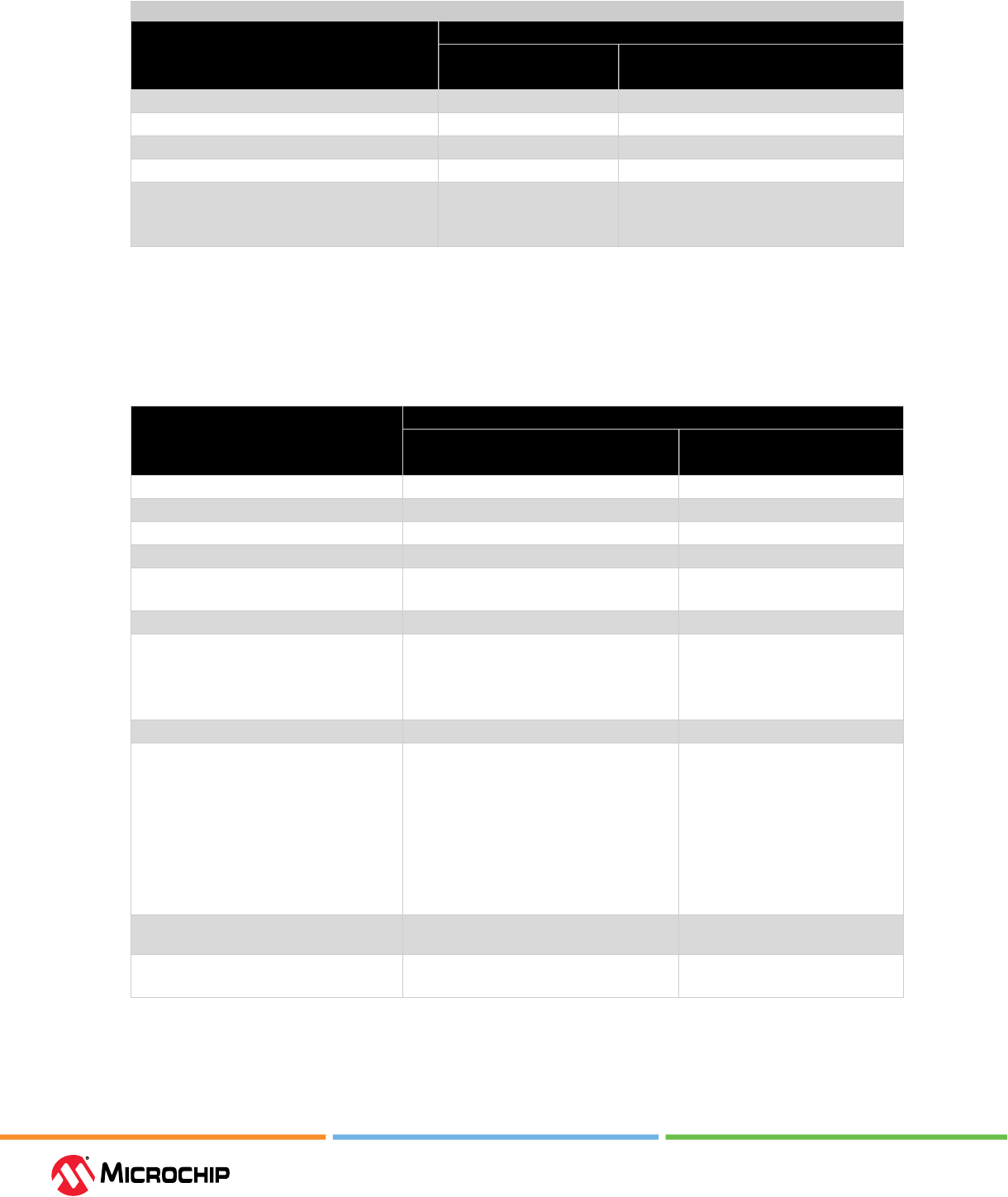

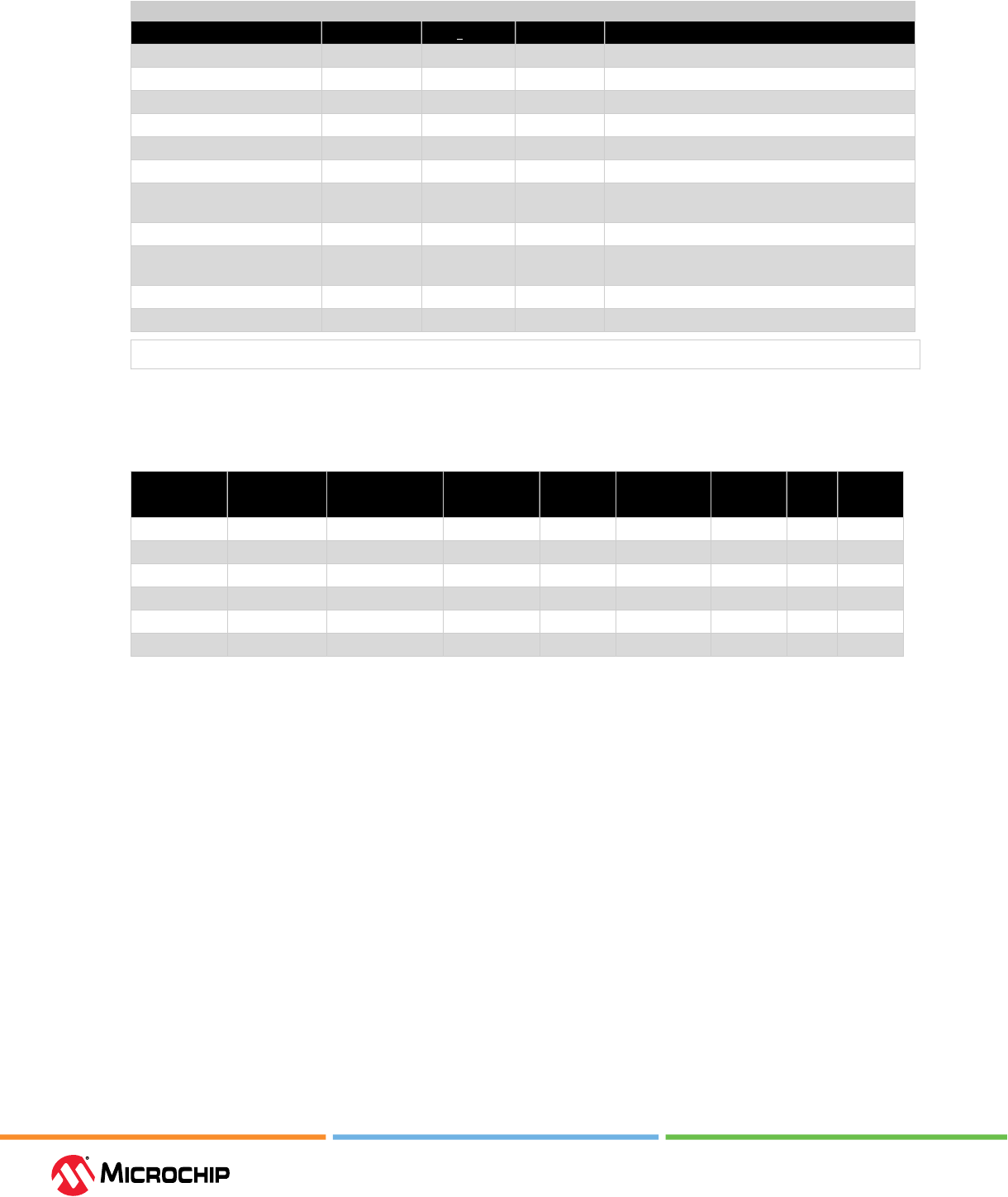

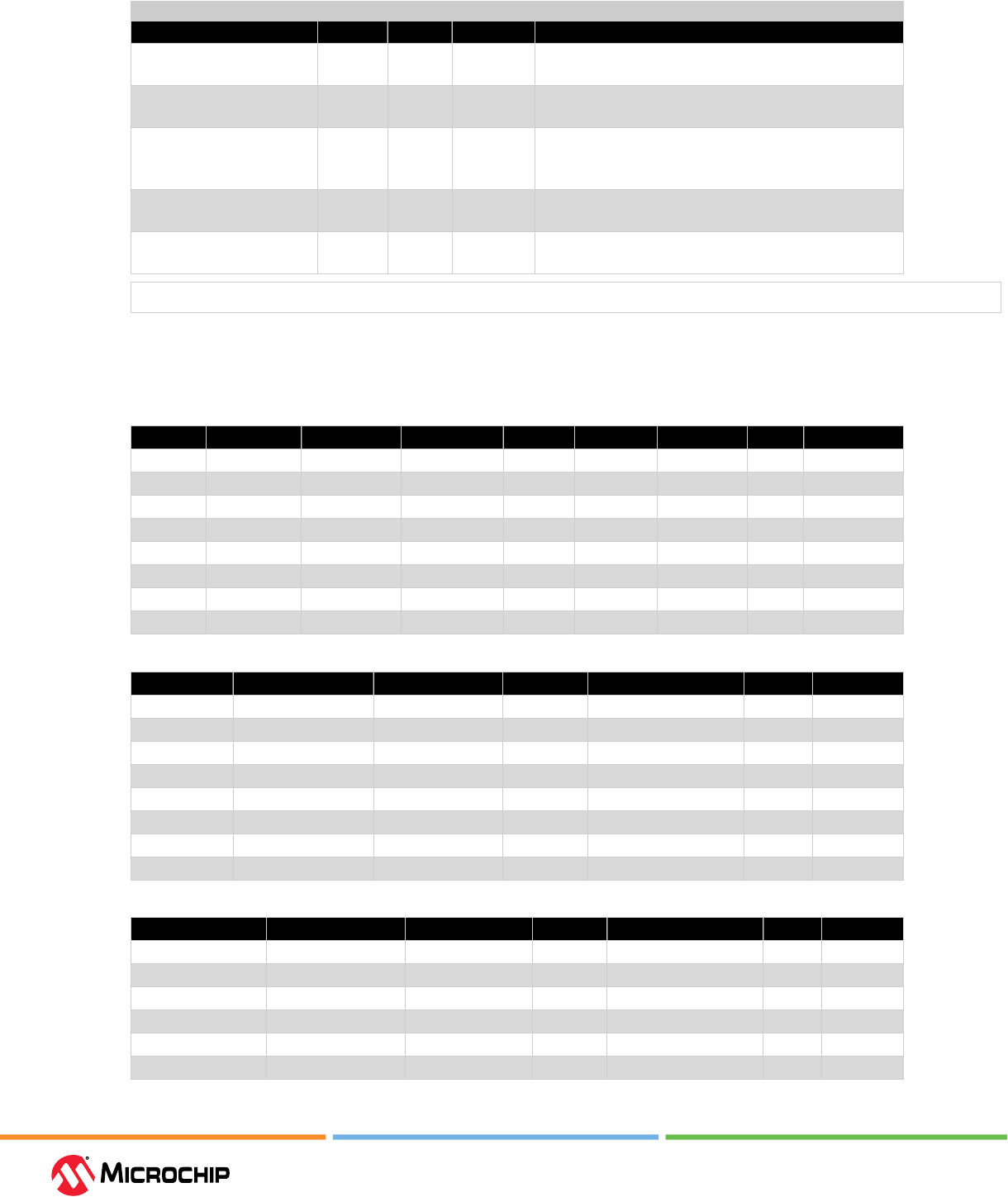

The following table lists the total number of ILs associated with each memory block in the PolarFire

devices.

Logic Element and Roung

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 6

Table 1-1. ILs for Embedded Hard IP Blocks (PolarFire Devices)

Resources MPF100 MPF200 MPF300 MPF500

No. of

Blocks

No. of ILs No. of

Blocks

No. of ILs No. of

Blocks

No. of ILs No. of

Blocks

No. of ILs

LSRAM 352 12,672 616 22,176 952 34,272 1,520 54,720

μSRAM 1008 12,096 1,764 21,168 2,772 33,264 4,440 53,280

Math block 336 12,096 588 21,168 924 33,264 1,480 53,280

Total interface logic — 36,864 — 64,512 — 100,800 — 161,280

The following table lists the total number of ILs associated with each memory block in the PolarFire

SoC devices.

Table 1-2. ILs for Embedded Hard IP Blocks (PolarFire SoC Devices)

Resources MPFS025 MPFS095 MPFS160 MPFS250 MPFS460

No. of

Blocks

No. of

ILs

No. of

Blocks

No. of

ILs

No. of

Blocks

No. of

ILs

No. of

Blocks

No. of

ILs

No. of

Blocks

No. of

ILs

LSRAM 84 3024 308 11088 520 18720 812 29232 1460 52560

μSRAM 204 2448 876 10512 1494 17928 2352 28224 4260 51120

Math block 68 2448 292 10512 498 17928 784 28224 1420 51120

Total interface

logic

— 7920 — 32112 — 54576 — 85680 — 154800

The following table lists the total number of ILs associated with each memory block in the RT

PolarFire devices.

Table 1-3. ILs for Embedded Hard IP Blocks (RT PolarFire Devices)

Resources RT PolarFire

®

Devices

No. of Blocks No. of ILs

LSRAM 1,520 54,720

μSRAM 4,440 53,280

Math block 1,480 53,280

Total interface logic — 161,280

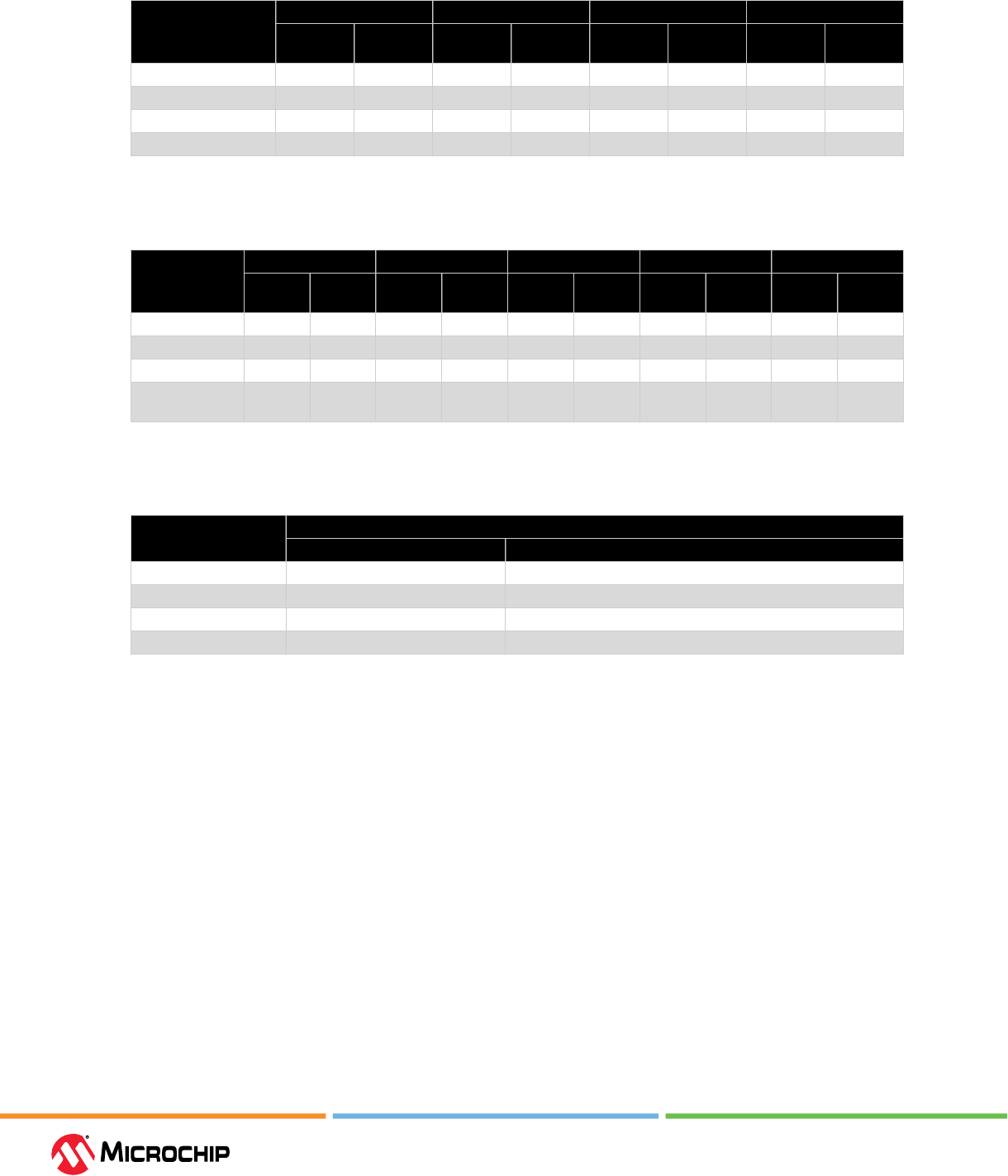

The ILs are structurally similar to LEs with a 4-input LUT and D-type ip-op, but without a dedicated

carry chain, as shown in the following gure.

Logic Element and Roung

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 7

Figure 1-2. Funconal Block Diagram of Interface Logic

Flip-Flop4-LUT

Interface Logic

D1

ALn

data

D

EN

CLK

SLn

Q

CBA EN CLK SLn ALn

A B C

D

Y

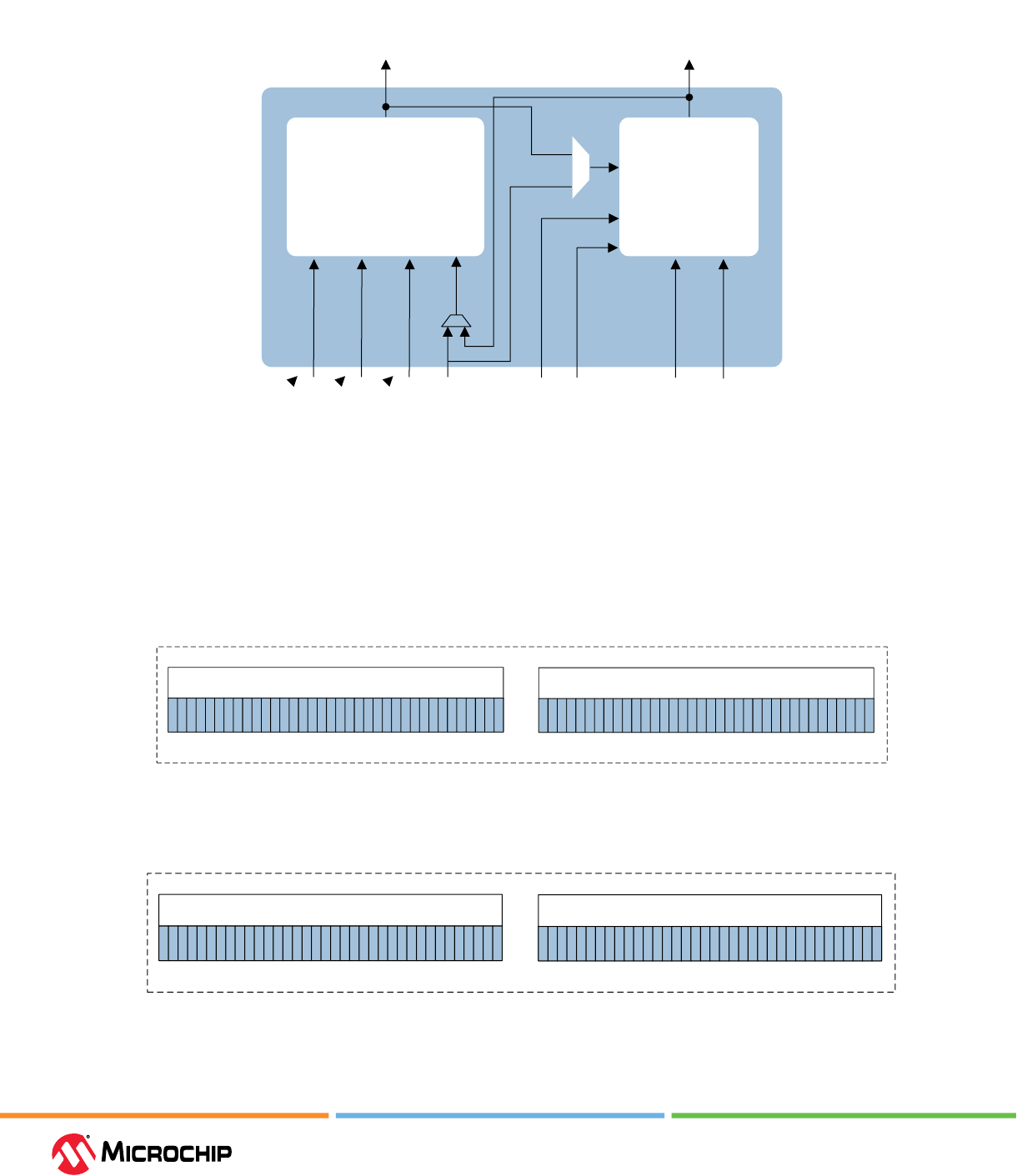

Each LSRAM and Math block is associated with 36 ILs, and each μSRAM is associated with 12 ILs. For

more information, see Figure 1-3, Figure 1-4, and Figure 1-5.

If an embedded hard IP block is used in a design, the associated ILs connect the ports of the

embedded hard IP blocks to the fabric routing. Any IL that is not utilized by an embedded hard IP

block is automatically available for user logic.

Figure 1-3. LSRAM Interfacing with ILs in a Row

Row

...

36 Interface Logic 36 Interface Logic

LSRAM

LSRAM

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

Figure 1-4. Math Block Interfacing with ILs in a Row

Row

...

36 Interface Logic 36 Interface Logic

Math Block

Math Block

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

Logic Element and Roung

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 8

Figure 1-5. μSRAMs Interfacing with ILs in a Row

Row

...

12 Interface Logic 12 Interface Logic

µSRAM µSRAM

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

I

L

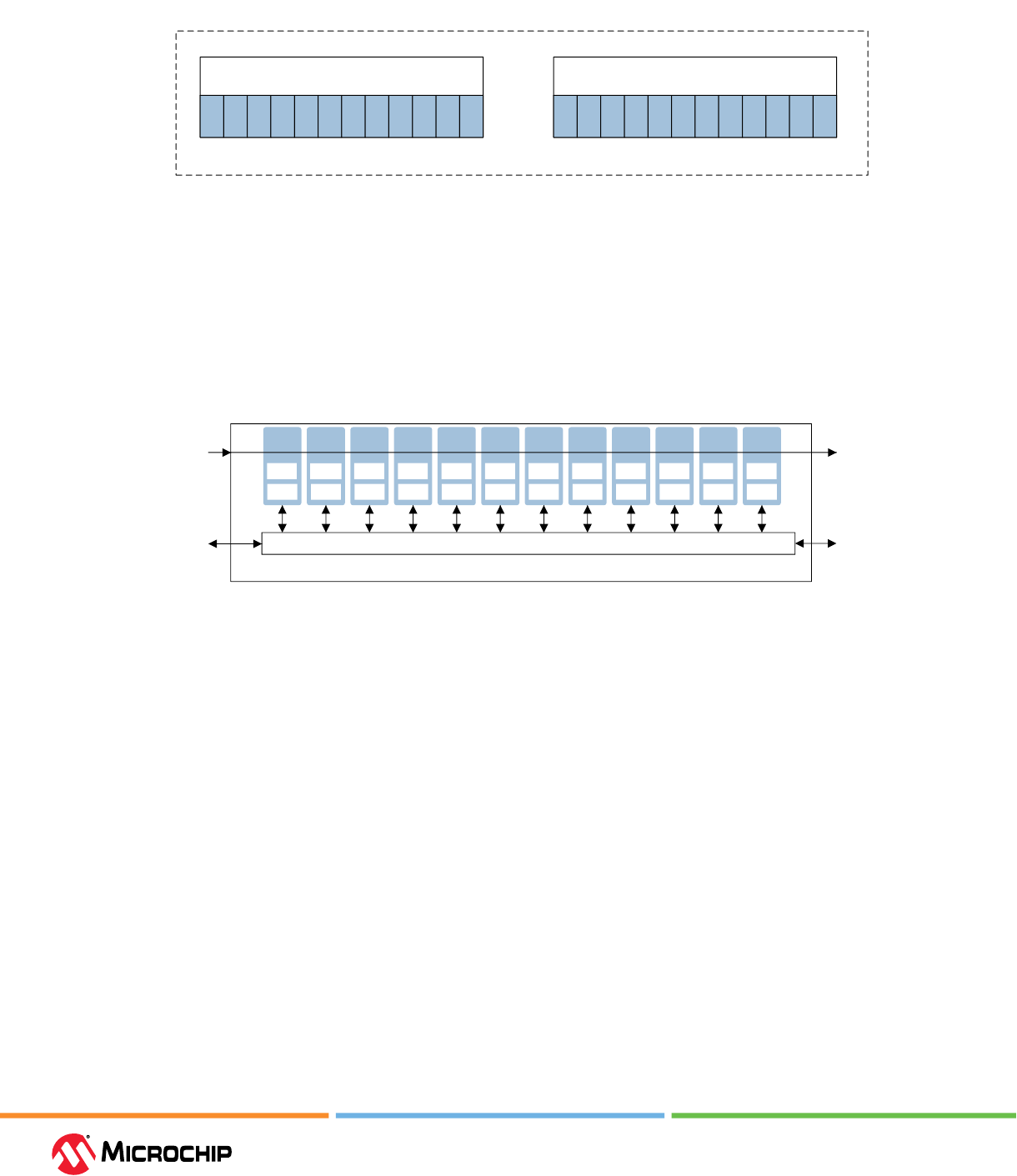

1.3 Logic Cluster (Ask a Queson)

The logic elements in the FPGA fabric are organized in clusters. A logic cluster is a group of 12 LEs.

Each logic cluster is connected by a routing interface that connects to its associated LEs and the

adjacent routing interfaces.

The following gure shows the logic cluster with its routing interface.

Figure 1-6. Logic Cluster

Routing Interface

Adjacent

Routing

Interface

Adjacent

Routing

Interface

FF FF FF FF FF FF FF FF FF FF FF FF

LE

LE

LE

LE

LE

LE

LE

LE

LE

LE

LE

LE

Carry In

Carry Out

Logic Cluster

LUT

LUT

LUT

LUT

LUT

LUT

LUT

LUT

LUT

LUT

LUT

LUT

1.4 Roung Architecture (Ask a Queson)

The PolarFire family supports two types of routings—intra-cluster routing and inter-cluster routing.

The intra-cluster routing connects the LEs within a cluster, and inter-cluster routing connects LEs

between multiple clusters. The intra-cluster routing has lower propagation delay compared to inter-

cluster routing. When connecting the adjacent clusters, inter-cluster routing also has additional

short routing connections for faster routing.

1.5 Fabric X-Y Coordinates (Ask a Queson)

Each 4-input LUT, D-type ip-op, carry chain, LSRAM, μSRAM, and Math block has individual X-Y

coordinates. For manual placement of these blocks, it is possible to set region constraints using

these coordinates. The coordinates are measured from the lower left (0, 0) to the top right corner (X,

Y); where X, Y values vary for each device. For more details, see SmartTime User Guide, I/O Editor User

Guide, and ChipPlanner User Guide on Libero SoC Design Resources page.

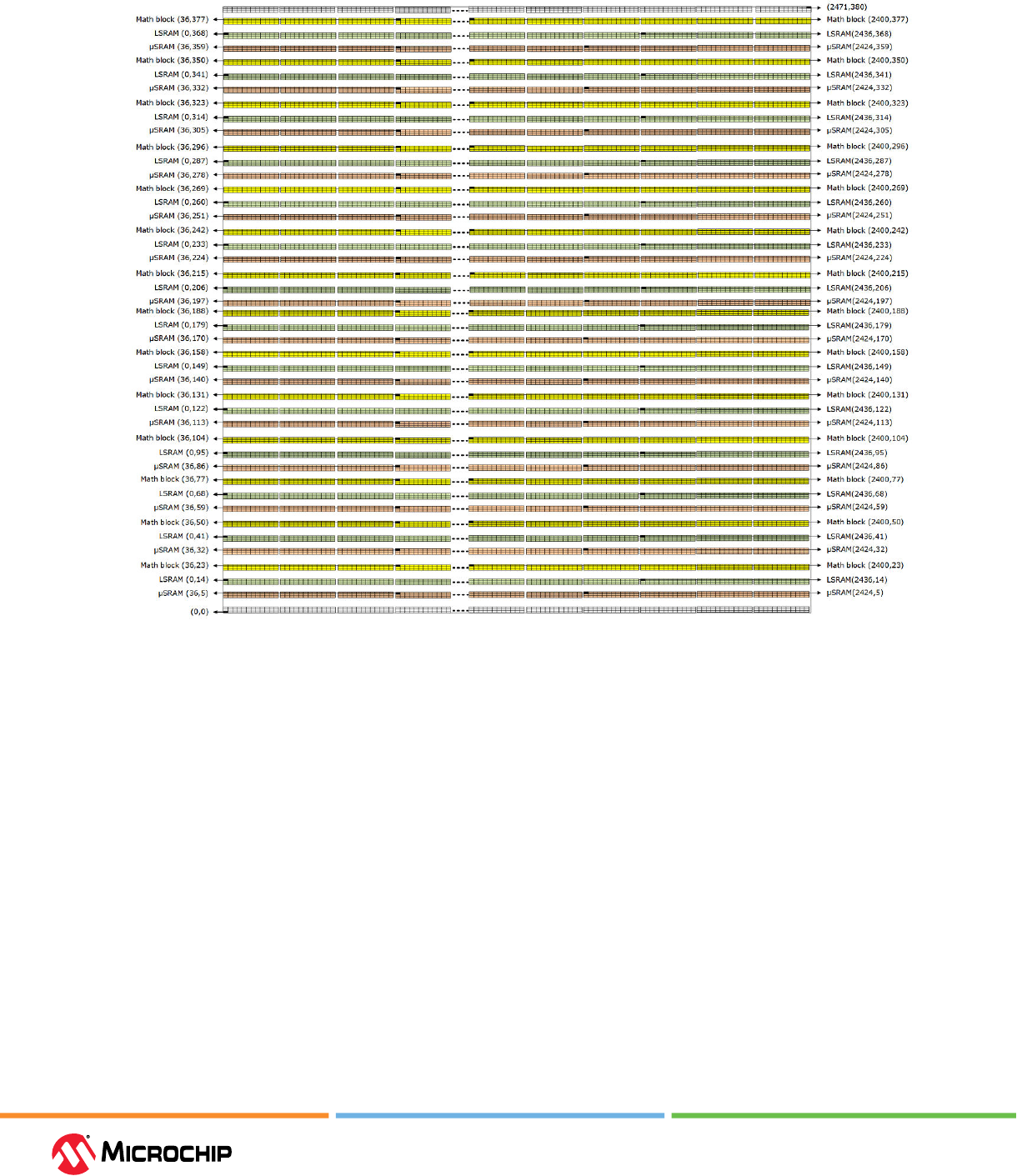

The following gure shows the available X-Y coordinates of LSRAM, μSRAM, and Math block for

placement constraints for the PolarFire MPF300 device.

Logic Element and Roung

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 9

Figure 1-7. MPF300 Fabric X-Y Coordinates

Figure 1-8 shows the available X-Y coordinates of LSRAM, μSRAM, and Math block for placement

constraints for the PolarFire SoC MPFS250 device.

Figure 1-8. MPFS250 Fabric X-Y Coordinates

To be updated.

The following gure shows the available X-Y coordinates of LSRAM, μSRAM, and Math block for

placement constraints for the RT PolarFire RTPF500 device.

Figure 1-9. RTPF500 Fabric X-Y Coordinates

To be updated.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 10

2. Embedded Memory Blocks (Ask a Queson)

The PolarFire family has the following memory blocks:

• LSRAM—The embedded large SRAM blocks are 20Kbits each with 20-bit width and a depth of

1024 locations. The LSRAMs can be congured as either dual port or two port memories. The

number of LSRAMs available in a device varies as shown in Table 2 and Table 3. The LSRAMs

support ECC when congured in 33-bit data width in two-port mode. LSRAMs can be congured

in various modes as shown in Table 2-1. LSRAMs can be initialized with user data during power-

up.

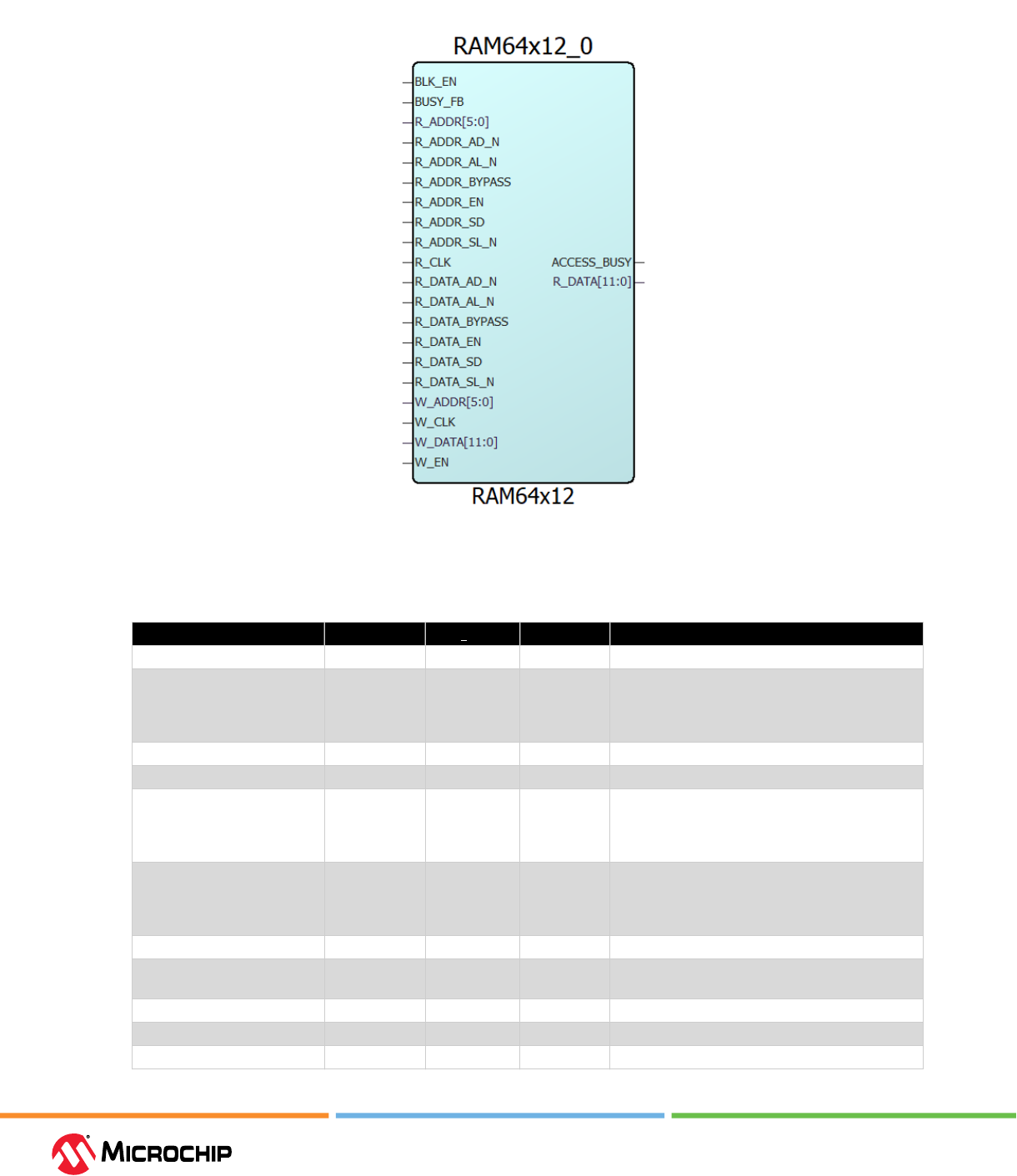

• μSRAM—The embedded 768-bit SRAM blocks (RAM64x12) are arranged in multiple rows within

the fabric and can be accessed through the fabric routing architecture. The number of available

μSRAM blocks depends on the specic device, as shown in Table 2 and Table 3. μSRAMs can be

initialized during power-up.

• μPROM—The embedded non-volatile PROM is arranged in a single row at the bottom of the

fabric and is read only through the fabric interface. μPROM is programmed with the FPGA

bitstream during fabric programming and it cannot be programmed independently. μPROM is

used to store the initialization data for LSRAM and μSRAM and other user data.

• sNVM—Each PolarFire FPGA has 56 KB of Secure Non-volatile Memory (sNVM). The sNVM can

be used to initialize LSRAM and μSRAMs with secure data. sNVM can be accessed through the

system services.

Along with the above memory blocks, the PolarFire SoC family includes the following memory block:

• eNVM (PolarFire SoC Only)—The 128 KB of eNVM is located in the MSS. eNVM is used to store the

rst stage bootloader program for booting the E51 monitor core. eNVM is programmed with the

device bitstream during the device programming, it cannot be programmed independently.

The following table lists the features of the memory blocks of the PolarFire family.

Table 2-1. LSRAM, μSRAM, μPROM, and sNVM Features

Feature LSRAM

(PolarFire, PolarFire

SoC, and RT PolarFire)

μSRAM (PolarFire,

PolarFire SoC, and

RT PolarFire)

μPROM

(PolarFire,

PolarFire SoC,

and RT PolarFire)

sNVM (PolarFire,

PolarFire SoC,

and RT PolarFire)

eNVM (Only

PolarFire SoC)

Memory size 20,480 bits/block 768-bit/block See Table 2 and

Table 3

56 Kbytes 128 Kbytes

Memory

Conguration

Options

16K × 1, 8K × 2, 4K × 5,

2K × 10, 1K × 20, 512

× 40

1

, and 512 × 33

1

(with ECC)

64 × 12 Up to 64K × 9 Not Applicable Not Applicable

Number of ports 2 read ports, 2 write

ports

1 read port, 1 write

port

1 read port Not Applicable Not Applicable

Memory modes True dual-port and

two-port

Two-port Single-port Not Applicable Not Applicable

Read operation Synchronous Synchronous/

Asynchronous

Asynchronous Through system

service calls

Asynchronous

Write operation Simple write, feed-

through write, and

read-before-write

Simple write Only during

device

programming

During device

programming

and System

Service calls

During device

programming

ECC Available for two-port

mode (512 × 33) only

Not available Not Applicable Not Applicable Not Applicable

Note:

1. ×40 and ×33 are only available in two-port mode.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 11

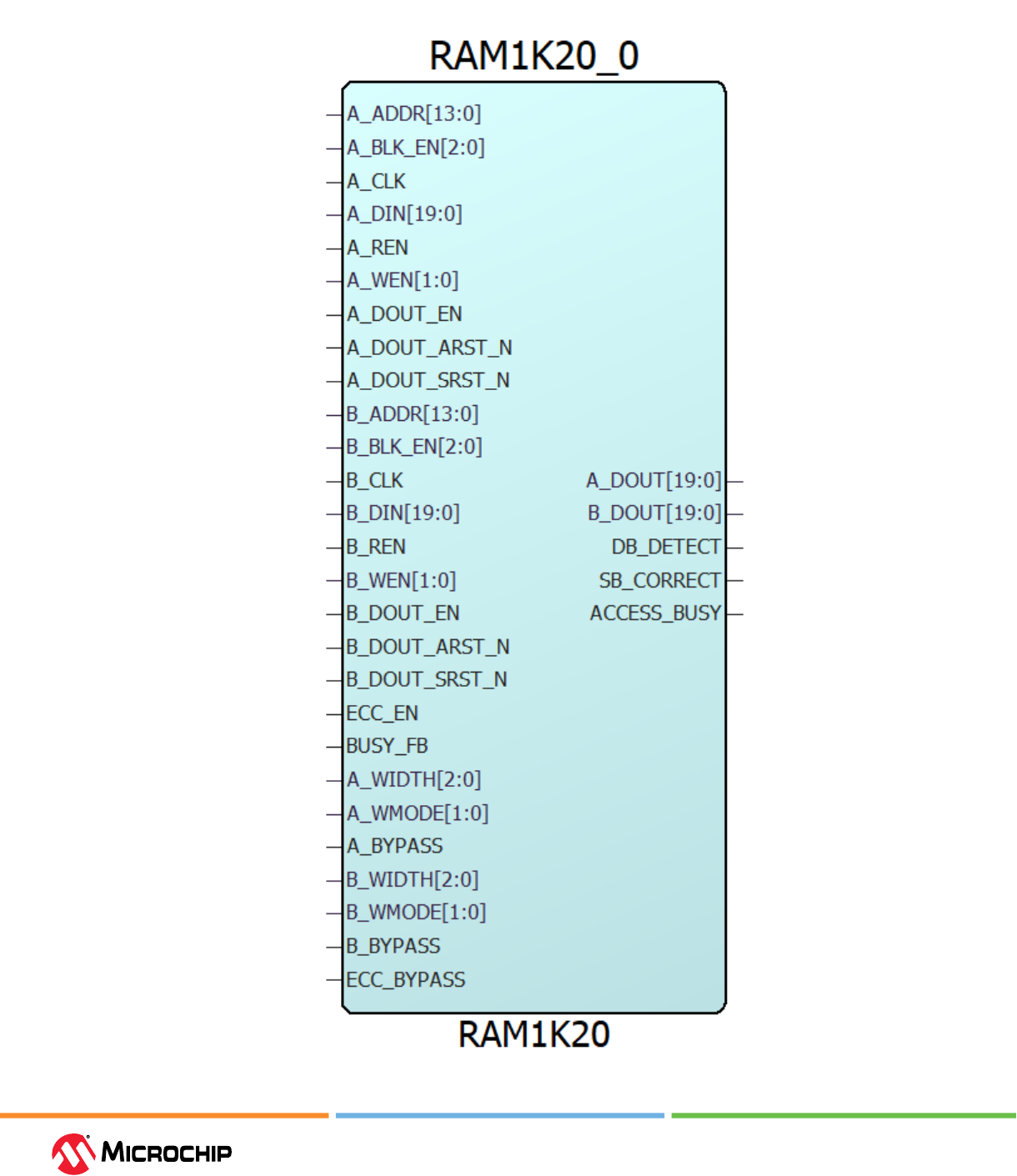

2.1 LSRAM (Ask a Queson)

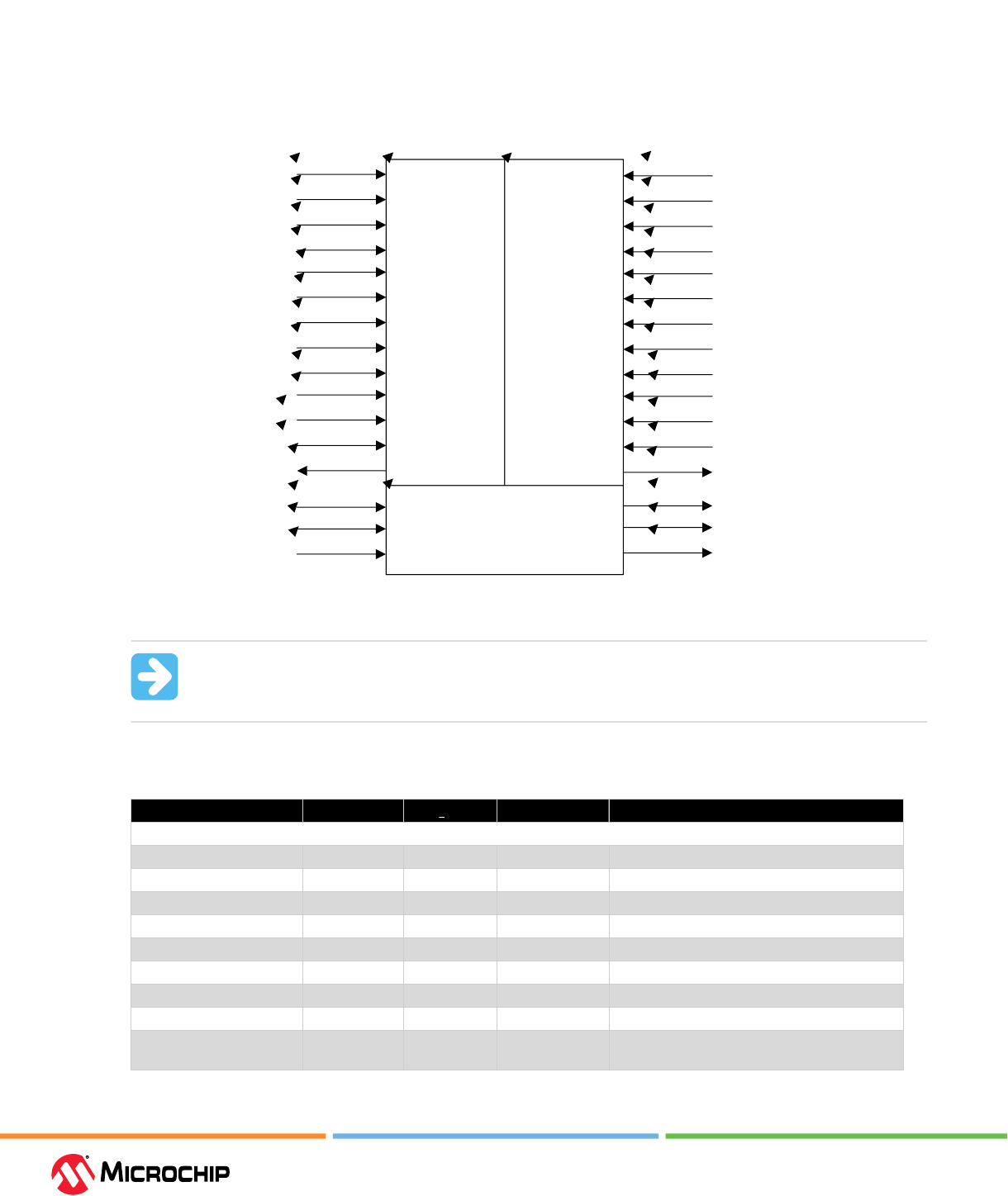

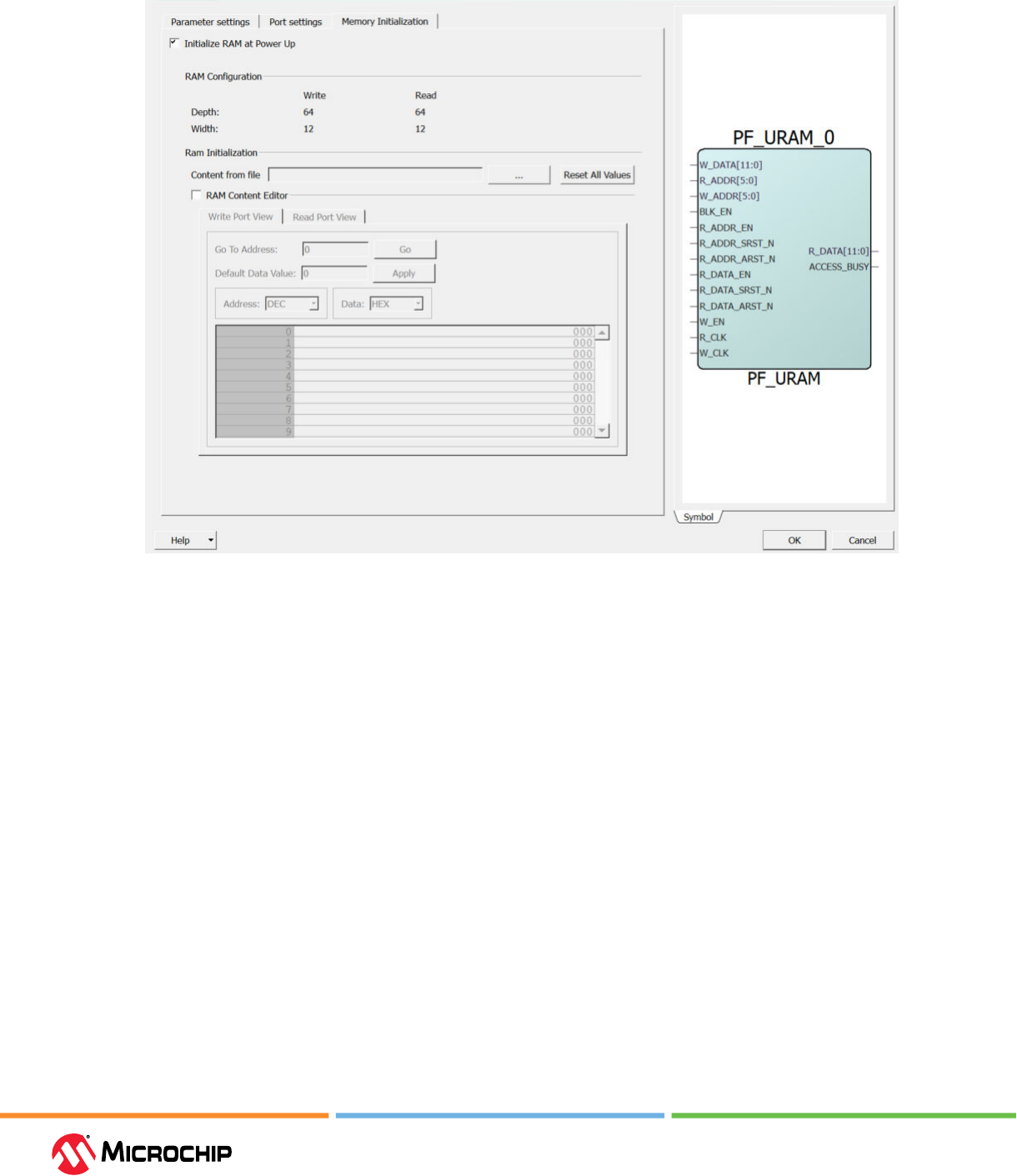

Each LSRAM has two independent ports—Port A and Port B, as shown in Figure 2-1. Both these ports

support write and read operations, and can be congured in dual-port mode or two-port mode.

Figure 2-1. LSRAM Input/Output

Port A Port B

Common Signals

A_ADDR[13:0]

A_BLK_EN[2:0]

A_CLK

A_DIN[19:0]

A_DOUT[19:0]

B_ADDR[13:0]

B_BLK_EN[2:0]

B_CLK

B_DIN[19:0]

B_DOUT[19:0]

A_WEN[1:0]

A_REN

A_WIDTH[2:0]

A_WMODE[1:0]

A_BYPASS

A_DOUT_EN

A_DOUT_SRST_N

A_DOUT_ARST_N

ECC_EN

ECC_BYPASS

BUSY_FB

B_WEN[1:0]

B_REN

B_WIDTH[2:0]

B_WMODE[1:0]

B_BYPASS

B_DOUT_EN

B_DOUT_SRST_N

B_DOUT_ARST_N

SB_CORRECT

DB_DETECT

ACCESS_BUSY

Important: When ECC is enabled, if a single-bit error occurs in a word, the data is

corrected. If multiple-bit errors occur in a word, the data from the LSRAM is not corrected

or modied.

The following table lists the ports of LSRAM.

Table 2-2. LSRAM Port List

Port Name Direction Type

1

Polarity Description

Port A

A_ADDR[13:0] Input Dynamic — Port A address

A_BLK_EN[2:0] Input Dynamic Active high Port A block selects

A_CLK Input Dynamic Rising edge Port A clock

A_DIN[19:0] Input Dynamic — Port A write-data

A_DOUT[19:0] Output Dynamic — Port A read-data

A_WEN[1:0] Input Dynamic Active high Port A byte write-enables

A_REN Input Dynamic Active high Port A read-enable

A_WIDTH[2:0] Input Static — Port A width/depth mode select

A_WMODE[1:0] Input Static Active high Port A read-before-write and feed-through

write selects

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 12

...........continued

Port Name Direction Type

1

Polarity Description

A_BYPASS Input Static Active high Port A read data pipeline register bypassed

when High

A_DOUT_EN Input Dynamic Active high Port A pipeline register enable

A_DOUT_SRST_N Input Dynamic Active low Port A pipeline register synchronous-reset

A_DOUT_ARST_N Input Dynamic Active low Port A pipeline register asynchronous-reset

Port B

B_ADDR[13:0] Input Dynamic — Port B address

B_BLK_EN[2:0] Input Dynamic Active high Port B block selects

B_CLK Input Dynamic Rising edge Port B clock

B_DIN[19:0] Input Dynamic — Port B write-data

B_DOUT[19:0] Output Dynamic — Port B read-data

B_WEN[1:0] Input Dynamic Active high Port B write-enables (per byte)

B_REN Input Dynamic Active high Port B read-enable

B_WIDTH[2:0] Input Static Mode select Port B width/depth

B_WMODE[1:0] Input Static Active high Port B read-before-write and feed-through

write selects

B_BYPASS Input Static Active high Port B read data pipeline register bypassed

when High

B_DOUT_EN Input Dynamic Active high Port B pipeline register enable

B_DOUT_SRST_N Input Dynamic Active low Port B pipeline register synchronous-reset

B_DOUT_ARST_N Input Dynamic Active low Port B pipeline register asynchronous-reset

Common Signals

ECC_EN Input Static Active high Enable ECC

ECC_BYPASS Input Static Active high ECC pipeline register bypassed when High.

SB_CORRECT Output Dynamic Active high Single-bit correct ag

DB_DETECT Output Dynamic Active high Dual-bit error detect ag

BUSY_FB Input Static Active high Lock access to SmartDebug

ACCESS_BUSY Output Dynamic Active high Busy signal from SmartDebug

Note:

1. Static inputs are tied to 0 or 1 during design implementation.

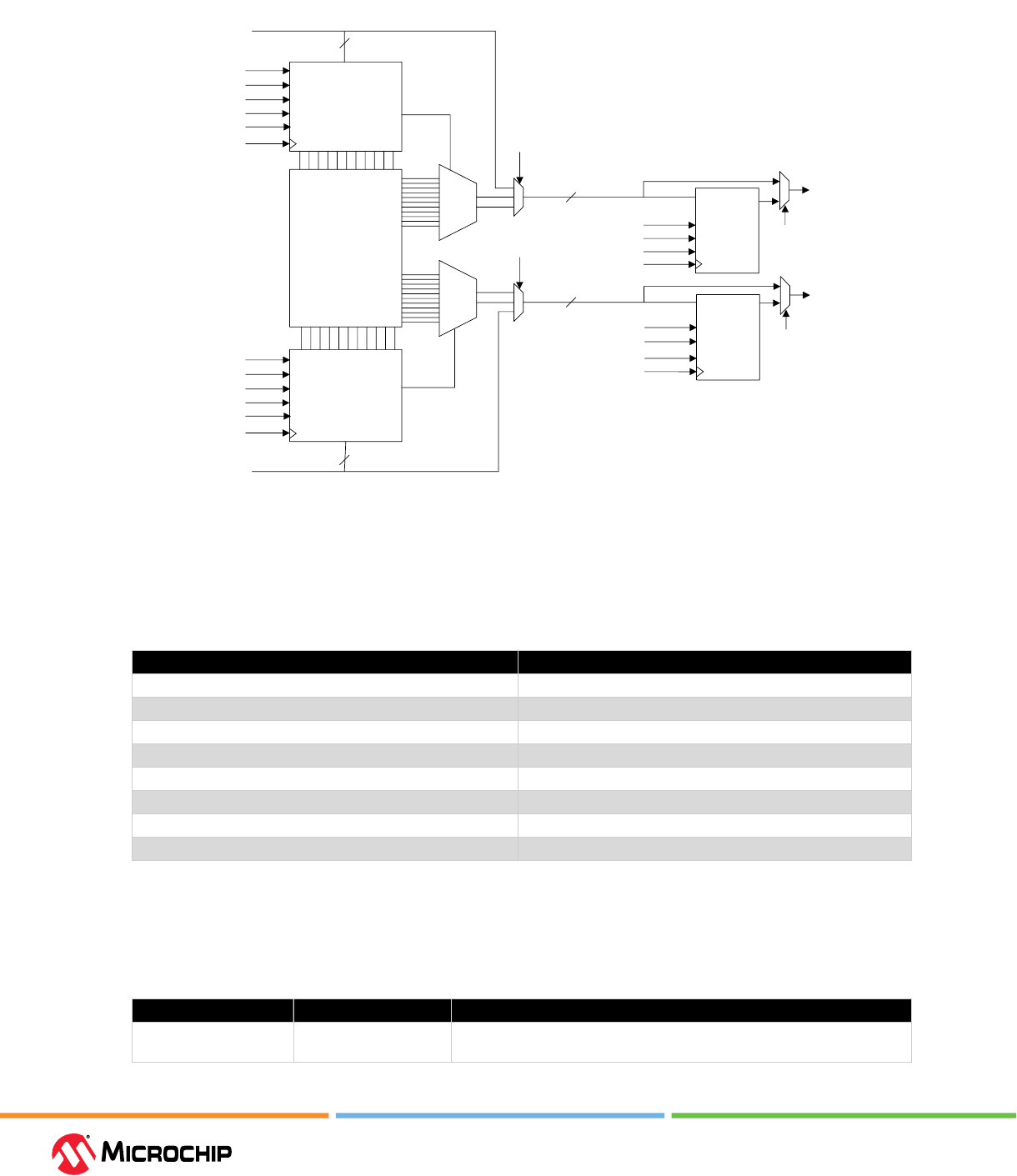

2.1.1 Dual-Port Mode (Ask a Queson)

The LSRAM block can be congured as a true dual-port SRAM with independent write and read

ports, as shown in Figure 2-2. Write and read operations can be performed from both ports (A

and B) independently at any location as long as there is no write collision. Each port has a unique

address, data in, data out, clock, block select, write enable, pipeline registers, and feed-through

MUXes.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 13

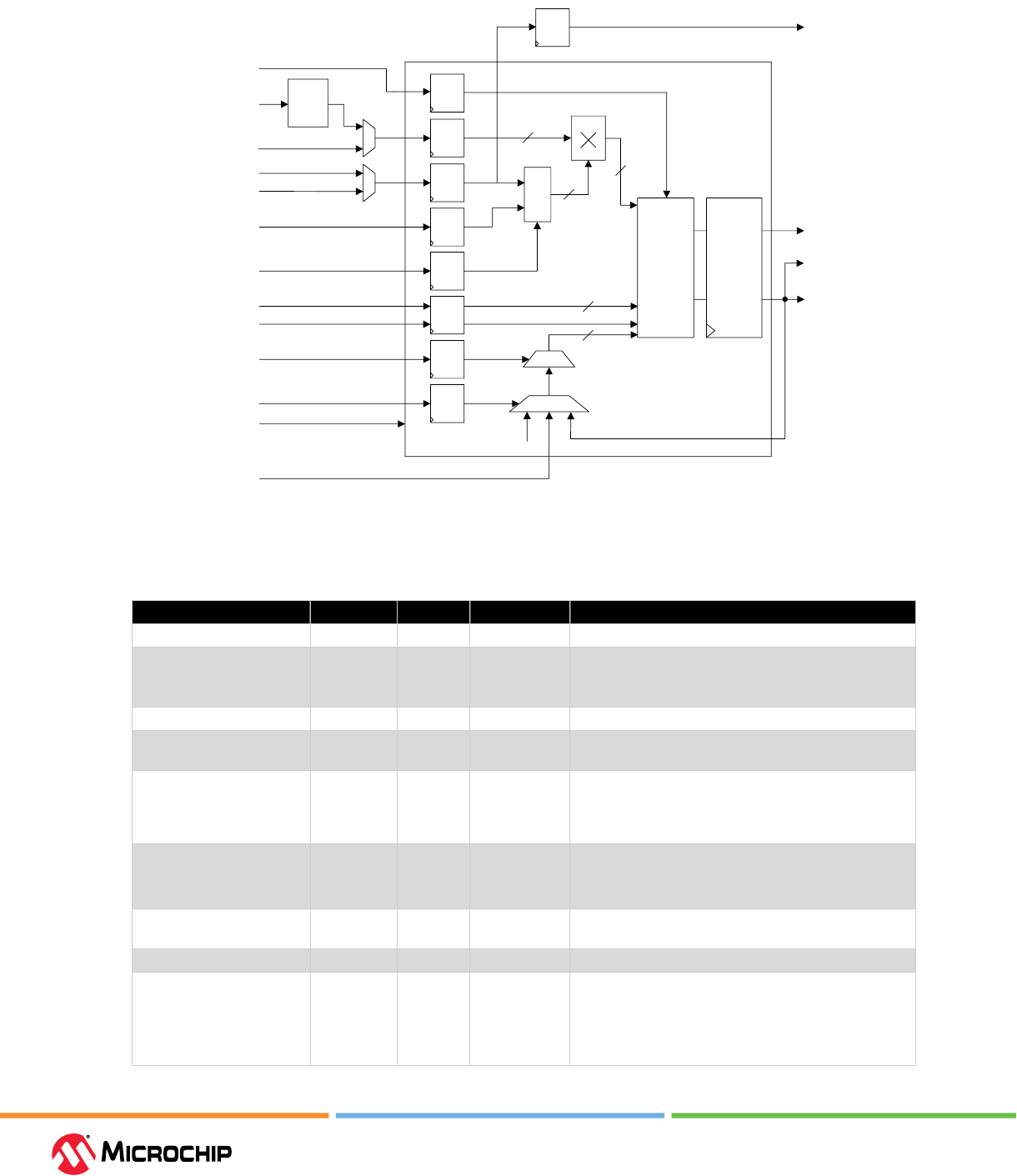

Figure 2-2. Simplied Funconal Block Diagram of LSRAM in Dual-Port Mode

A_DOUT[19:0]

A_DIN[19:0]

B_DIN[19:0]

A_ADDR[13:0]

A_WEN[1:0]

A_BLK_EN[2:0]

A_CLK

Port A Row Decode

Write Control

Port B Row Decode

Write Control

Column

Decode

Column

Decode

B_DOUT[19:0]

Memory Array

B_REN

B_DOUT_EN

A_REN

B_DOUT_ARST_N

B_DOUT_SRST_N

A_DOUT_EN

A_DOUT_SRST_N

A_DOUT_ARST_N

B_CLK

A_CLK

20

20

20

20

Pipeline

Register A

Pipeline

Register B

A_WIDTH[2:0]

A_WMODE[1:0]

B_ADDR[13:0]

B_WEN[1:0]

B_BLK_EN[2:0]

B_CLK

B_WIDTH[2:0]

B_WMODE[1:0]

A_BYPASS

B_BYPASS

2.1.1.1 Dual-Port Data Width Conguraon (Ask a Queson)

In Dual-Port mode, both ports A and B have maximum data width of x20. Each port can be

congured in multiple data widths. The conguration of one port has a corresponding conguration

for the other port, as shown in Table 2-3.

Table 2-3. Port A and Port B Data Width Conguraons for LSRAM

Port A Data Width Port B Data Width

x1 x1, x2, x4, x8, x16

x2 x1, x2, x4, x8, x16

x4 x1, x2, x4, x8, x16

x5 x5, x10, x20

x8 x1, x2, x4, x8, x16

x10 x5, x10, x20

x16 x1, x2, x4, x8, x16

x20 x5, x10, x20

2.1.1.2 Block Select Operaon (Ask a Queson)

In Dual-Port mode, to perform two independent write and read operations (on Port A, Port B, or

both) the block select signal is required. Table 2-4 lists the block select operation for Port A and Port

B.

Table 2-4. Block Select Operaon

A_BLK_EN[2:0] B_BLK_EN[2:0] Operation

Any one bit = 0 Any one bit = 0 No operation on Port A or B. The data output A_DOUT[19:0] and

B_DOUT[19:0] will be forced zero.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 14

...........continued

A_BLK_EN[2:0] B_BLK_EN[2:0] Operation

Any one bit = 0 111 Read or write operation on Port B

111 Any one bit = 0 Read or write operation on Port A

111 111 Read or write operation on both Ports A and B

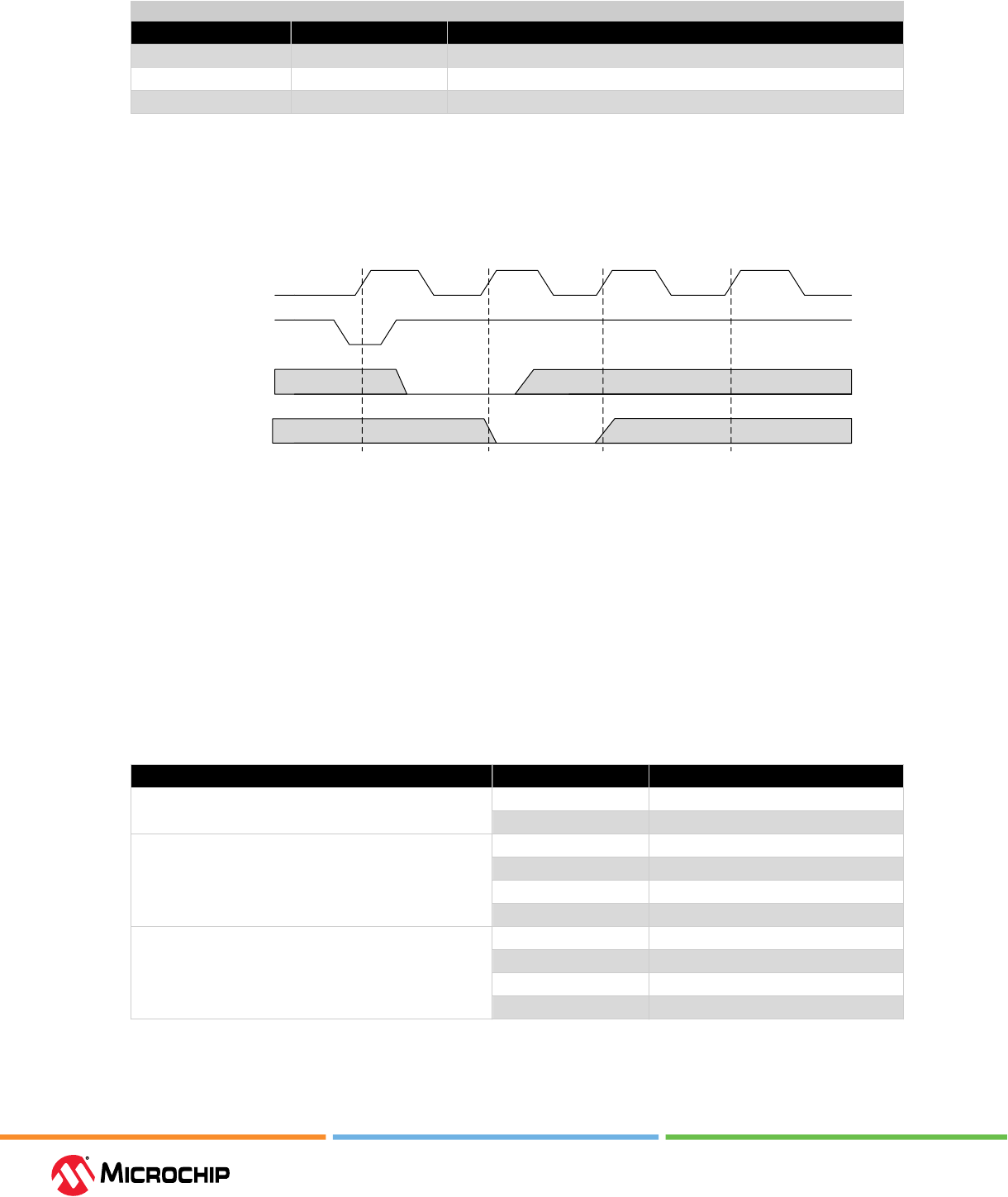

When the pipeline registers are enabled, the eect of the block select at the outputs is delayed by

one clock cycle, as shown in the following gure.

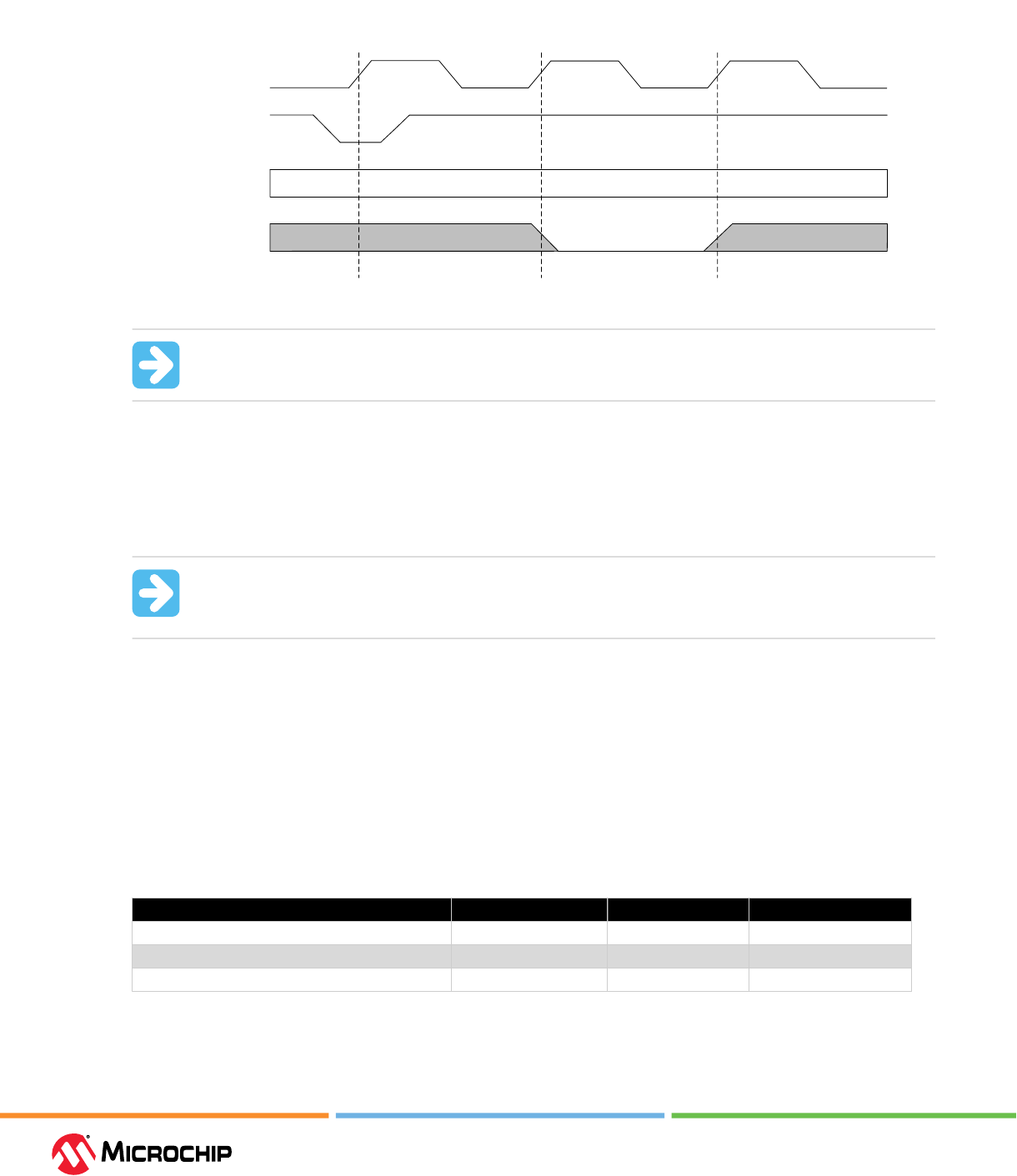

Figure 2-3. Block Select Inputs for Dual-Port Mode

A_CLK

B_CLK

A_BLK_EN

B_BLK_EN

Non-Pipeline Mode

B_DOUT[19:0]

A_DOUT[19:0]

B_DOUT[19:0]

A_DOUT[19:0]

Pipeline Mode

Clock Cycle #1 Clock Cycle #2 Clock Cycle #3

20'b0

20'b0

2.1.1.3 Byte Write Enables (Ask a Queson)

The byte write enables (A_WEN[1:0], B_WEN[1:0]) enable writing individual bytes of data for x20 and

x16 widths. The byte write enables for Port A (A_WEN[1:0]) enables A_DIN[19:10] and A_DIN[9:0]

respectively. The byte write enables for Port B (B_WEN[1:0]) enable B_DIN[19:10] and B_DIN[9:0]

respectively.

The byte write enables are also used in x1, x2, x4, x5, x8, x10, x16, and x20 widths to select the

operational mode (read/write) for a Port A or Port B. If all byte write enables are low, then Port A or

Port B is considered to be in read mode and any read operations are controlled by the read enables

(A_REN/B_REN).

Table 2-5 lists the byte write enable settings for Port A and Port B.

Table 2-5. Byte Write Enables Sengs for Dual-Port Mode

Depth x Width A_WEN/B_WEN Result

16K x 1, 8K x 2, 4K x 4, 4K x 5, 2K x 8, 2K x 10 00 or 10 Perform a read operation

01 or 11 Perform a write operation

1K x 16 00 Perform a read operation

01 Write [7:0]

10 Write [17:10]

11 Write [17:10], [7:0]

1K x 20 00 Perform a read operation

01 Write [9:0]

10 Write [19:10]

11 Write [19:0]

2.1.1.4 Read Enable (Ask a Queson)

The read enable signals, A_REN and B_REN, perform the read operation on ports A and B. When

read enable is low, the data outputs retain their previous state and no dynamic read power is

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 15

consumed on that port. When read enable is high, LSRAM performs read operations and consumes

read power.

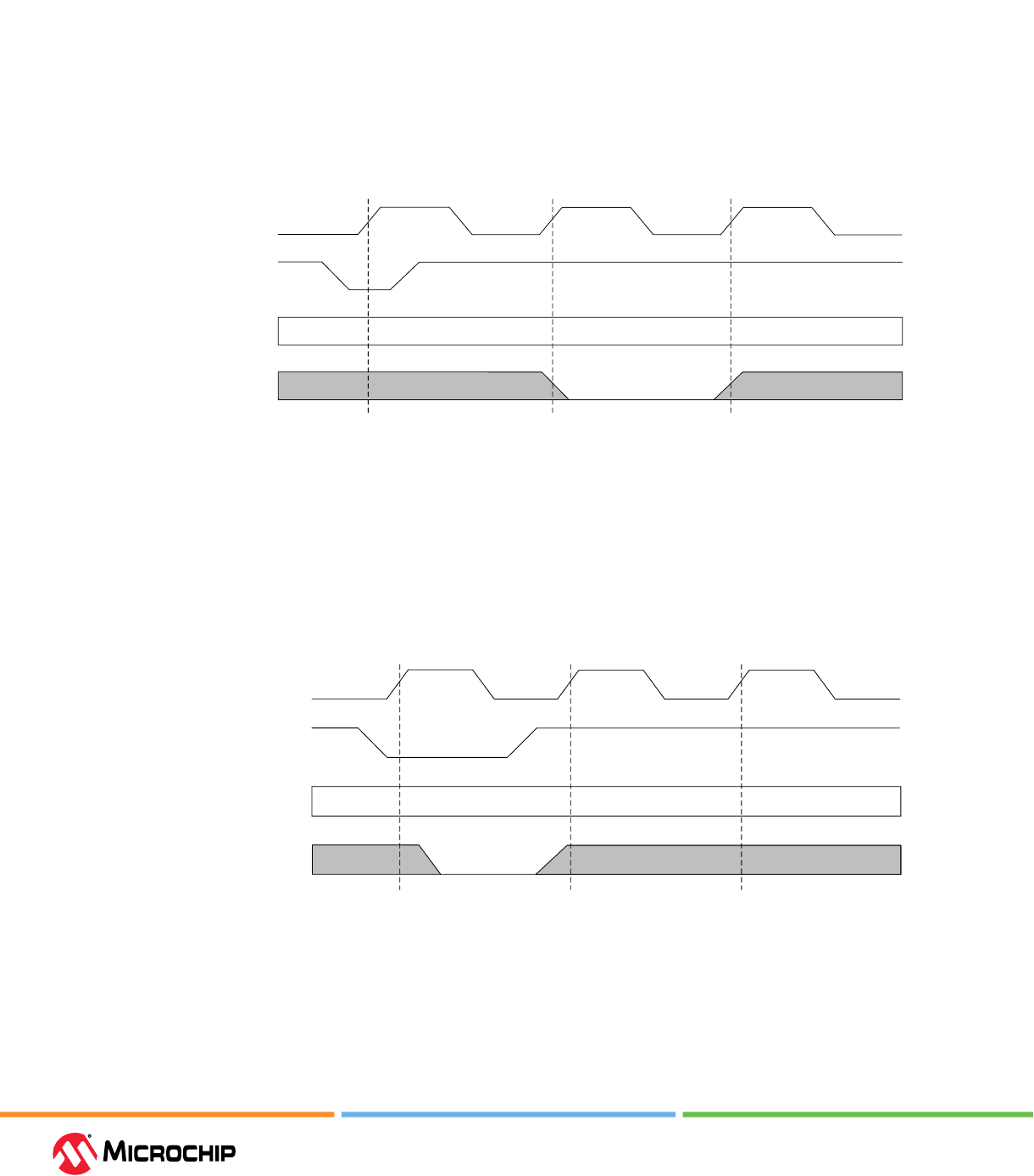

2.1.1.5 Synchronous Pipeline Register Reset (Ask a Queson)

Each pipeline register has one synchronous reset. In dual-port mode, A_DOUT_SRST_N and

B_DOUT_SRST_N drive the synchronous reset of the data output pipeline registers—A_DOUT and

B_DOUT. If the synchronous pipeline reset is low, the pipeline data output registers are reset to zero

on the next valid clock edge, as shown in the following gure.

Figure 2-4. Synchronous Pipeline Register Reset in Dual-Port Mode

A_CLK

B_CLK

A_DOUT_SRST_N

B_DOUT_SRST_N

A_DOUT[19:0]

B_DOUT[19:0]

A_DOUT[19:0]

B_DOUT[19:0]

Non-Pipeline Mode

Pipeline Mode

Clock Cycle #1 Clock Cycle #2

No Change

20'b0

2.1.1.6 Asynchronous Pipeline Register Reset (Ask a Queson)

Each pipeline register has one asynchronous reset. In dual-port mode, A_DOUT_ARST_N and

B_DOUT_ARST_N drive the asynchronous reset of the data output pipeline registers—A_DOUT and

B_DOUT. If the asynchronous pipeline reset is driven low, the pipeline data output registers are

immediately reset to zero, as shown in the following gure.

Figure 2-5. Asynchronous Pipeline Register Reset in Dual-Port Mode

A_CLK

B_CLK

A_DOUT[19:0]

B_DOUT[19:0]

A_DOUT[19:0]

B_DOUT[19:0]

Non-Pipeline Mode

Pipeline Mode

A_DOUT_ARST_N

B_DOUT_ARST_N

Clock Cycle #1 Clock Cycle #2

No Change

20'b0

2.1.1.7 Read Operaon (Ask a Queson)

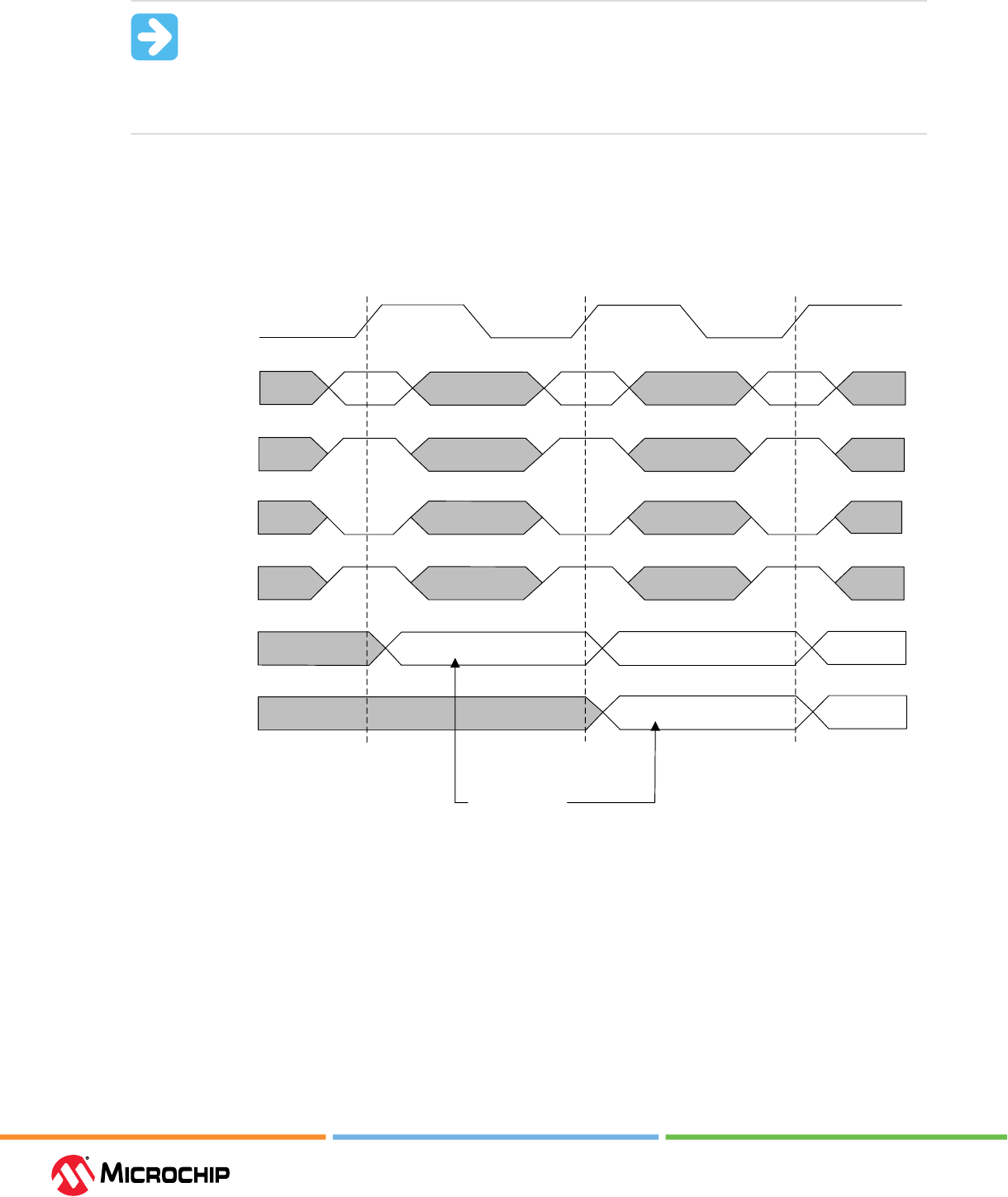

In dual-port mode, LSRAM supports both pipelined and non-pipelined read operations. In a

pipelined read operation, the output data is registered at the pipeline registers; as a result the

data is available on the corresponding data output on the next clock cycle.

In a non-pipelined read operation, the pipeline registers are bypassed and read data is available on

the output port in the same clock cycle.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 16

Important:

• For high-performance designs, It is recommended to use the LSRAM with pipeline mode

to meet the design timing constraints.

• When multiple depth-cascaded blocks are used, A_REN and B_REN ports of Dual-Port

SRAM are disabled by the congurator GUI.

The following gure shows the timing for both pipelined and non-pipelined read operations in the

Dual-Port mode.

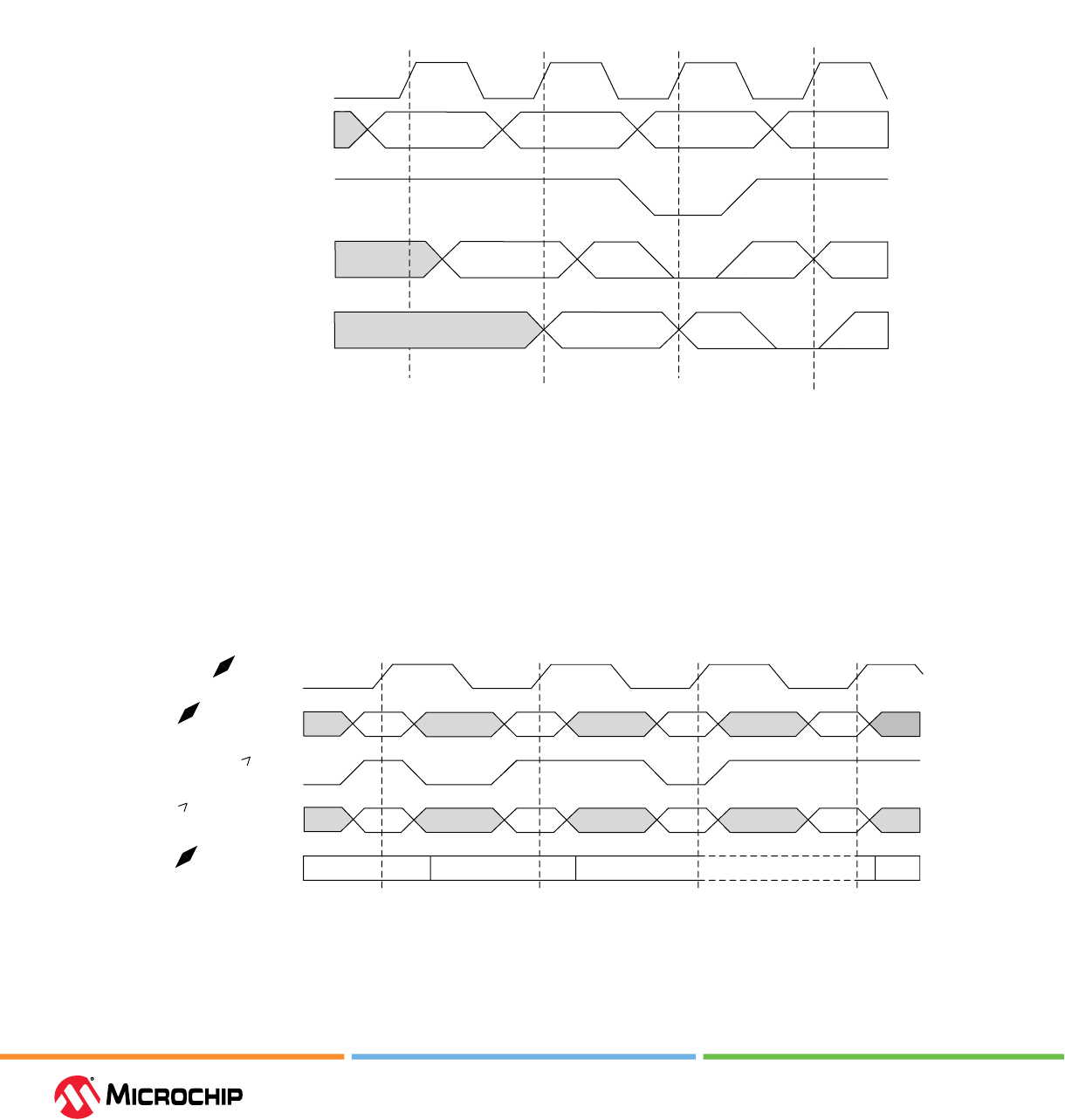

Figure 2-6. Read Operaon in Dual-Port Mode

A_REN

B_REN

A_CLK

B_CLK

A_WEN[1:0]

B_WEN[1:0]

A_ADDR[13:0]

B_ADDR[13:0]

A_DOUT_EN

B_DOUT_EN

A_DOUT[19:0]

B_DOUT[19:0]

A_DOUT[19:0]

B_DOUT[19:0]

Pipeline Mode

Non-Pipeline Mode

Clock Cycle #1 Clock Cycle #2

Data in address A0

D(A0)

D(A1)

D(A2)

D(A0)

D(A1)

A0

A1

A2

2.1.1.8 Write Operaon (Ask a Queson)

In dual-port mode, LSRAM supports the following write operations:

• 2.1.1.8.1. Simple Write

• 2.1.1.8.2. Feed-Through Write

• 2.1.1.8.3. Read-Before-Write

The type of write operation is specied while creating or conguring LSRAM in Libero SoC. For more

information on LSRAM conguration, see 2.1.3.2. LSRAM Congurator

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 17

Note: In dual-port mode, simultaneous write operations from both ports to the same address

location are not prevented. As simultaneous write operations can result in data uncertainty, it is

recommended to use external logic in the fabric to avoid collisions.

2.1.1.8.1 Simple Write (Ask a Queson)

In a simple-write operation, data input A_DIN and B_DIN are written to the corresponding address

locations A_ADDR and B_ADDR. The data written to the memory is available at the output only after

performing a read operation.

2.1.1.8.2 Feed-Through Write (Ask a Queson)

In a feed-through write operation for pipelined operations, the read data is available on the data

output bus on the next clock cycle. For non-pipelined operations, data written to the memory is

available in the same clock cycle on the corresponding data output bus. For more information, see

Figure 2-7.

In dual-port mode during feed-through write, the data output of each port can change in one of the

following ways:

• During read port reset, the data output becomes zero.

• If the block select input (A_BLK_EN) of Port A or B is driven low, then the corresponding port's

data output becomes zero.

• During valid write operations when read enable (A_REN and B_REN) is high, then write data is

available at the data output.

• If there is a valid read operation, then the read data is available at the data output. A valid

read happens when read enable (A_REN and B_REN) inputs are high, and byte write enable

(A_WEN[1:0] and B_WEN[1:0]) inputs are zero.

2.1.1.8.3 Read-Before-Write (Ask a Queson)

In a read-before-write operation for pipeline mode, read data is available on the data output bus

on the next clock cycle. For non-pipeline mode, the previous memory data from the current write

address is available on the data output before the new data is written to the address location. For

more information, see Figure 2-7.

In Dual-Port mode during read-before-write operations, the data output of each port can change in

one of the following ways:

• During read port reset, the data output becomes zero.

• If the block select input (A_BLK_EN) of Port A or B is driven low, then the corresponding port's

data output becomes zero.

• During valid write operations when read enables (A_REN and B_REN) are driven high, the previous

memory data from the current address is available on the data output before the new data is

written to the address location.

• If there is a valid read operation, then the read data is available on the data output. A valid read

happens when read enable (A_REN and B_REN) inputs are driven high, and byte write enable

(A_WEN[1:0] and B_WEN[1:0]) inputs are driven low.

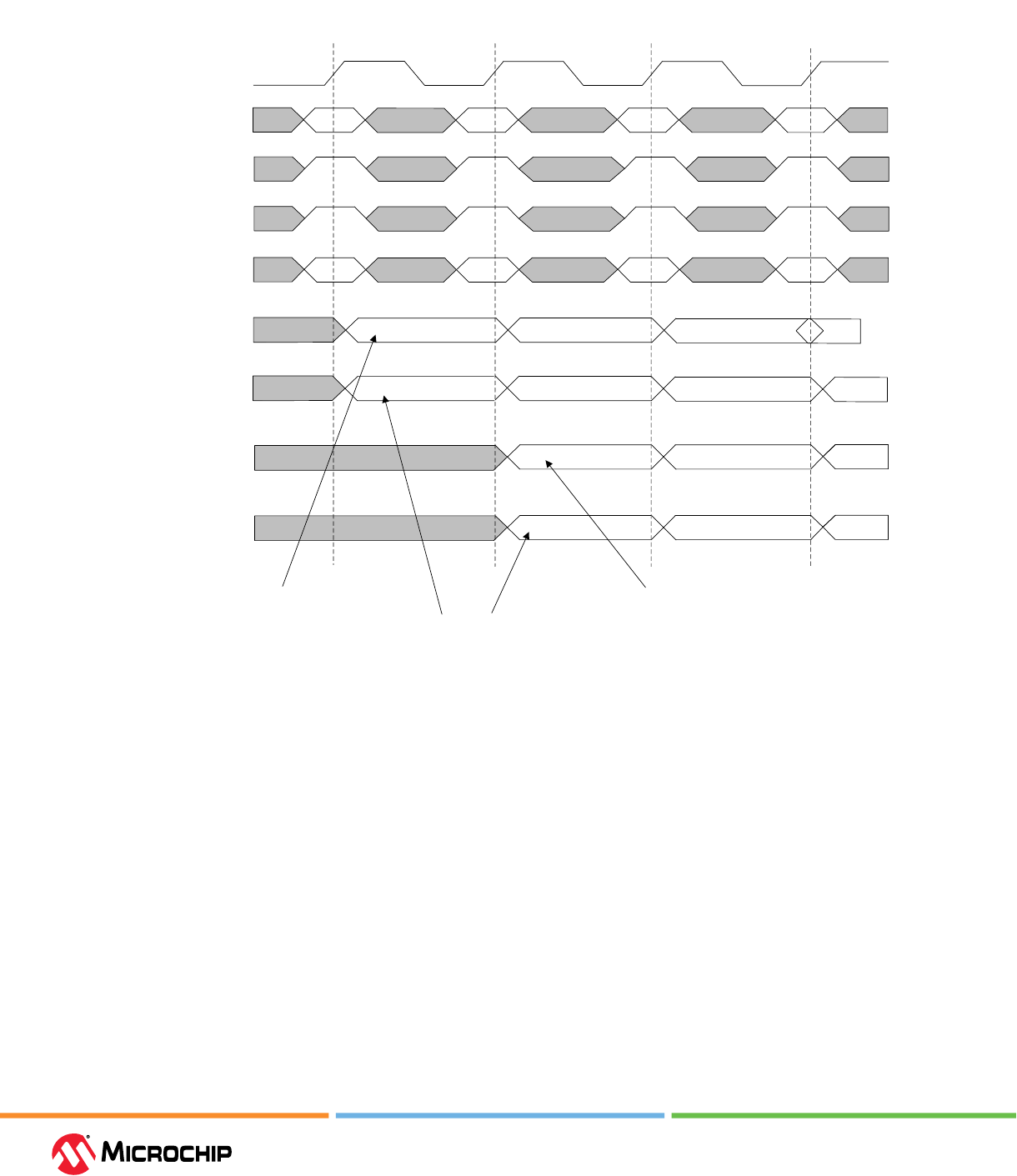

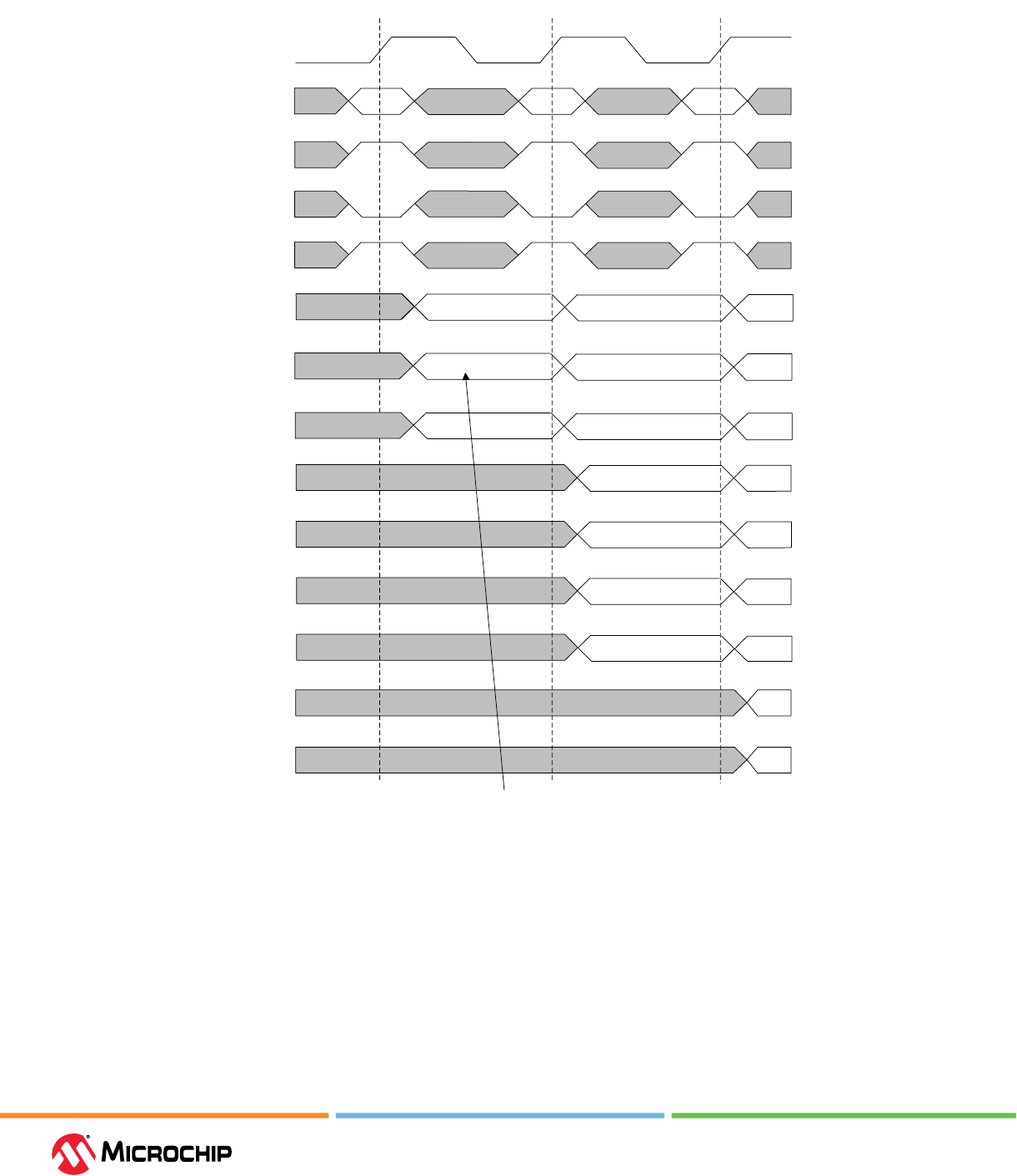

The following gure shows the timing for feed-through-write and read-before-write operations for

Dual-Port mode.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 18

Figure 2-7. Write Operaons in Dual-Port Mode

A_CLK

B_CLK

A_ADDR[]

B_ADDR[]

A_DOUT_EN

B_DOUT_EN

A_WEN[1:0]

B_WEN[1:0]

A_DIN[]

B_DIN[]

A_DOUT[]

B_DOUT[]

A_DOUT[]

B_DOUT[]

Feed-Through Write Pipeline Mode

Feed-Through Write Non-Pipeline Mode

D0

Clock Cycle #1 Clock Cycle #2 Clock Cycle #3

D3

D0

D1 D2 D3

D0

D1

D2

A_DOUT[]

B_DOUT[]

A_DOUT[]

B_DOUT[]

Read Before Write Pipeline Mode

Read Before Write Non-Pipeline Mode

Previous data in Address A0

Current write data in Address A0

Current write data in Address A0

D1

A0

A1 A2 A3

D2

D(A0)

D(A3)

D(A1)

D(A2)

D(A0)

D(A1)

D(A2)

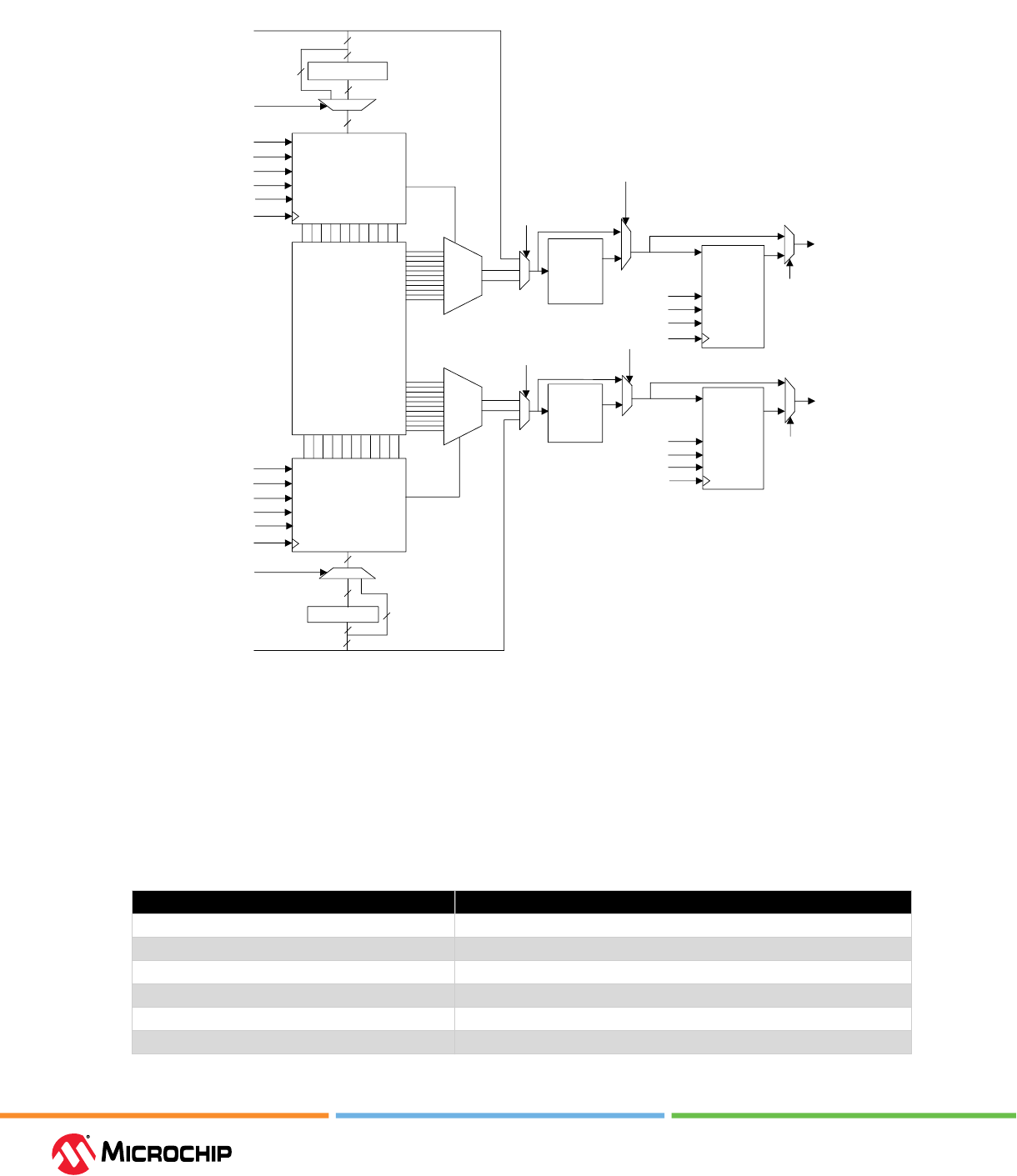

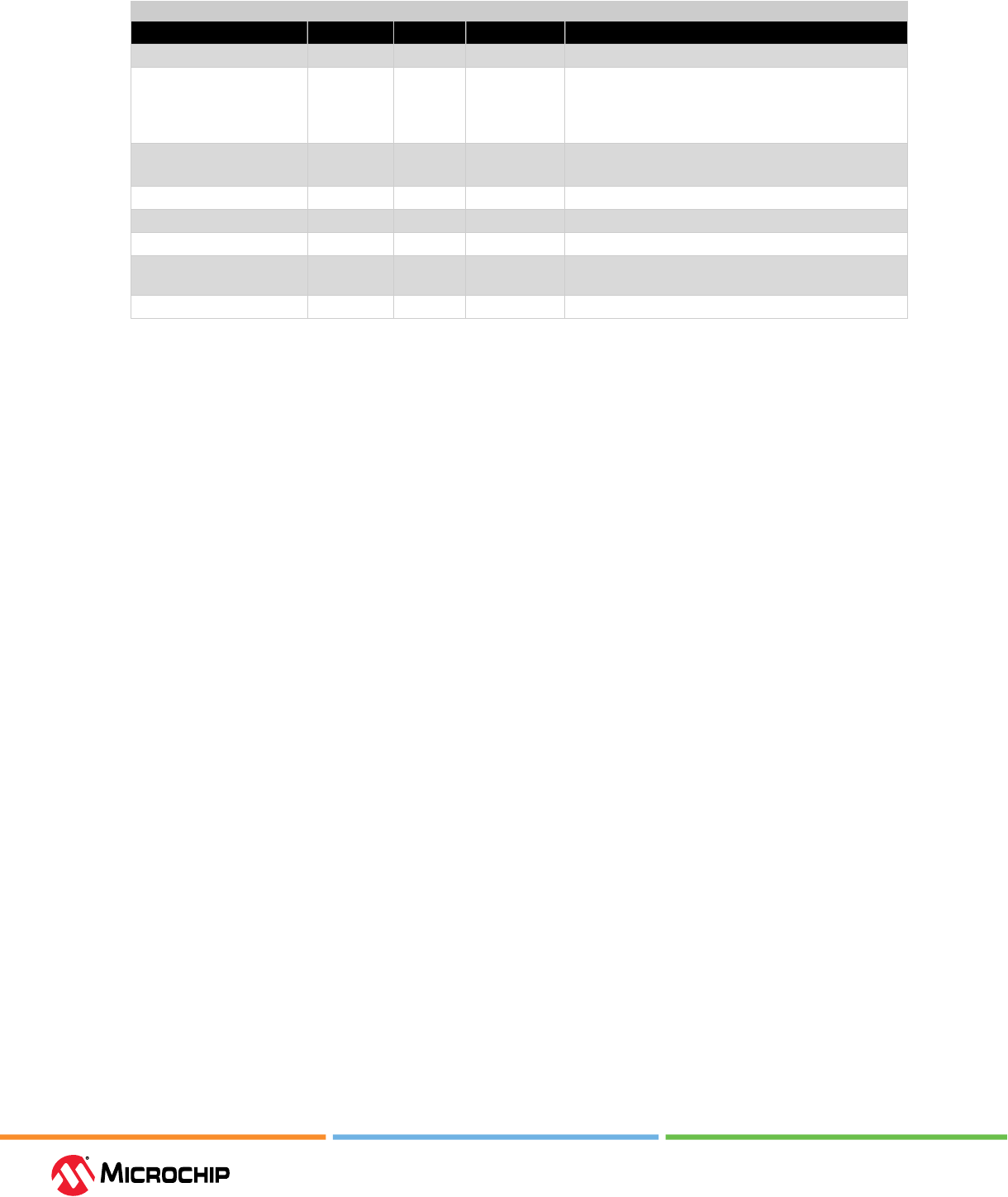

2.1.2 Two-Port Mode (Ask a Queson)

The LSRAM block can be congured as a Two-Port SRAM, where Port A is dedicated to read

operations and Port B is dedicated to write operations for data widths up to x20. For data widths

greater than x20, the read port borrows the unused Port B data output signals, similarly write port

borrows the unused Port A data input signals. Figure 2-8 shows the LSRAM in Two-Port mode with

independent write and read ports, pipeline registers, ECC logic, and feed-through MUXes to enable

immediate access to the write data. The ECC is supported only when the LSRAM is congured for

33-bit data width.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 19

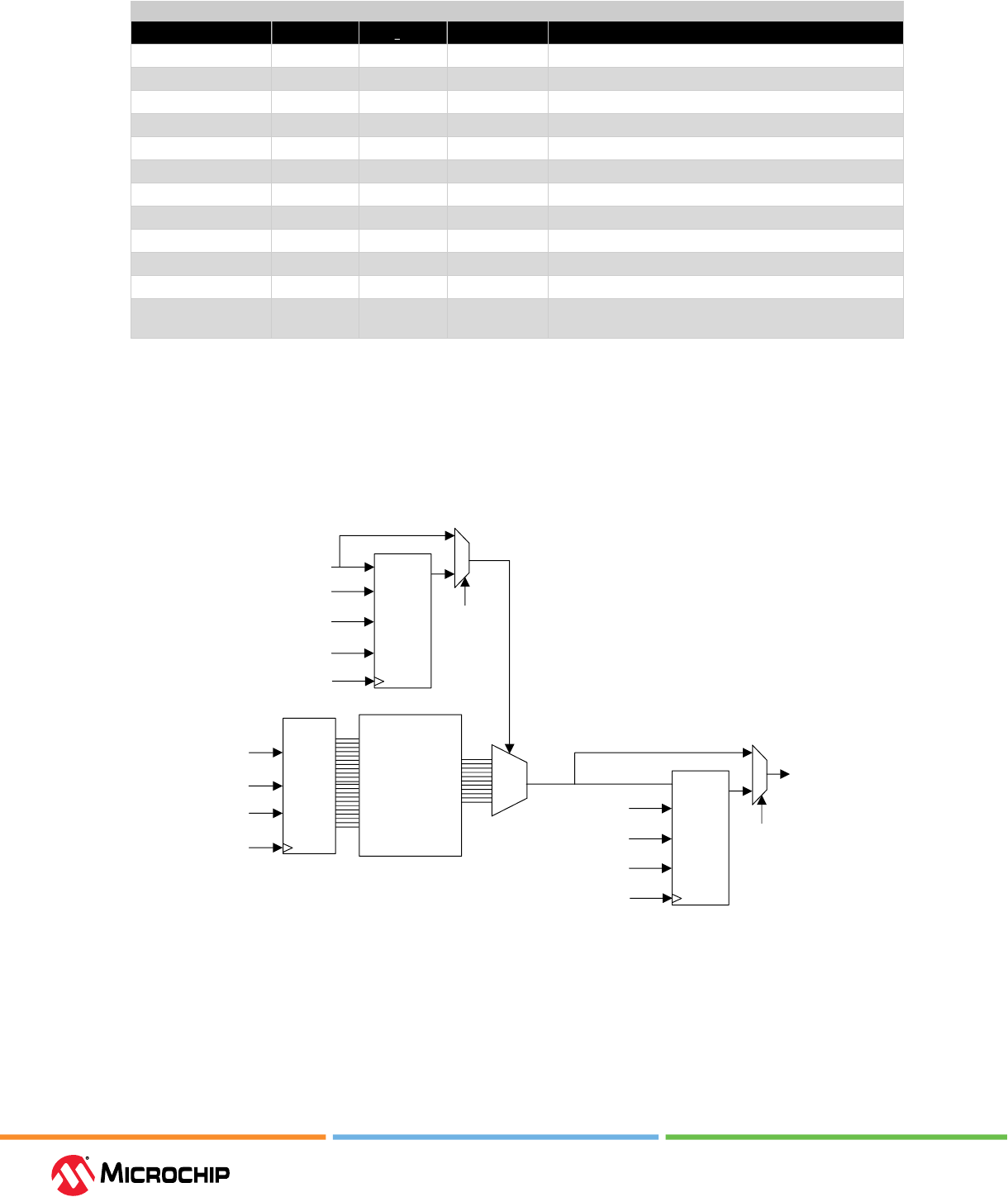

Figure 2-8. Simplied Funconal Block Diagram for LSRAM in Two-Port Mode

A_DOUT[19:0]*

A_DIN[19:0]*

B_DIN[19:0]*

A_ADDR[13:0]

A_WEN[1:0]

A_BLK_EN[2:0]

A_CLK

Port A Row Decode

Write Control

Port B Row Decode

Write Control

Column

Decode

Column

Decode

B_DOUT[19:0]*

Memory Array

B_DOUT_EN

B_DOUT_ARST_N

B_DOUT_SRST_N

A_DOUT_EN

A_DOUT_SRST_N

A_DOUT_ARST_N

B_CLK

A_CLK

20

Pipeline

Register A

Pipeline

Register B

A_WIDTH[2:0]

B_ADDR[13:0]

B_WEN[1:0]

B_BLK_EN[2:0]

ECC_EN

B_WIDTH[2:0]

ECC Encoder

20

ECC Encoder

ECC_EN

16 data and

4 ECC code bits

17 data and

3 ECC code bits

20

17

16

ECC

Decoder

+

Pipeline

Registers

ECC

Decoder

+

Pipeline

Registers

B_CLK

B_WMODE[1:0]

A_WMODE[1:0]

B_REN

A_REN

20

20

ECC_EN

ECC_EN

Note:

* For ECC mode:

A_DIN[15:0] and B_DIN[16:0]

A_DOUT[15:0] and B_DOUT[16:0]

20/17

A_BYPASS

B_BYPASS

2.1.2.1 Two-Port Data Width Conguraon (Ask a Queson)

In Two-Port mode, the maximum data width is x40. Each port can be congured in dierent data

widths. The conguration of read port has a corresponding conguration for the write port, as

shown in Table 2-6.

Table 2-6. LSRAM Data Width Conguraons (Two-Port Mode)

Read Port Write Port

x40 x5, x10, x20, x40

x20 x40

x10 x40

x5 x40

x2 x32

x1 x32

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 20

...........continued

Read Port Write Port

x33 x33

x32 x1, x2, x32

2.1.2.2 Byte Write Enables (Ask a Queson)

The byte write enables (A_WEN, B_WEN) enable writing individual bytes of data for x32, x33 and x40

data widths. For x40 width, the byte write enable for the corresponding data is used to enable each

of the four bytes; that is, byte write enable for Port A enables A_DIN[19:10] and A_DIN[9:0] and byte

write enable for Port B enables B_DIN[19:10] and B_DIN[9:0].

Table 2-7 lists the byte write enable settings for Port A and Port B.

Table 2-7. Byte Write Enable Sengs for Two-Port Mode

Depth x Width A_WEN/B_WEN Result

512 x 32 B_WEN[0] = 1 Write B_DIN[8:5], B_DIN[3:0]

B_WEN[1] = 1 Write B_DIN[18:15], B_DIN[13:10]

A_WEN[0] = 1 Write A_DIN[8:5], A_DIN[3:0]

A_WEN[1] = 1 Write A_DIN[18:15], A_DIN[13:10]

512 x 40 B_WEN[0] = 1 Write B_DIN[9:0]

B_WEN[1] = 1 Write B_DIN[19:10]

A_WEN[0] = 1 Write A_DIN[9:0]

A_WEN[1] = 1 Write A_DIN[19:10]

512 x 33 (with ECC Enabled) B_WEN[1:0] = 11

A_WEN[1:0] = 11

Write B_DIN[16:0]

Write A_DIN[15:0]

Important: For 512x32 conguration, bits 4, 9, 14, and 19 of data input ports are not used.

2.1.2.3 Read Enables (Ask a Queson)

The read enable signals, A_REN and B_REN, perform the read operation on ports A and B. When

read enable is low, the data outputs retain their previous state and no dynamic read power is

consumed on that port. When read enable is high, LSRAM performs read operation and consumes

read power.

Important: In Two-Port mode, LSRAM Port B read enable (B_REN) is tied to Port A read

enable (A_REN).

2.1.2.4 Pipeline Registers (Ask a Queson)

The outputs of the LSRAM have pipeline registers which can be enabled by the user for timing

closure. These pipeline registers can be reset synchronously or asynchronously as explained in the

following section.

2.1.2.4.1 Synchronous Pipeline Register Reset (Ask a Queson)

Each data output port has its own synchronous reset. In Two-Port mode, A_DOUT_SRST_N and

B_DOUT_SRST_N drive the synchronous reset of the read data output pipeline registers (A_DOUT

and B_DOUT). If the synchronous pipeline reset is low, the pipeline data output registers are reset to

zero on the next valid clock edge, as shown in the following gure.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 21

Figure 2-9. Synchronous Pipeline Reset in Two-Port Mode

A_CLK

B_CLK

A_DOUT_SRST_N

B_DOUT_SRST_N

A_DOUT[]

B_DOUT[]

SB_CORRECT

B_DETECT

A_DOUT[]

B_DOUT[]

SB_CORRECT

B_DETECT

Non-Pipeline Mode With/without ECC

Pipeline Mode with/without ECC

Clock Cycle #1 Clock Cycle #2

No Change

20'b0

Important: In x33 two-port mode, if ECC is in pipeline mode, this reset also resets the ECC

ag pipeline registers.

2.1.2.5 ECC Mode (For x33 Two-Port Mode Only) (Ask a Queson)

In the Two-Port mode, when the port width is set to x33, ECC (single-bit error correction and dual-bit

error detection) is available. The ECC encoder provides 40 bits (33 data bits and 7 encoded data

bits) of data in the x33 mode (the seven encoded bits are not accessible to the user). Single-bit and

dual-bit errors are counted for a full 33-bit read data word.

Important: ECC is supported only in two-port LSRAM congurations and not supported

for RTL inferred RAM blocks. For information about ECC conguration settings, see Figure

2-18.

The ECC decoder contains an optional pipeline register that adds a clock cycle of latency to the read

operation (including the ags). As the output data can also be pipelined, there are four possible

scenarios:

• Pipeline mode with non-pipelined ECC

• Pipeline mode with pipelined ECC

• Non-Pipeline mode with non-pipelined ECC

• Non-Pipeline mode with pipelined ECC

The following table lists the two ags generated by the ECC logic.

Table 2-8. Error Flags

ECC Errors SB_CORRECT DB_DETECT Correction

No error 0 0 NA

Single-bit error 1 0 Correction

Double-bit or Multi-bit error 1 1 No correction

Any multiple bit errors greater than one has both ags asserted, and the 33-bit read data word

not corrected. No scrubbing is done inside the LSRAM when ECC decoder detects any bit errors. All

scrubbing must be done in the fabric design. ECC simulation is not supported.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 22

In the Pipeline mode, these ags are valid only in the read data output clock cycle. In Non-Pipeline

mode, the ECC ags are valid only in the same clock cycle as the corresponding read data output, as

the ags are reset in the next clock cycle.

In SmartDebug, the ECC bits are included in the 40 bits data divided between adjacent locations. 16

bits of data in one location and 17 bits of data in the next location, the remaining 5 bits are ECC

bits. The ECC bits are pre-calculated by Libero SoC and loaded in the background with the SRAM

initialization data. For information about loading the initializing client for the SRAM memory IP in

Libero SoC, see PolarFire Family Power-Up and Resets User Guide.

2.1.2.6 Read Operaon (Ask a Queson)

In two-port mode, LSRAM supports both pipelined and non-pipelined read operations. In a pipelined

read operation, the output data is registered at the pipeline registers making the data available

on the corresponding data output on the next clock cycle. If the ECC pipeline mode is enabled, an

additional clock cycle is required for read data output. ECC ags are valid in the same clock cycle as

the output data. For more information, see 2.1.2.5. ECC Mode (For x33 Two-Port Mode Only).

In non-pipelined read operations, the pipeline registers are bypassed and read data is available on

the output port in the same clock cycle. During this operation, LSRAM can generate glitches on

the data output buses. Therefore, it is recommended to use LSRAM with pipeline registers to avoid

glitches.

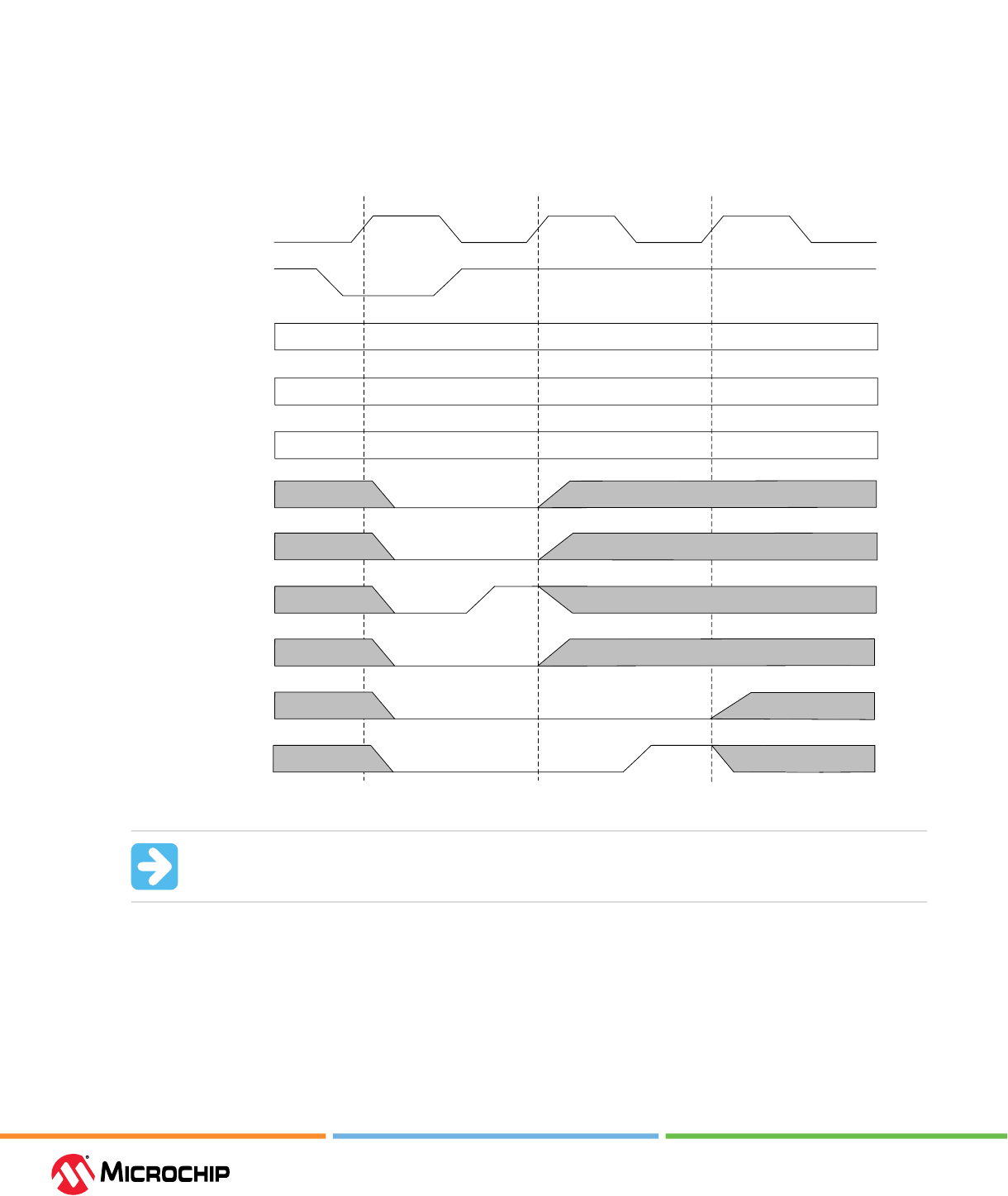

The following gure shows the timing for both pipelined and non-pipelined read operations in

two-port mode.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 23

Figure 2-10. Read Operaon in Two-Port Mode

A_REN

B_REN

A_CLK

B_CLK

A_WEN[1:0]

B_WEN[1:0]

A_ADDR[]

B_ADDR[]

A_DOUT_EN

B_DOUT_EN

A_DOUT[]

B_DOUT[]

A_DOUT[]

B_DOUT[]

A_DOUT[]

B_DOUT[]

A_DOUT[]

B_DOUT[]

A_DOUT[]

B_DOUT[]

Non-Pipeline Mode with Non-Pipelined ECC

Non-Pipeline Mode without ECC

Pipeline Mode with Non-Pipelined ECC

Pipeline Mode with Pipelined ECC

Non-Pipeline Mode with Pipelined ECC

A0

A1 A2

Clock Cycle #1 Clock Cycle #2

D(A1)

D(A1)

D(A0)

D(A0)

D(A0)

SB_CORRECT

DB_DETECT

Non-Pipeline Mode with Non-Pipelined ECC

SB_CORRECT

DB_DETECT

Pipeline Mode with Non-Pipelined ECC

SB_CORRECT

DB_DETECT

Non-Pipeline Mode with Pipelined ECC

SB_CORRECT

DB_DETECT

Pipeline Mode with Pipelined ECC

Data in Address A0

D(A2)

D(A0)

D(A1)

D(A2)

D(A0)

D(A1)

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 24

2.1.2.7 Asynchronous Pipeline Register Reset (Ask a Queson)

Each data output port has its own asynchronous reset. In Two-Port mode, A_DOUT_ARST_N and

B_DOUT_SRST_N drive the asynchronous reset of the read data output pipeline registers (A_DOUT

and B_DOUT) and ECC pipeline registers. If the asynchronous pipeline reset is driven low, the

pipeline data output registers are immediately reset to zero, as shown in the following gure.

Figure 2-11. Asynchronous Pipeline Register Reset in Two-Port Mode

A_CLK

B_CLK

A_DOUT_ARST_N

B_DOUT_ARST_N

A_DOUT[19:0]

B_DOUT[19:0]

A_DOUT[15:0]

B_DOUT[16:0]

SB_CORRECT

B_DETECT

SB_CORRECT

DB_DETECT

A_DOUT[15:0]

B_DOUT[16:0]

SB_CORRECT

DB_DETECT

A_DOUT[15:0]

B_DOUT[16:0]

A_DOUT[15:0]

B_DOUT[16:0]

Pipeline Mode with Pipelined ECC

Pipeline Mode with Pipelined ECC

Pipeline Mode with Non-Pipelined ECC

Non-Pipeline Mode with Pipelined ECC

Non-Pipeline Mode with Pipelined ECC

Pipeline Mode without ECC

Non-Pipeline Mode with Non-Pipelined ECC

Non-Pipeline Mode with Non-Pipelined ECC

Non-Pipeline Mode without ECC

Clock Cycle #1 Clock Cycle #2

A_DOUT[19:0]

B_DOUT[19:0]

20'b0

Important: In x33 Two-Port mode, if ECC is in pipeline mode, then this reset also resets

the ECC ag pipeline registers.

2.1.3 Implementaon (Ask a Queson)

An LSRAM block is implemented in a design using the following methods:

• 2.1.3.1. RTL Inference during Synthesis

• 2.1.3.2. LSRAM Congurator

• 2.1.3.3. LSRAM Memory Macro

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 25

2.1.3.1 RTL Inference during Synthesis (Ask a Queson)

Synplify Pro ME can infer an LSRAM from RTL automatically based on memory logic used in the

design. In this case, synthesis handles all the signal connections of the LSRAM block to the rest of

the design and sets the correct values for the static signals needed to congure the appropriate

operational mode. The tool ties unused dynamic input signals to ground and provides default values

to unused static signals. If a design requires more memory blocks than the blocks available in the

device, the Synthesis tool will infer fabric registers for the extra memory blocks.

For more information about LSRAM inference by Synplify Pro, see Inferring PolarFire RAM Blocks

Application Note.

2.1.3.2 LSRAM Congurator (Ask a Queson)

The Libero SoC software catalog has the following LSRAM conguration tools:

• 2.1.3.2.1. Dual-Port Large SRAM Congurator

• 2.1.3.2.2. Two-Port LSRAM Congurator

Using these congurators, the LSRAM can be congured as per design requirements. The generated

LSRAM component can be instantiated in the SmartDesign. The congurators generate the HDL

wrapper les for LSRAM with the appropriate values assigned to the static signals. Use the

generated HDL wrapper les in the design hierarchy by connecting the ports to the rest of the

design.

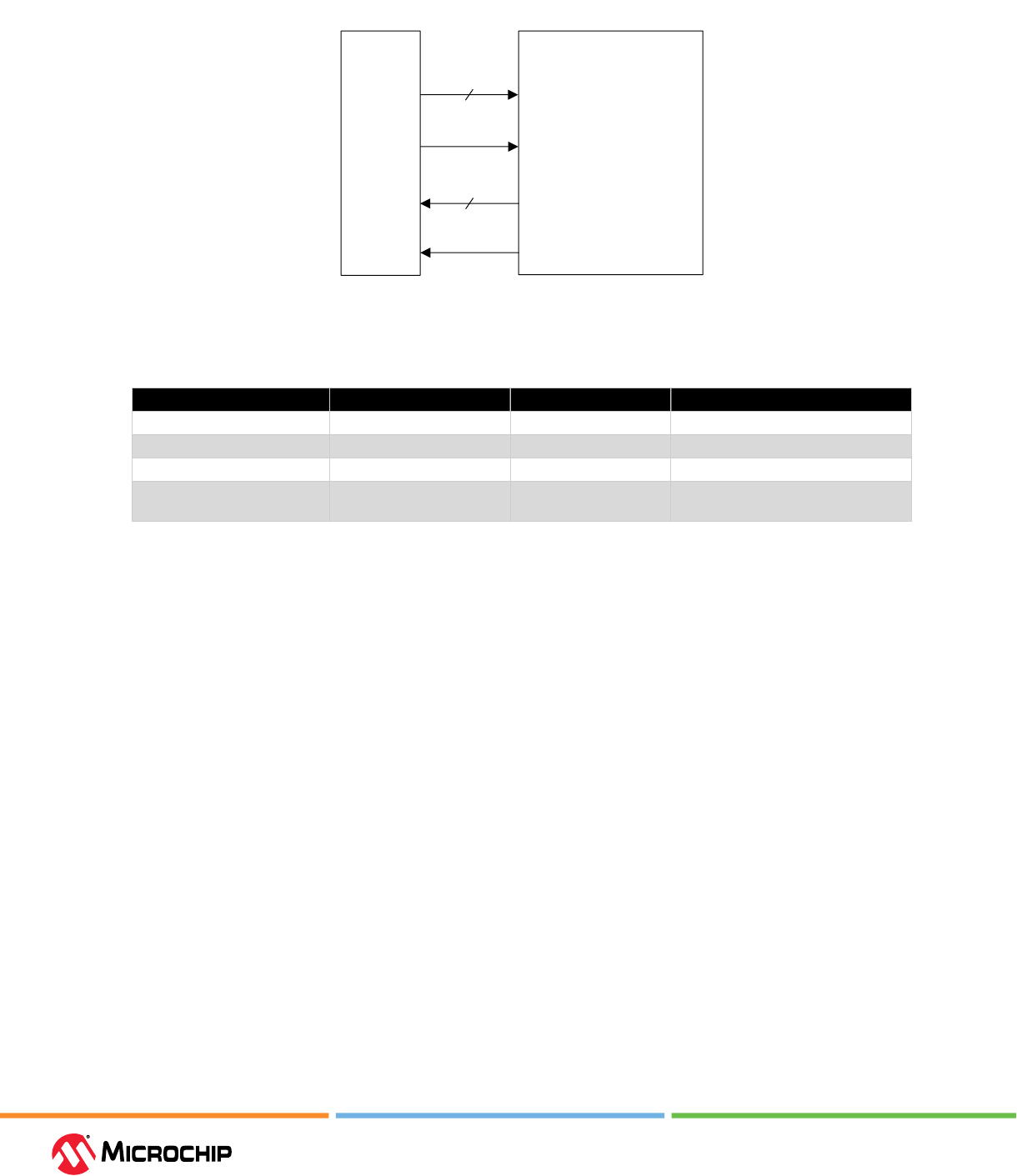

2.1.3.2.1 Dual-Port Large SRAM Congurator (Ask a Queson)

The PF_DPSRAM congurator is available in the Libero SoC IP Catalog > Memory & Controllers.

The PF_DPSRAM congurator automatically cascades LSRAM blocks to create wider and deeper

memories by selecting the most ecient aspect ratio. It also handles the grounding of unused

bits. The congurator supports the generation of memories that have dierent aspect ratios on

each port. The congurator uses one or more memory blocks to generate a RAM to match the

conguration. The congurator also creates an external logic required for the cascading.

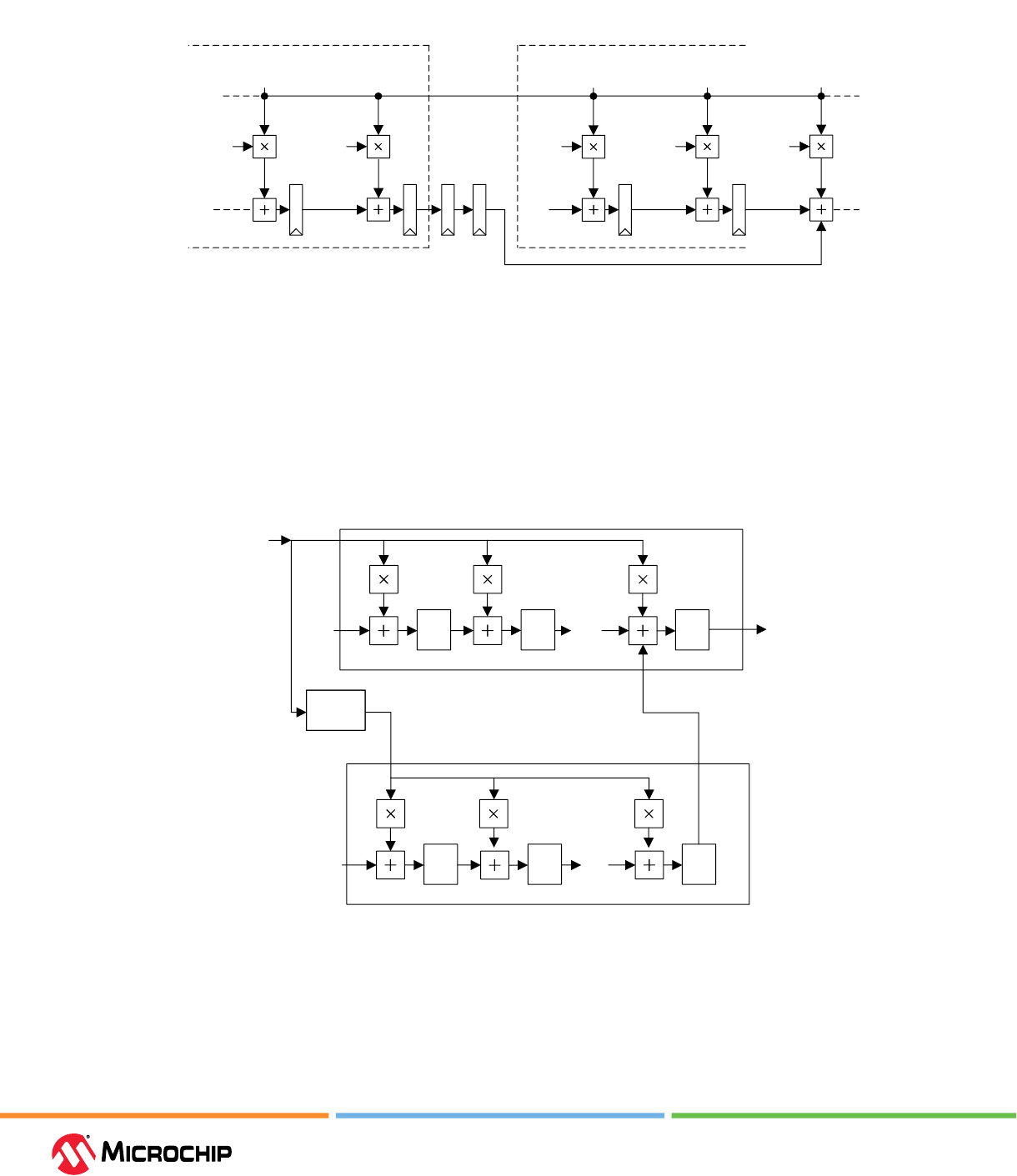

The congurator cascades RAM blocks in three dierent methods:

• Cascaded deep—For example, two blocks of 16384 x 1 are combined to create a 32768 x 1.

• Cascaded wide—For example, two blocks of 16384 x 1 are combined to create a 16384 x 2.

• Cascaded wide and deep—For example, four blocks of 16384 x 1 are combined to create a 32768

x 2, in a two-block width by two-block depth conguration.

For more information on Dual-Port mode, see 2.1.1. Dual-Port Mode.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 26

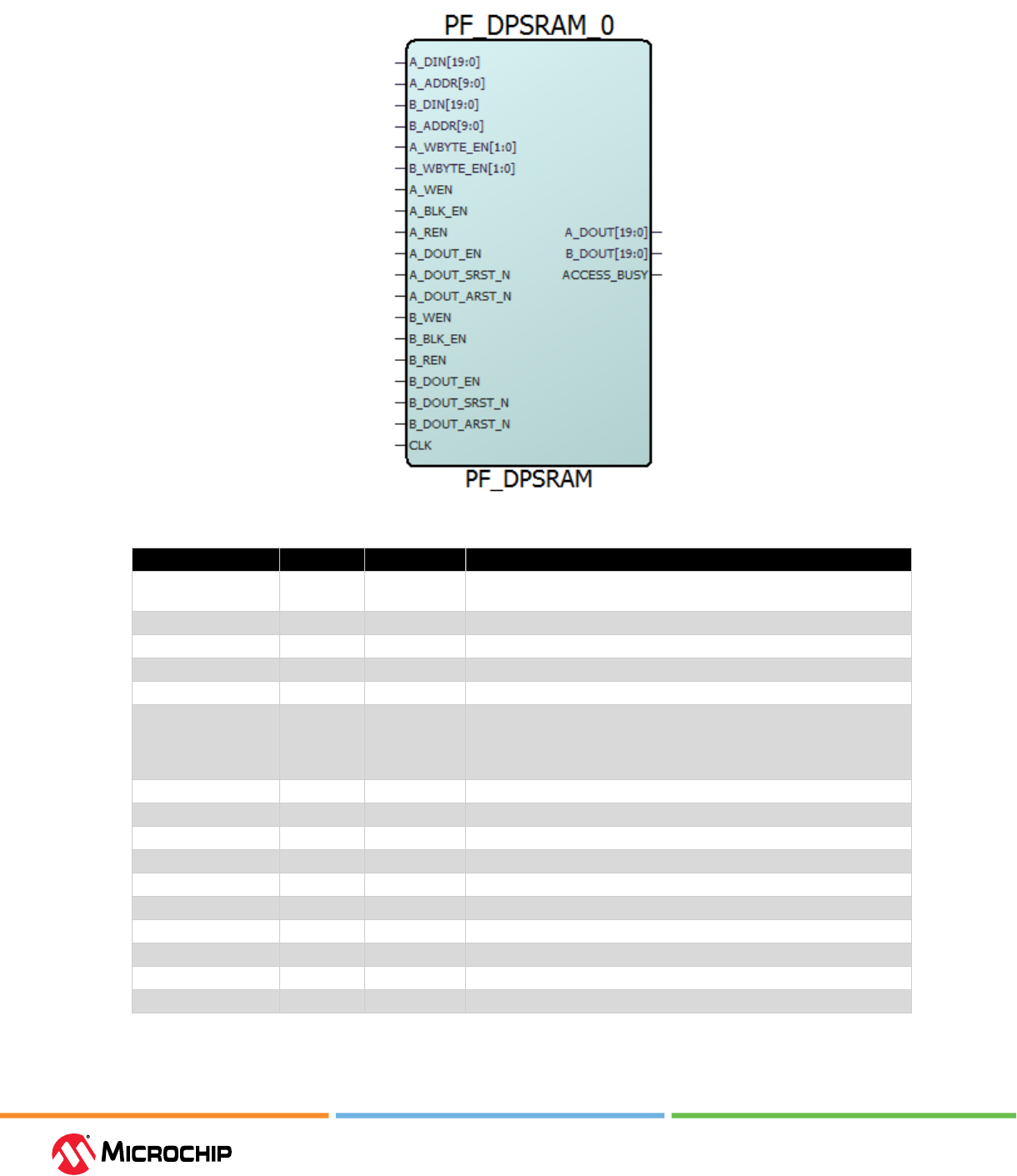

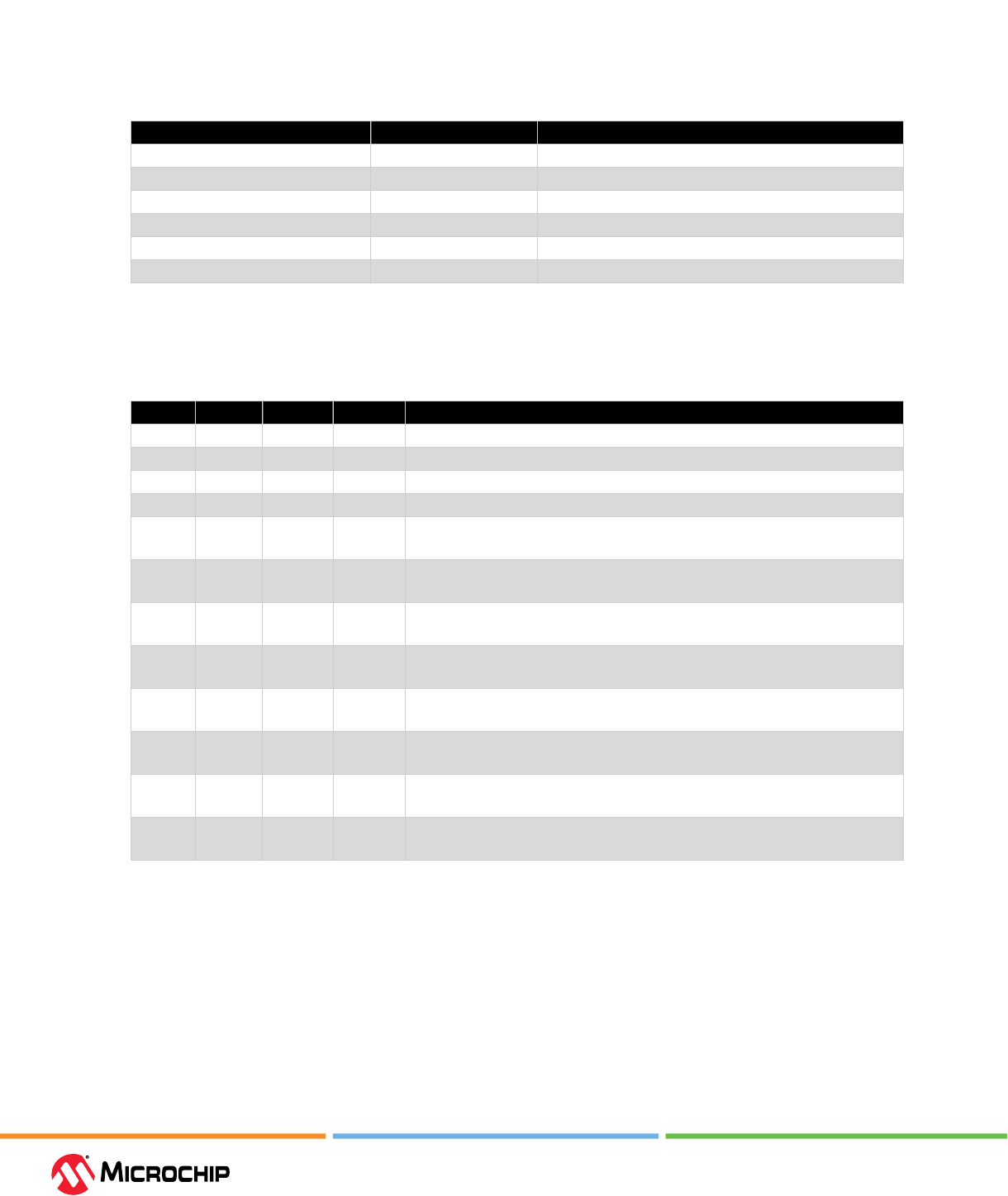

Figure 2-12. Dual-Port Large SRAM Congurator: Generated Component

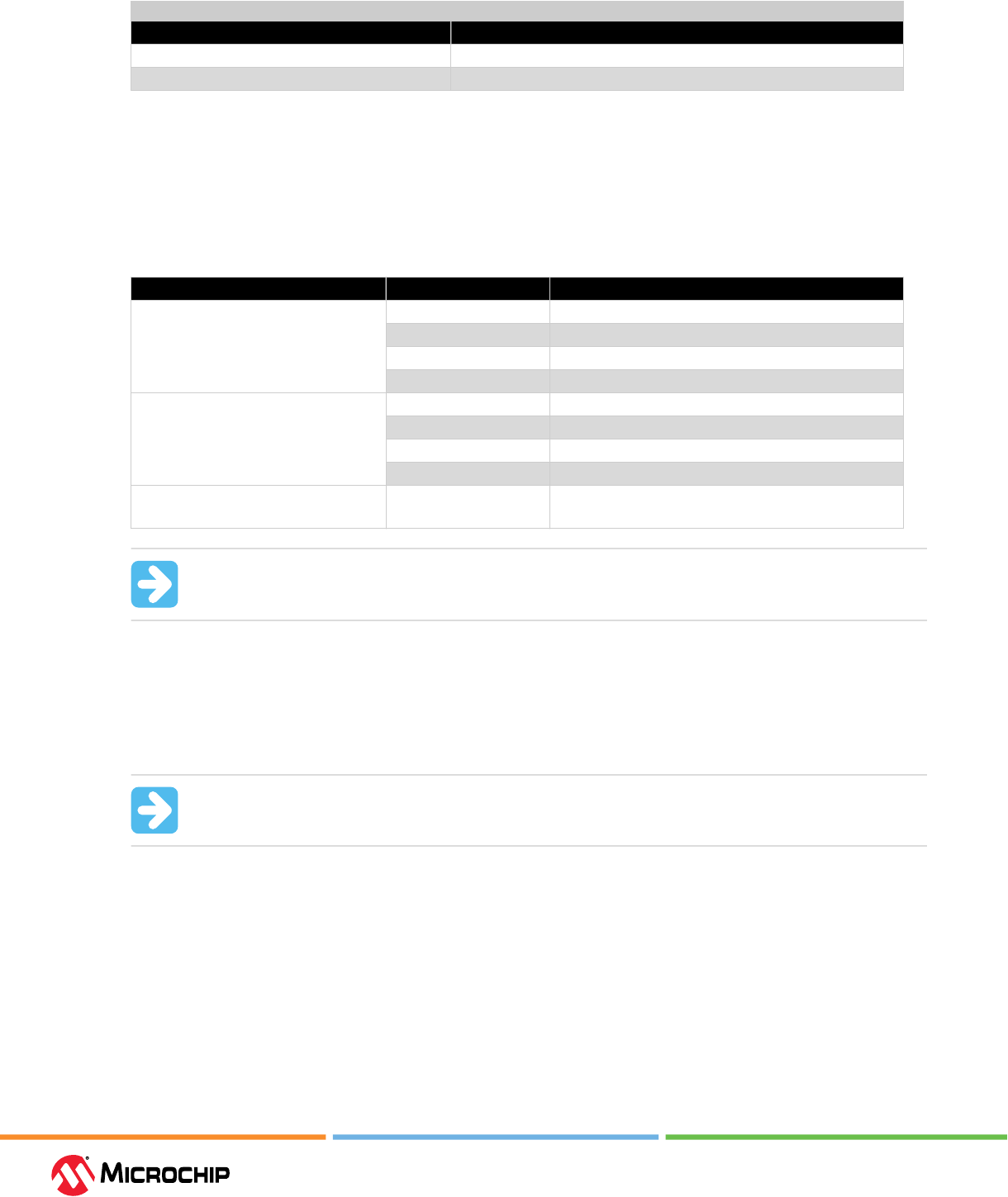

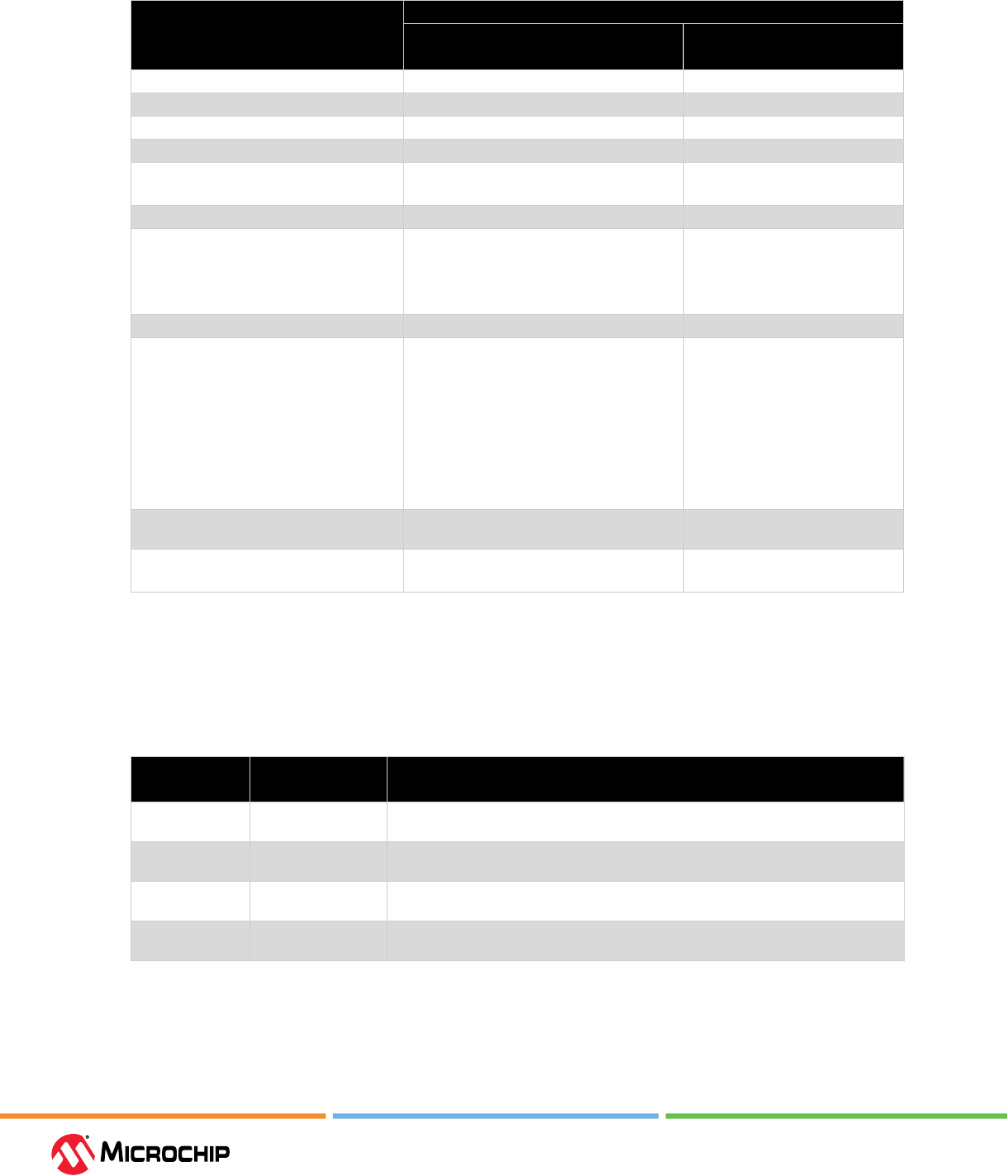

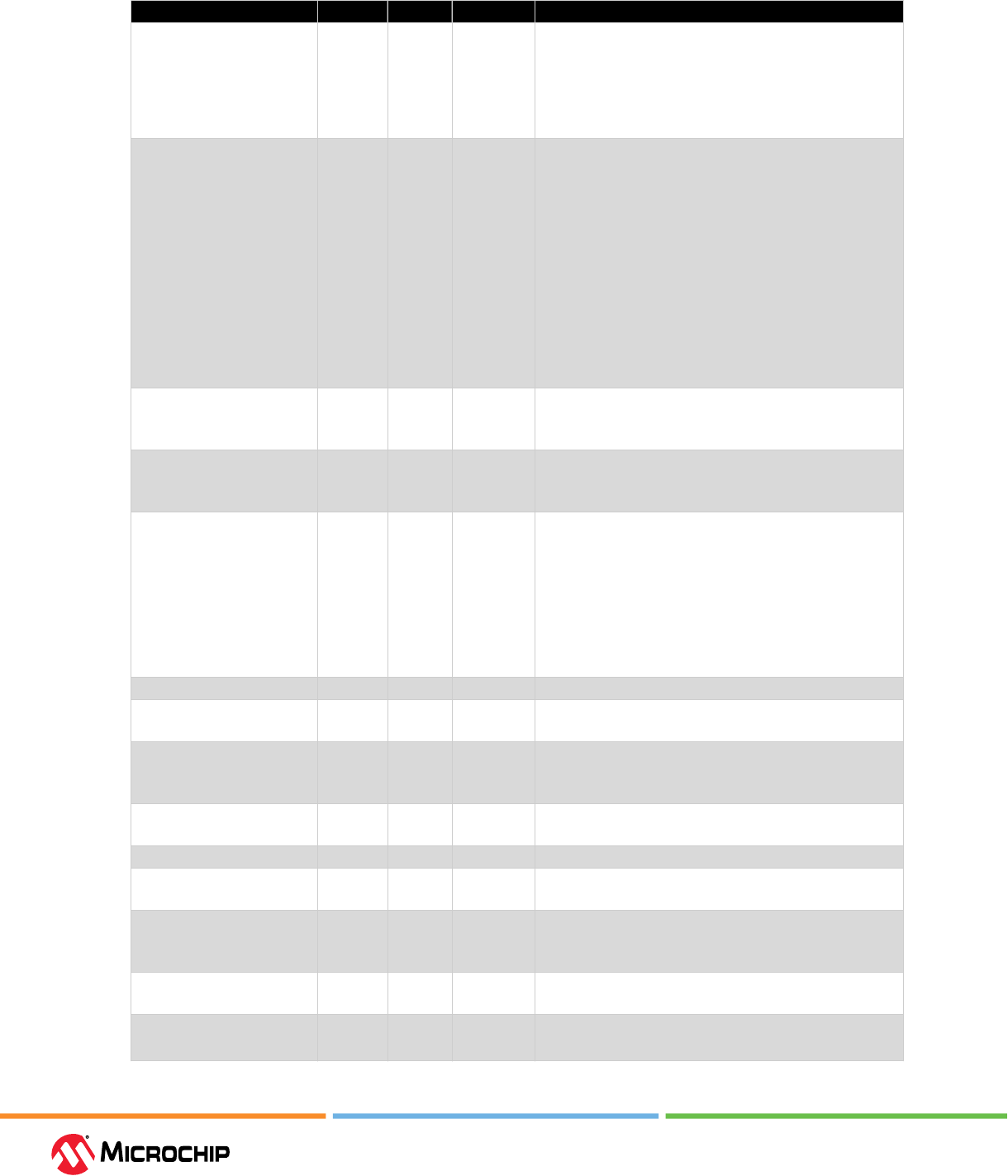

Table 2-9. Dual-Port LSRAM Congurator Signals

Port Direction Polarity Description

CLK Input Rising edge Single-clock signal that drives both ports with the same clock. Exposed

only when single clock is selected.

A_DIN[19:0] Input — Port A write data

A_ADDR[9:0] Input — Port A read address

A_BLK_EN Input Active High Port A block select

A_CLK Input Rising edge Port A clock. Applicable only when independent clocks are selected.

A_WEN Input — Port A signal to switch between write and read modes:

• Low: Read

• High: Write

A_REN Input — Port A read data enable

A_WBYTE_EN[1:0] Input — Port A write byte enable

A_DOUT[19:0] Output — Port A read data

A_DOUT_EN Input Active High Port A read data register enable

A_DOUT_SRST_N Input Active Low Port A read data register synchronous reset

A_DOUT_ARST_N Input Active Low Port A read data register asynchronous reset

B_DIN[19:0] Input — Port B write data

B_ADDR[9:0] Input — Port B address

B_BLK_EN Input Active High Port B enable

B_CLK Input Rising edge Port B clock. Applicable only when independent clocks are selected

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 27

...........continued

Port Direction Polarity Description

B_WEN Input — Port signal to switch between write and read modes:

• Low: Read

• High: Write

B_REN Input — Port B read data enable

B_WBYTE_EN[1:0] Input — Port B write byte enable

B_DOUT[19:0] Output — Port B read data

B_DOUT_EN Input Active High Port B read data register enable

B_DOUT_SRST_N Input Active Low Port B read data register synchronous reset

B_DOUT_ARST_N Input Active Low Port B read data register asynchronous reset

ACCESS_BUSY Output Active High Busy signal when being initialized or accessed using SmartDebug

The dual-port LSRAM congurator has three tabs:

• Parameter settings

• Port settings

• Memory initialization

Parameter Settings

The parameter settings include the optimization of LSRAM for High Speed or Low Power, clock signal

settings, and optional port settings. The following gure shows the Dual-Port Large LSRAM block

congurator.

Figure 2-13. Dual-Port Large SRAM Congurator: Parameter Sengs

Optimization for High Speed or Low Power

You can optimize the LSRAM with one of the following options:

• High Speed—Optimizes the LSRAM for speed and area by using width cascading.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 28

• Low Power—Optimizes the LSRAM for low power by using depth cascading, it uses additional

logic at the input and output.

Single Clock (CLK) or Independent Clocks (A_CLK and B_CLK)

You can set the clock signals and the signal polarity:

• Single clock—Drives both A and B ports with the same clock. This is the default conguration for

dual-port LSRAM.

• Independent clocks—Selects independent clock for each A_CLK for Port A and B_CLK for Port B).

• Rising edge or Falling edge—Changes the signal polarity.

Optional Ports

You can select one of the following optional ports:

• Lock access to SmartDebug—When enabled, SmartDebug access to the RAM is disabled.

• Expose ACCESS_BUSY output—When enabled, SmartDebug ACCESS_BUSY signal is available as

top-level port.

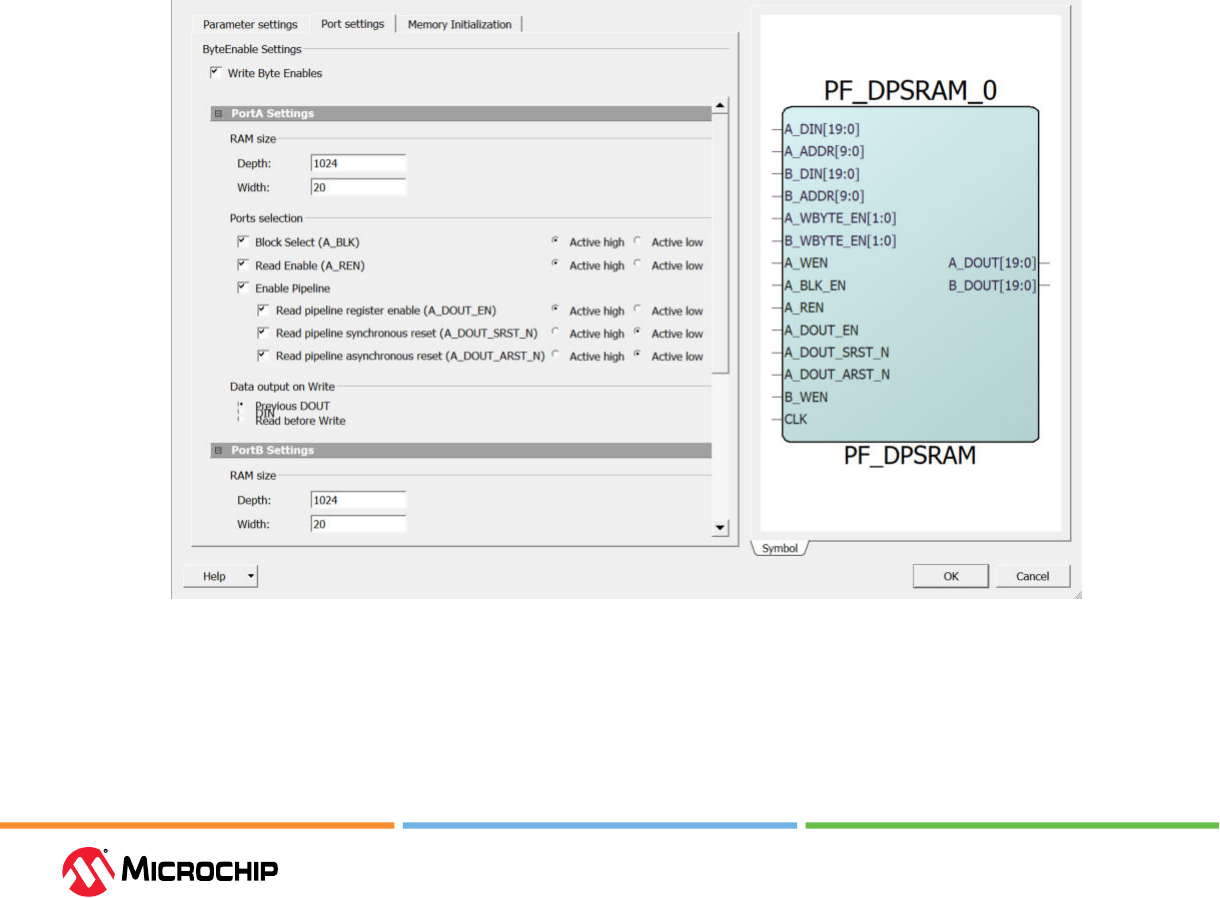

Port Settings

In the Port Settings tab, you can set the RAM size, select ports, and set data output on write settings

for both Ports A and B. The following gure shows the PF_DPSRAM block port settings.

Figure 2-14. Dual-Port Large SRAM Congurator: Port Sengs

Byte Enable Settings

Write Byte Enables—Enables writing to individual bytes of data (A_WBYTE_EN and B_WBYTE_EN).

The Write Byte Enable bits are all the control signals exposed by each column of LSRAM blocks when

the implementation splits the word width. The LSRAM congurator generates the most ecient

conguration of the depth and width for high-speed or low-power selection. Depending on the

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 29

generated conguration, each Write Byte Enable bit may control up to 10 bits of data. In other

words, the Write Byte Enable option does not govern the implementation.

In low-power mode for word widths that are multiples of 8, each Write Byte Enable bit controls 8 bits

unless the word width is also a multiple of 10. For example, generating a 32-bit word width LSRAM,

with Write Byte Enables, cascades the RAMs width-wise such that there are a total of 4 Write Byte

Enable bits (2 per RAM block) and each Write Byte Enable bit controls the writing of 8-bits of data.

Other Examples are as follows:

• Width of 17, is divided as 9 + 8.

• Width of 35, is rst divided as 18 + 17, and then, divided as 9 + 9 + 9 + 8.

RAM Size

You can set the RAM size.

• Depth—Sets the depth range. The depth range for each port is between 1 and 524288. The

maximum value depends on the die.

• Width—Sets the width range. The width range for each port is between 1 and 19040.

Important: The two ports can be congured independently for any depth and width.

However, Port A depth x Port A width must be equal to Port B depth x Port B width. The

width range varies between devices.

Ports Selection: Block Select (A_BLK_EN and B_BLK_EN)

The default conguration for A_BLK_EN and B_BLK_EN is unchecked, which ties the signal to the

Active state and removes it from the generated component. Select Active high or Active low to

change the signal polarity. Ports are populated on the component by checking the respective check

boxes.

Read Enable (A_REN and B_REN)

The default conguration for A_REN or B_REN is unchecked, which ties the signal to the active state

and removes it from the generated macro. Select Active high or Active low to change the signal

polarity. Ports are populated on the component by checking the respective check boxes.

Enable Pipeline

Check the Enable Pipeline check box to enable pipelining of read data (A_DOUT or B_DOUT).

If the Enable Pipeline check box is disabled, you cannot congure the A_DOUT_EN/B_DOUT_EN,

A_DOUT_SRST_N/B_DOUT_SRST_N, or A_DOUT_ARST_N/B_DOUT_ARST_N signals.

• Register Enable (A_DOUT_EN and B_DOUT_EN)—the pipeline registers for ports A and B have

active-high, enable inputs. By default, the check box is disabled. Selecting this check box adds the

signal to the top-level port.

• Synchronous Reset (A_DOUT_SRST_N and B_DOUT_SRST_N)—the pipeline registers for ports A

and B have active-low, synchronous reset inputs. By default, the check box is disabled. Selecting

this check box adds the signal to the top-level port.

• Asynchronous Reset (A_DOUT_ARST_N and B_DOUT_ARST_N)—the pipeline registers for ports

A and B have active-low, asynchronous reset inputs. By default, the check box is disabled.

Selecting this check box adds the signal to the top-level port.

Select Active high or Active low to change the signal polarity. Ports are populated on the

component by checking their respective check boxes.

Data Output on Write

Select the required option from the following:

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 30

• Previous DOUT—The default data on the Read data output (A_DOUT or B_DOUT) during a write

cycle is the DOUT data from the previous cycle (Previous DOUT).

• DIN—To enable feed-through write mode on Read data output.

• Read before Write—To perform a read operation before a write operation overwriting the

previous data.

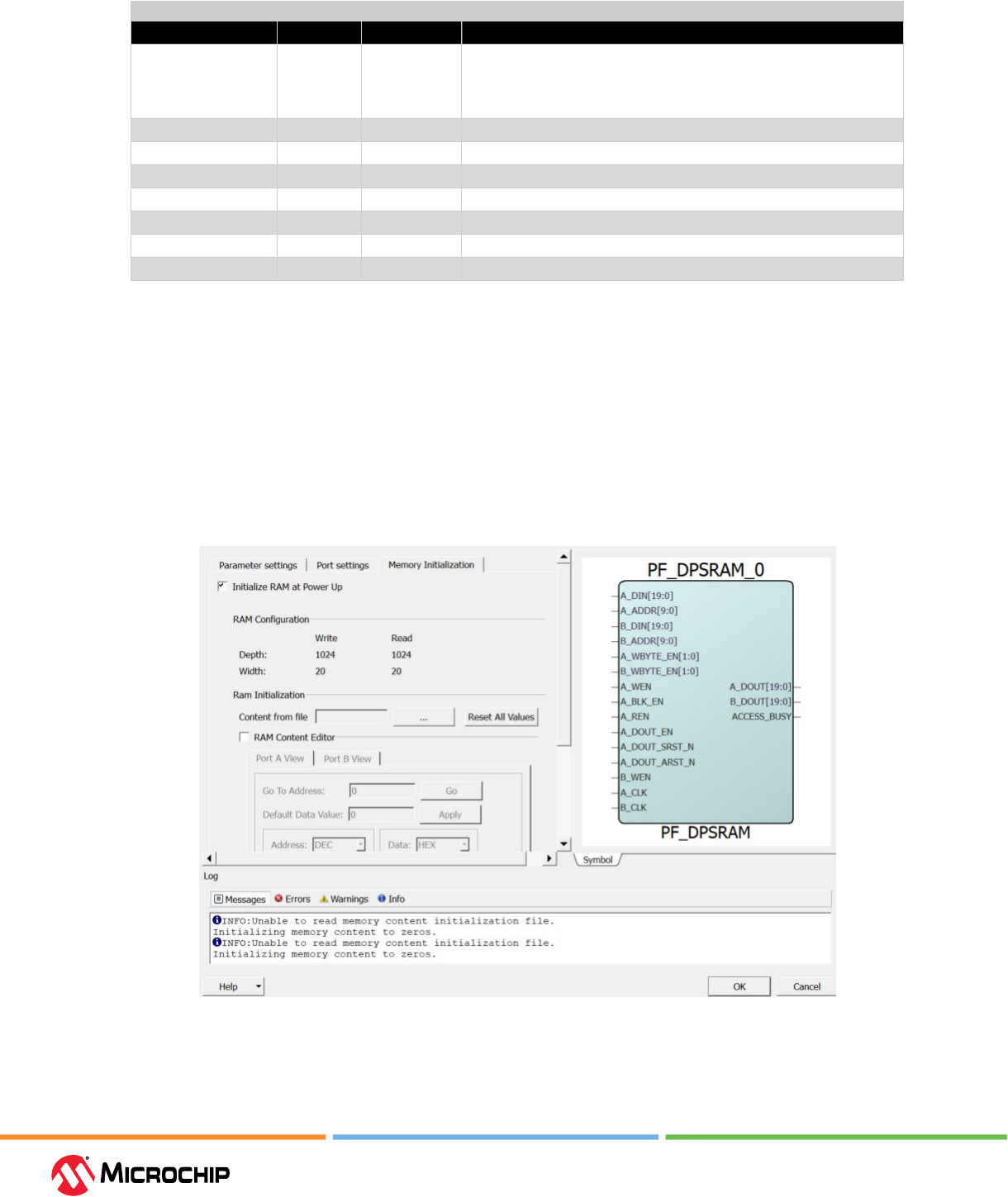

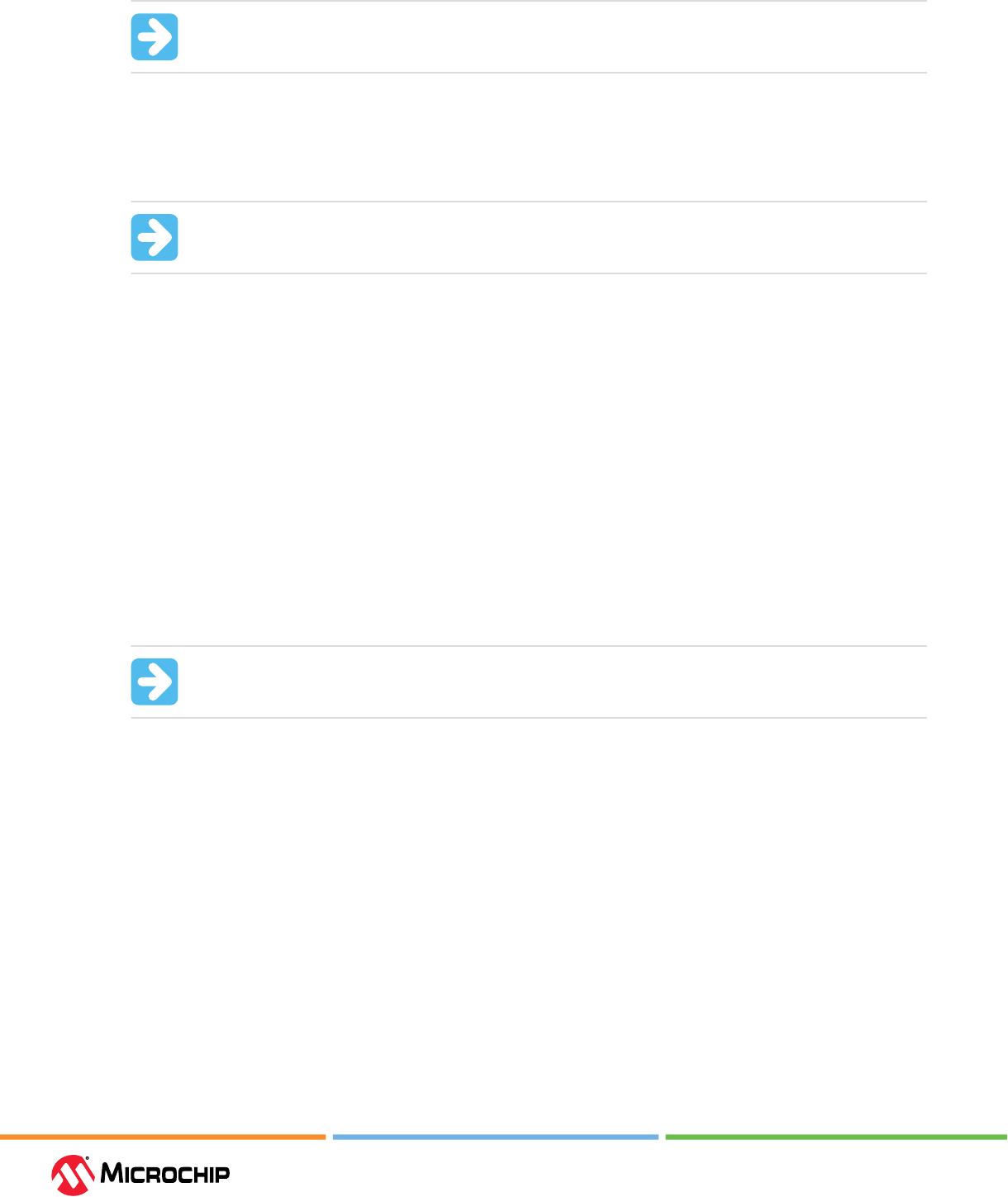

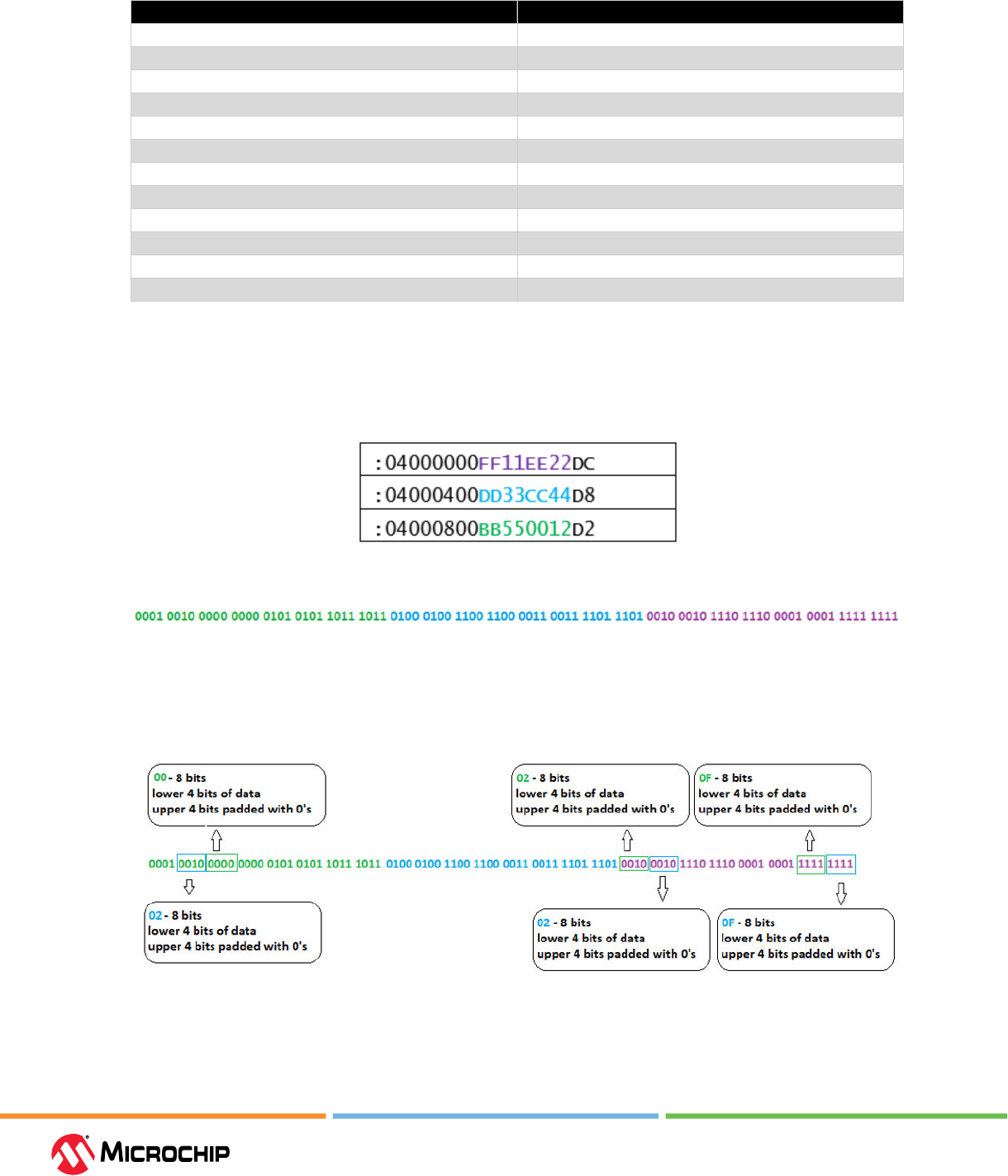

Memory Initialization at Power-Up

In the Memory Initialization tab, you can initialize RAM at power-up. LSRAM can be initialized

during device power-up and functional simulation. The following gure shows the PF Dual Port Large

SRAM IP memory initialization.

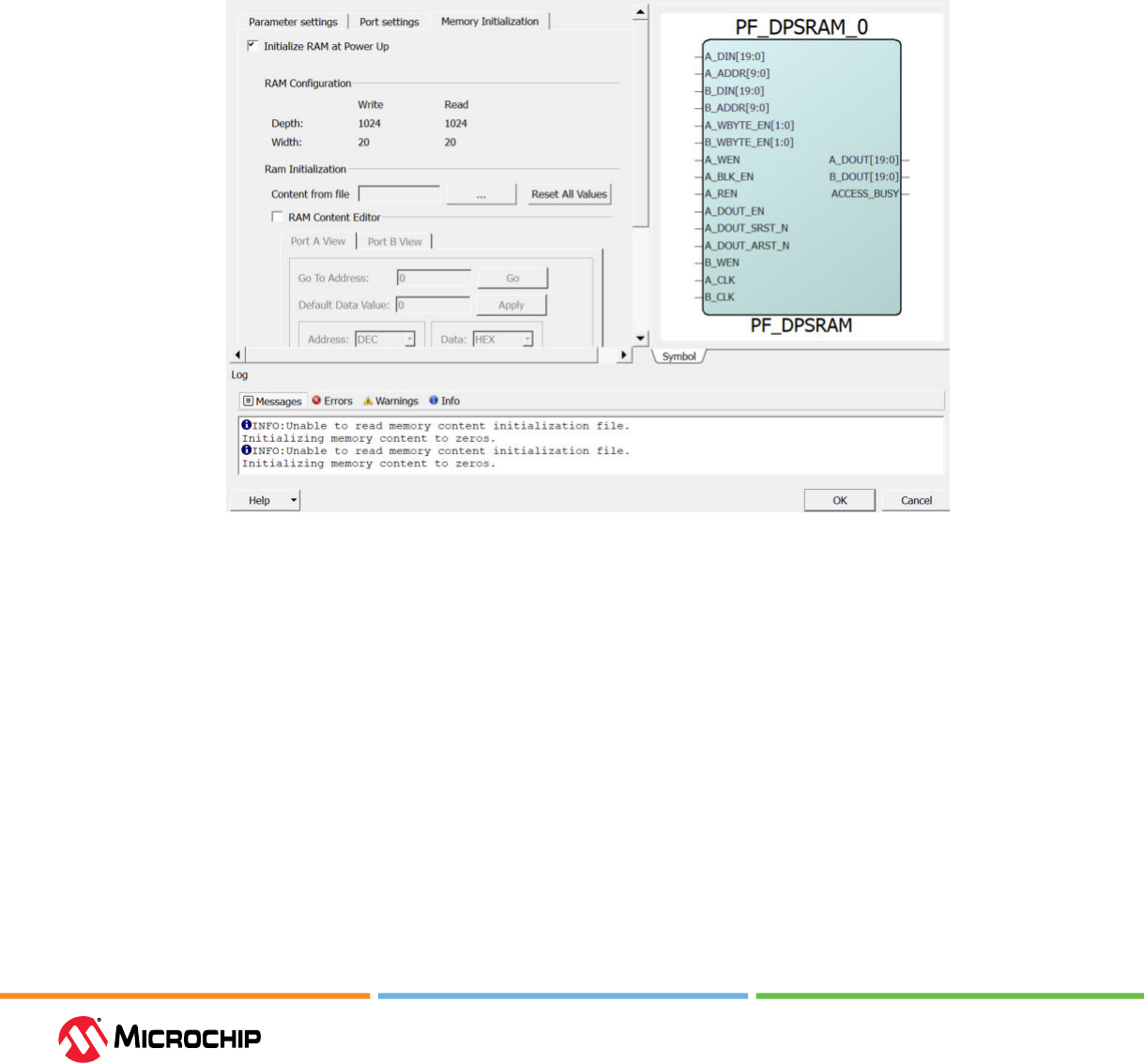

Figure 2-15. Dual-Port Large SRAM Congurator: Memory Inializaon

Initialize RAM at Power Up

You can initialize RAM during power-up of the device by setting the following:

• Initialize RAM at Power Up—Loads the RAM content during device operation at power-up and

functional simulation.

• RAM Conguration—Both write and read depths and widths are displayed as specied in the

Port settings tab.

• Initialize RAM Contents From File—The RAM’s content can be initialized by importing the

memory le. This avoids the simulation cycles required for initializing the memory and reduces

the simulation runtime. The congurator partitions the memory le appropriately so that the

right content goes to the right block RAM when multiple blocks are cascaded.

• Import File—Selects and imports a memory content le (Intel-Hex) from the Import Memory

Content dialog box. File extensions are set to *.hex for Intel-Hex les during import. For more

information, see 4. Appendix: Supported Memory File Formats for LSRAM and μSRAM. The

imported memory content is displayed in the RAM Content Editor.

• Reset All Values—Resets all the data values. This option is enabled when the RAM Content

Editor check box is selected.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 31

RAM Content Editor

The RAM Content Editor enables the user to specify the contents of RAM memory manually for both

Port A and Port B. It also allows you to modify imported data.

Port A View/Port B View

• Go To Address—Enables you to go to a specic address in the editor. You can select the number

display format (HEX, BIN, and DEC) from the Address menu.

• Default Data Value—You can set this with new data to change the default. When the data value

is changed, all default values in the manager are updated to match the new value. You can select

the number display format (HEX, BIN, and DEC) from the Data menu.

• Address—The Address column lists the address of a memory location. The menu species the

number format of the address list (hexadecimal, binary, or decimal).

• Data—Controls the data format and data values in the manager.

Click OK to close the manager and save all changes made to the memory and its contents. Click

Cancel to close the manager and cancel all the changes.

Important: The dialogs show all data with the MSb down to LSb. For example, if the row

showed 0xAABB for a 16-bit word size, the AA is MSb and BB is LSb.

2.1.3.2.2 Two-Port LSRAM Congurator (Ask a Queson)

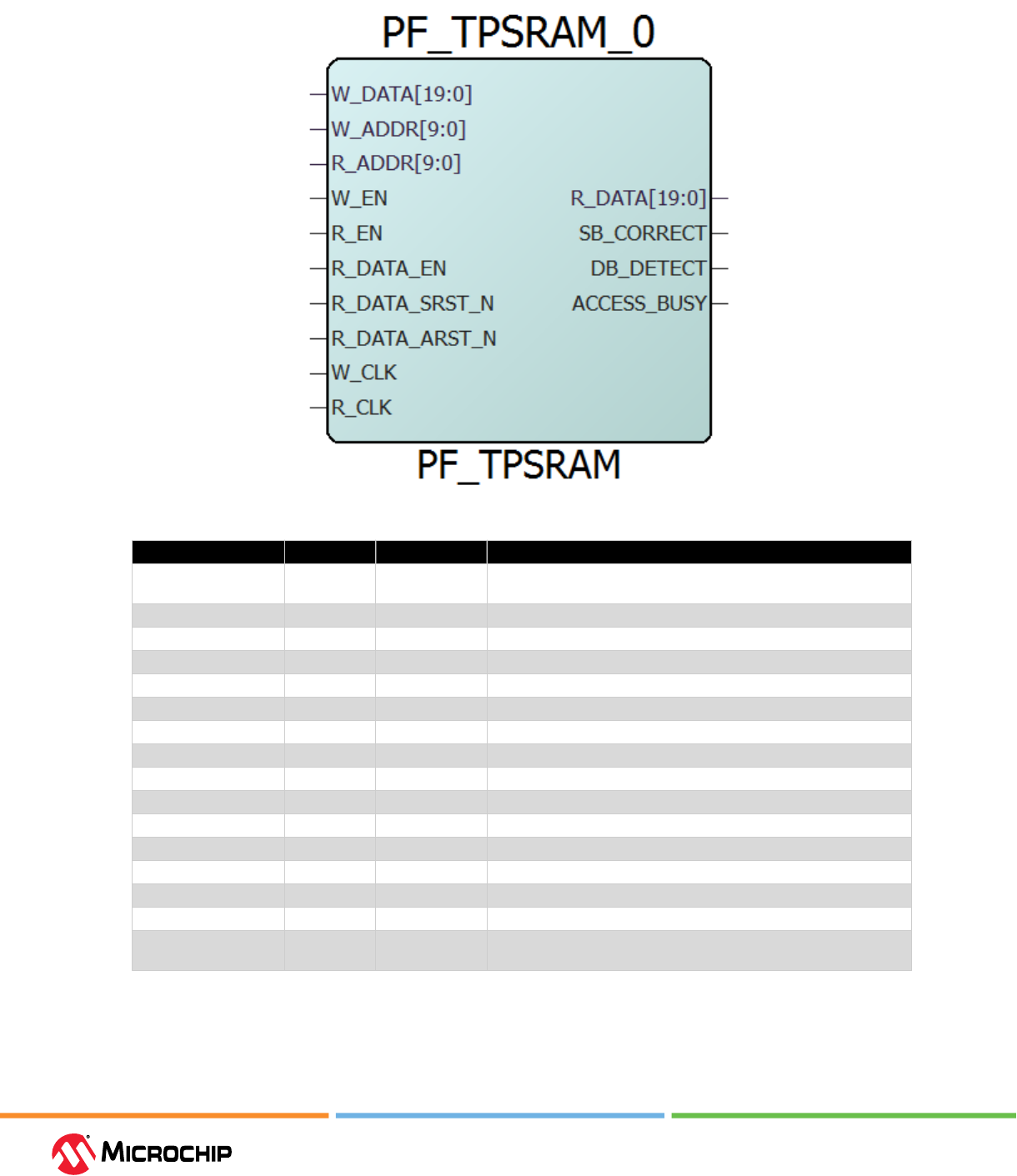

The Two-Port SRAM (TPSRAM) IP congurator is available in the Libero SoC software under Memory

& Controllers. The following gure shows the TPSRAM IP block available in the Libero SoC software.

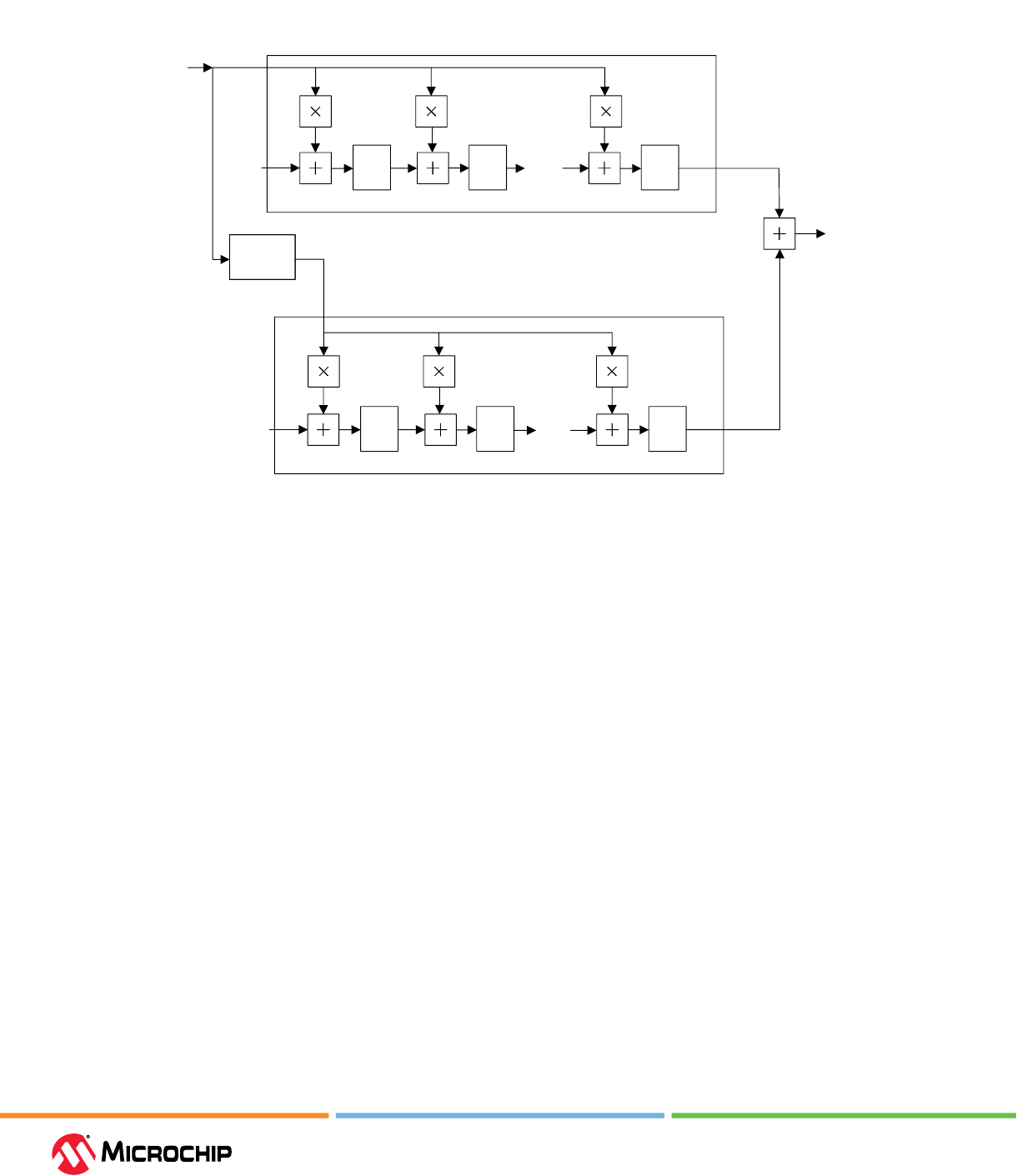

The TPSRAM congurator enables write access on one port and read access on the other port. The

RAM congurator automatically cascades LSRAM blocks to create wider and deeper memories by

selecting the most ecient aspect ratio. It also handles the grounding of unused bits. The core

congurator supports the generation of memories that have dierent write and read aspect ratios.

The congurator uses one or more memory blocks to generate a RAM matching the conguration. In

addition, it also creates the surrounding cascading logic.

The congurator cascades RAM blocks in three dierent methods:

• Cascaded deep—For example, two blocks of 16384 x 1 combined to create a 32768 x 1.

• Cascaded wide—For example, two blocks of 16384 x 1 combined to create a 16384 x 2.

• Cascaded wide and deep—For example, four blocks of 16384 x 1 combined to create a 32768 x 2,

in two blocks width-wise by two blocks depth-wise conguration.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 32

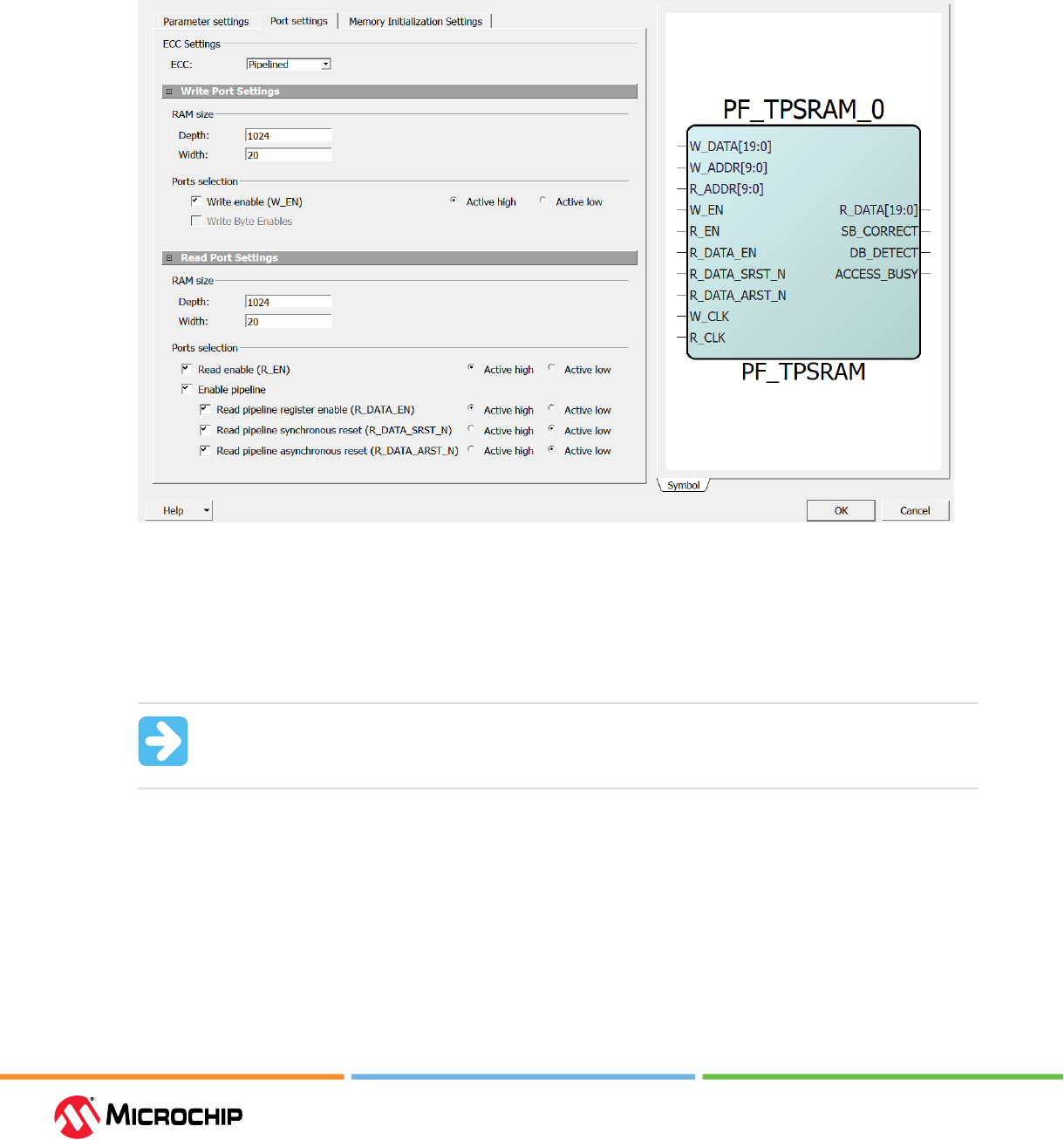

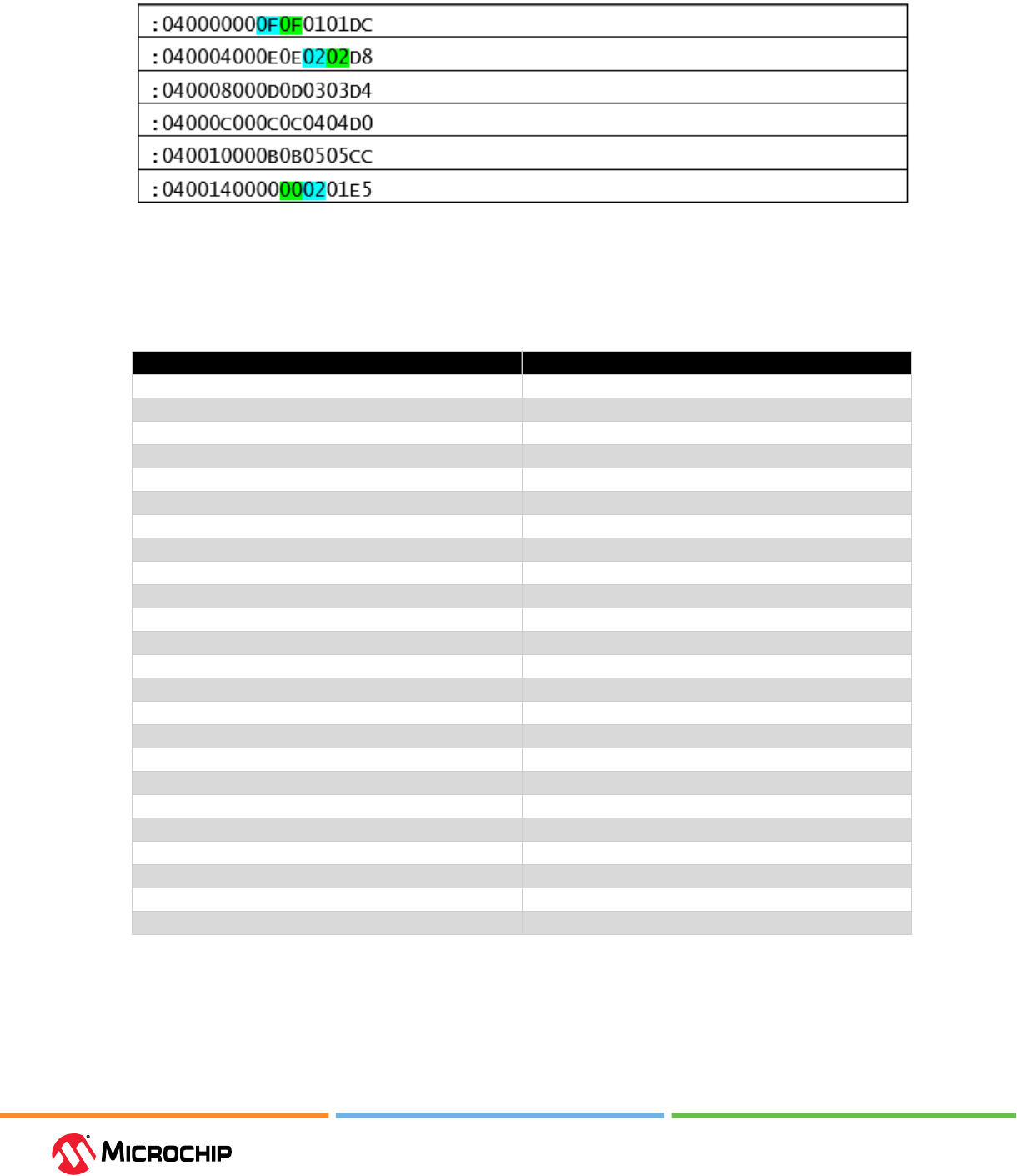

Figure 2-16. Two-Port Large SRAM Congurator with ECC Enabled

Table 2-10. Two-Port Large SRAM Congurator Signals

Port Direction Polarity Description

CLK Input Rising edge Single clock to drive both W_CLK and R_CLK. Applicable only when

single read/write clock is selected.

W_DATA[19:0] Input — Write data

W_ADDR[9:0] Input — Write address

W_EN Input Active High Write port enable

W_CLK Input Rising edge Write clock. Applicable only when independent clocks are selected.

R_CLK Input Rising edge Read clock. Applicable only when independent clocks are selected.

R_EN Input Active High Read data enable.

WBYTE_EN[] Input — Write enable for byte write.

R_ADDR[9:0] Input — Read address

R_DATA[19:0] Output — Read data

R_DATA_EN Input Active High Read data register enable

R_DATA_SRST_N Input Active Low Read data register synchronous reset

R_DATA_ARST_N Input Active Low Read data register asynchronous reset

SB_CORRECT Output Active High Single-bit correct ag. Applicable only when ECC is enabled.

DB_DETECT Output Active High Double-bit detect ag. Applicable only when ECC is enabled.

ACCESS_BUSY Output Active High Busy signal from SmartDebug. Exposed only when Expose

ACCESS_BUSY output is checked.

The Two-Port LSRAM congurator has three tabs:

• Parameter settings

• Port settings

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 33

• Memory initialization settings

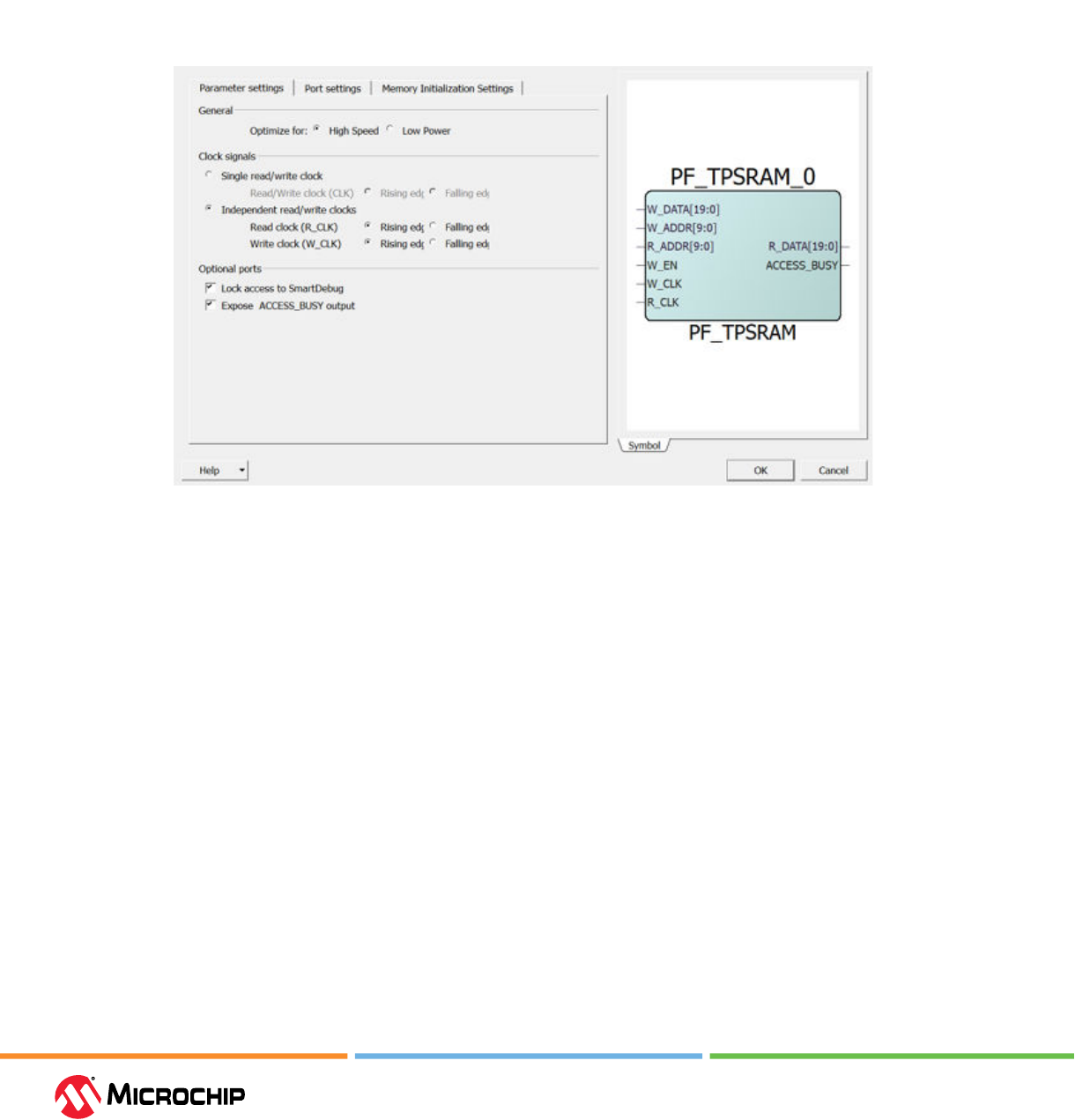

Parameter Settings

The parameter settings include the Optimization for High Speed or Low Power, clock signals settings,

and optional port settings. The following gure shows the TPSRAM block congurator.

Figure 2-17. Two-Port Large SRAM Congurator: Parameter Sengs

Optimization for High Speed or Low Power

You can optimize the LSRAM macro with one of the following options:

• High Speed—Optimizes the LSRAM macro for speed and area by using width cascading.

• Low Power—Optimizes the LSRAM macro for low power, but it uses additional logic at the input

and output by using depth cascading.

Single Read/Write Clock (CLK) or Independent Read/Write Clocks

You can set the clock signals and the signal polarity as follows:

• Single clock—Drives write and read with the same clock. This is the default conguration for

Two-Port LSRAM.

• Independent clocks—Selects independent clock for Read (R_CLK) and Write (W_CLK)—R_CLK

and W_CLK.

• Rising edge or Falling edge—Sets the signal polarity.

Optional Ports

The user can select one of the following optional ports:

• Lock access to SmartDebug—When enabled, SmartDebug access to the RAM is disabled.

• Expose ACCESS_BUSY output—When enabled, SmartDebug ACCESS_BUSY signal is available as

top-level port.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

DS60001725G - 34

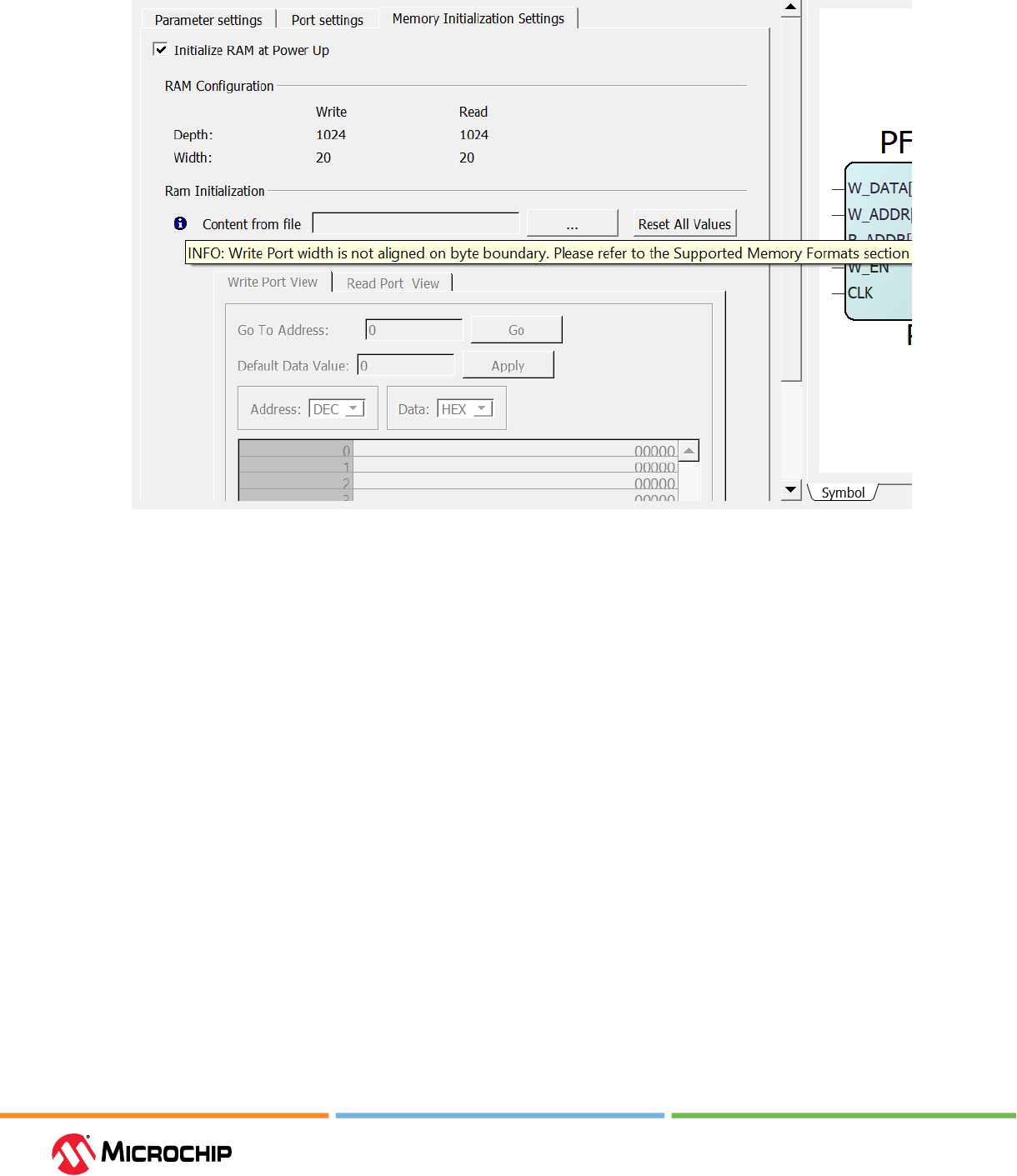

Port Settings

In the Port Settings tab, the user can set RAM size, select ports, and set data output on write

settings for both ports. The following gure shows the TPSRAM block port settings.

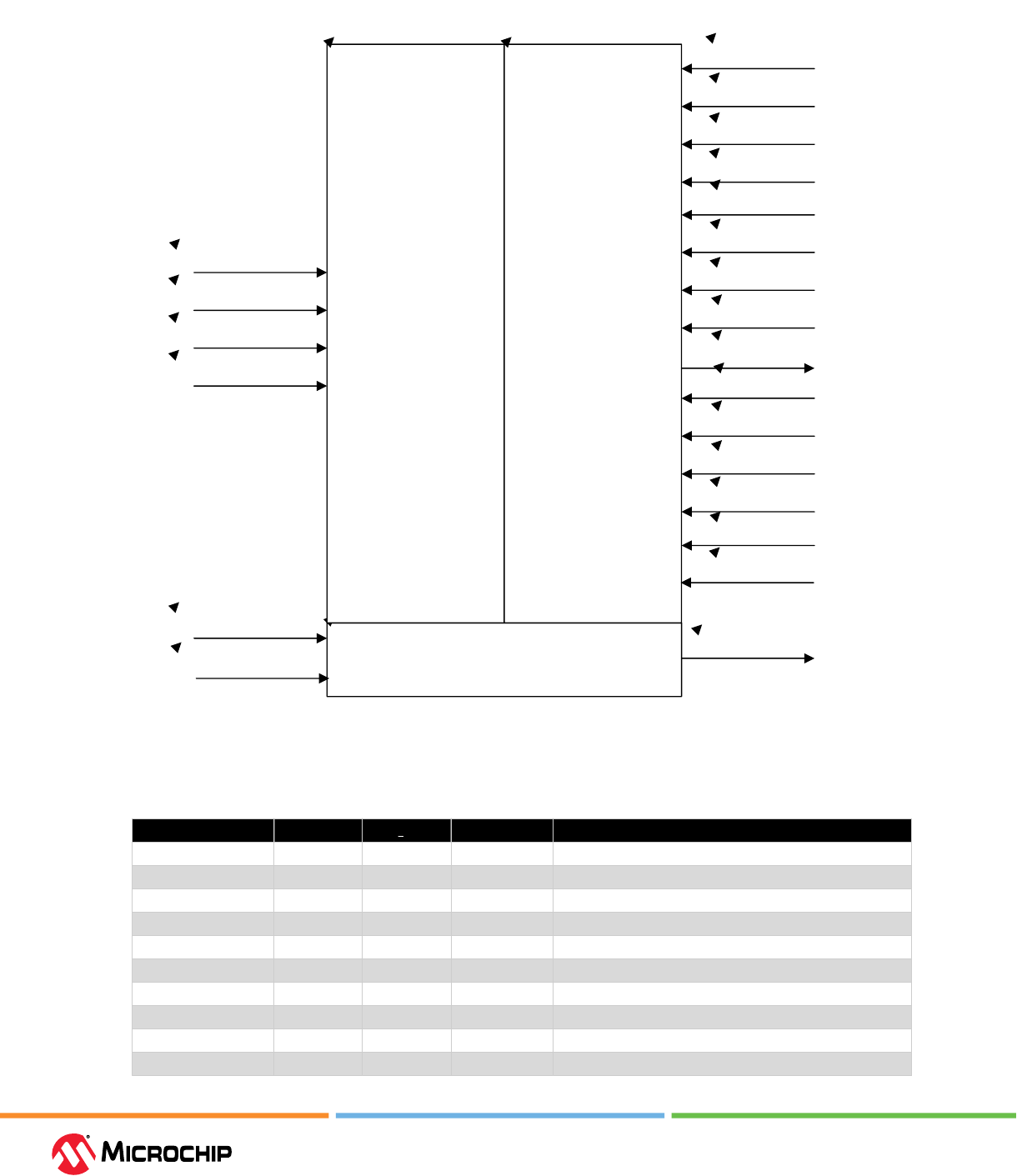

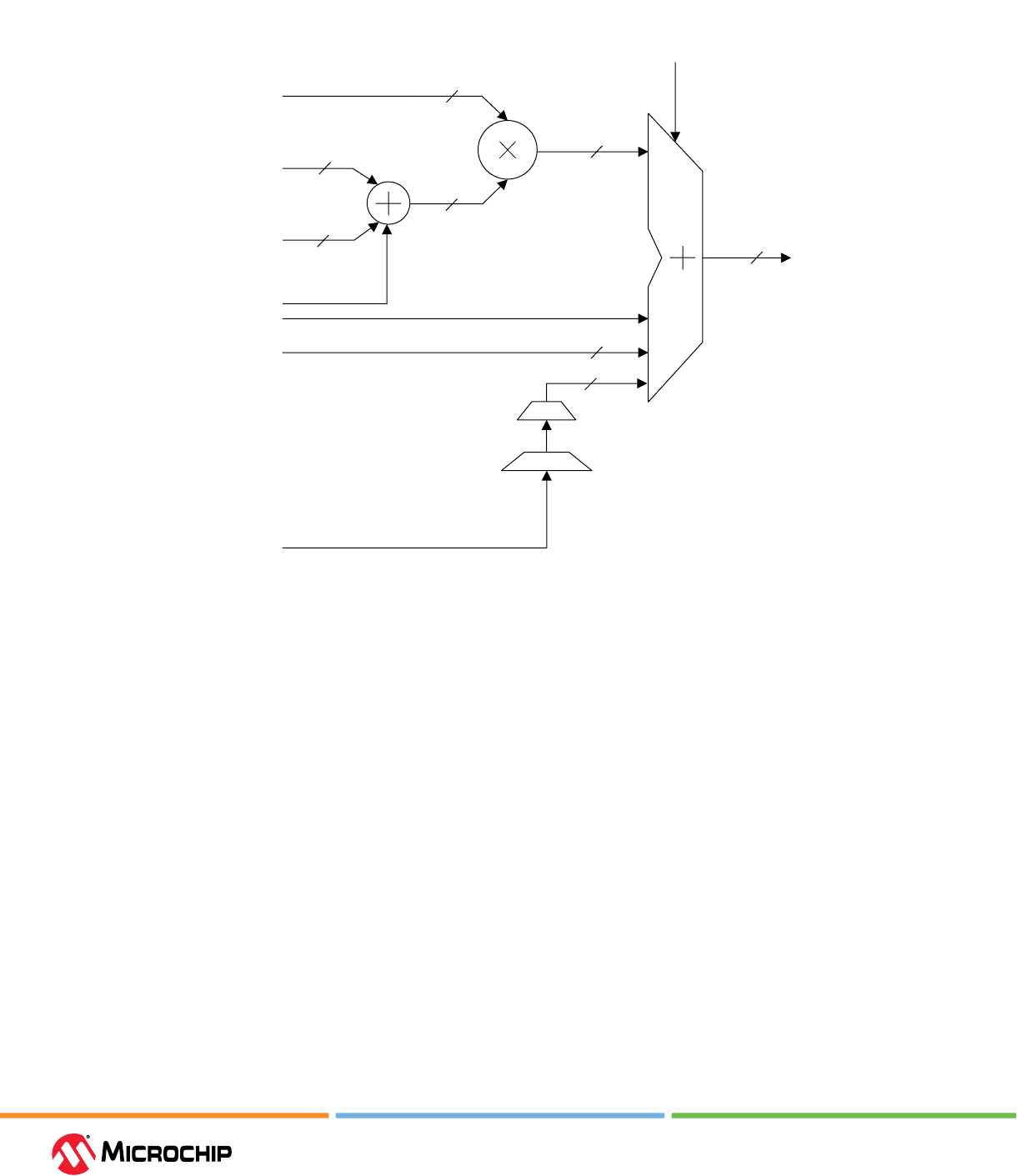

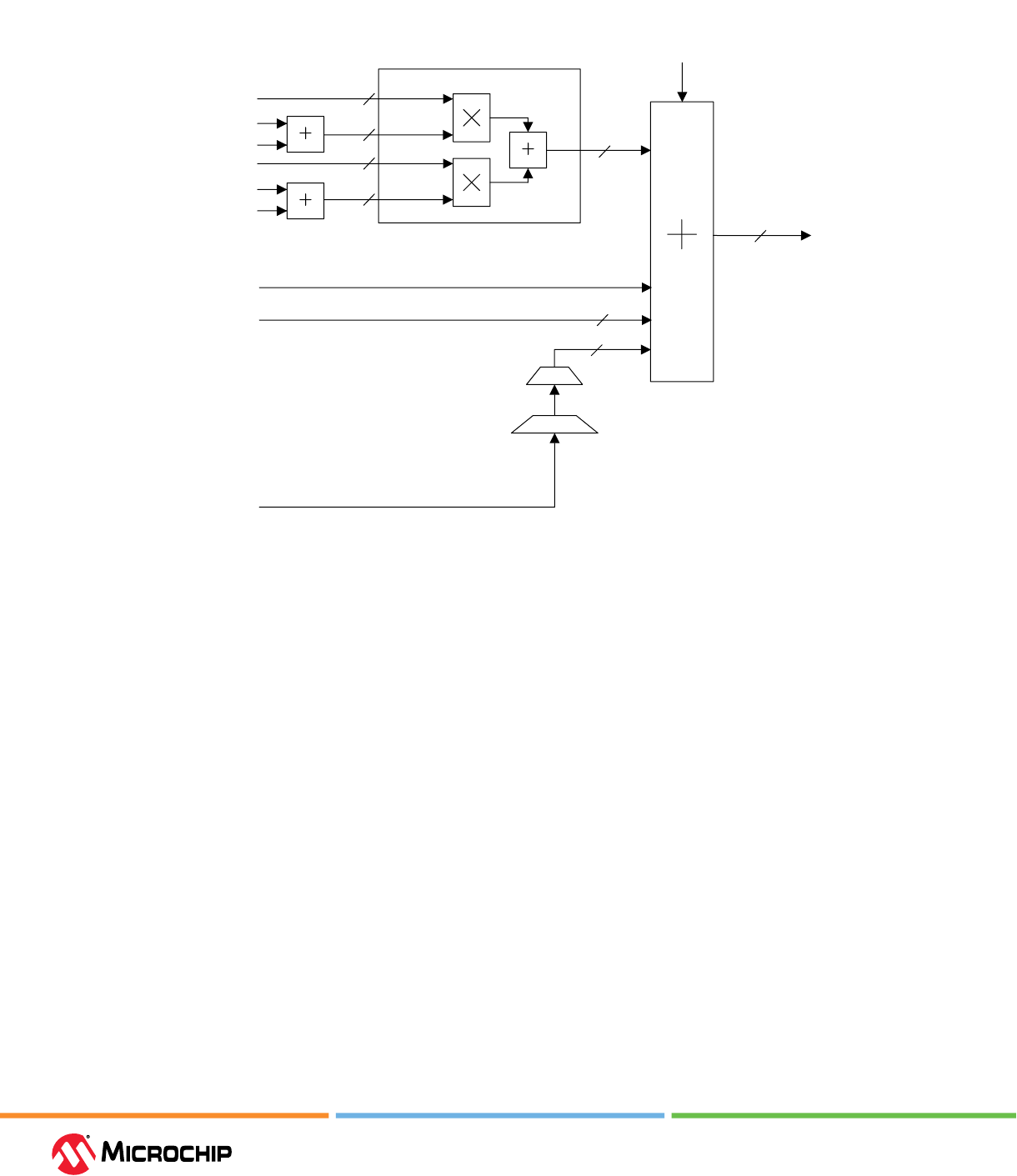

Figure 2-18. Two-Port Large SRAM Congurator: Port Sengs

ECC

The following three Error Correction Code (ECC) options are available:

• Disabled

• Pipelined

• Non-pipelined

Important: When ECC is enabled (pipelined or non-pipelined), both ports have data

widths equal to 33 bits. The SB_CORRECT and DB_DETECT output ports are exposed when

ECC is enabled.

Write Byte Enable Settings

Write Byte Enables—Enables the writing of individual bytes of data (WBYTE_EN). This port is

disabled while the ECC is enabled.

The Write Byte Enable bits are all the control signals exposed by each column of LSRAM blocks when

the implementation splits the word width. The LSRAM congurator generates the most ecient

conguration of the depth and width for high-speed or low-power selection. Depending on the

generated conguration, each Write Byte Enable bit may control up to 10 bits of data. In other

words, the Write Byte Enable option does not govern the implementation.

Embedded Memory Blocks

User Guide

© 2023 Microchip Technology Inc. and its subsidiaries

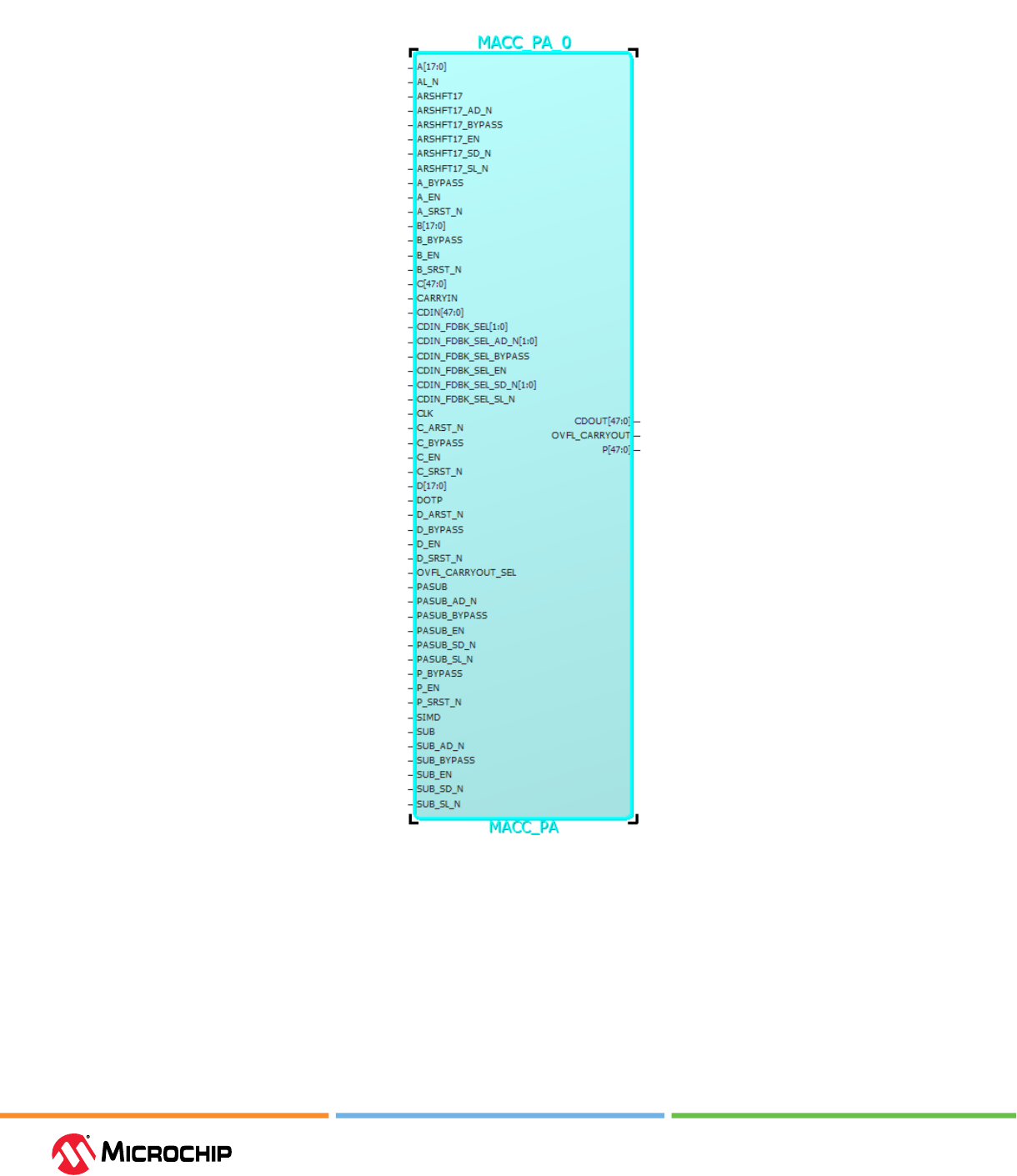

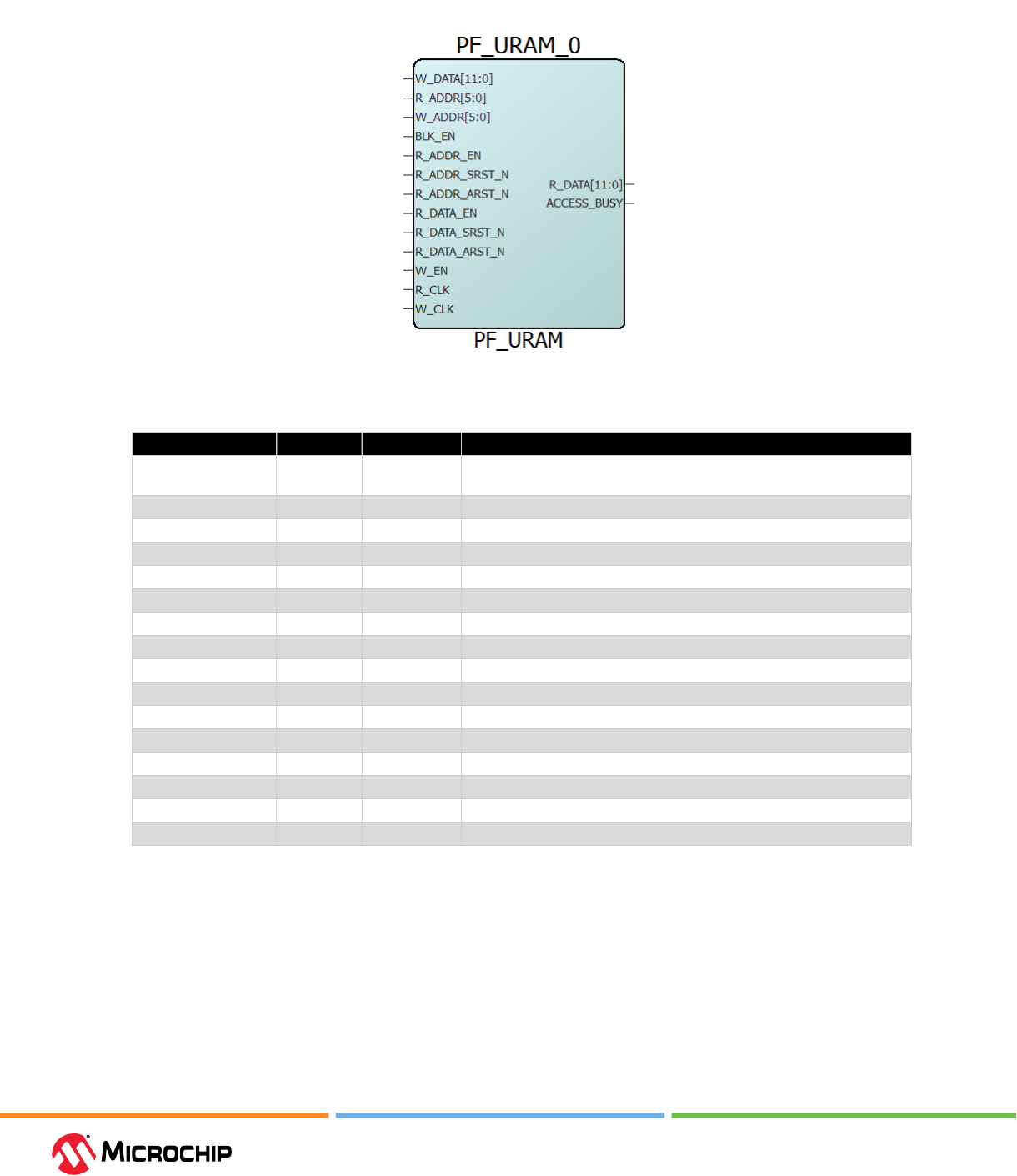

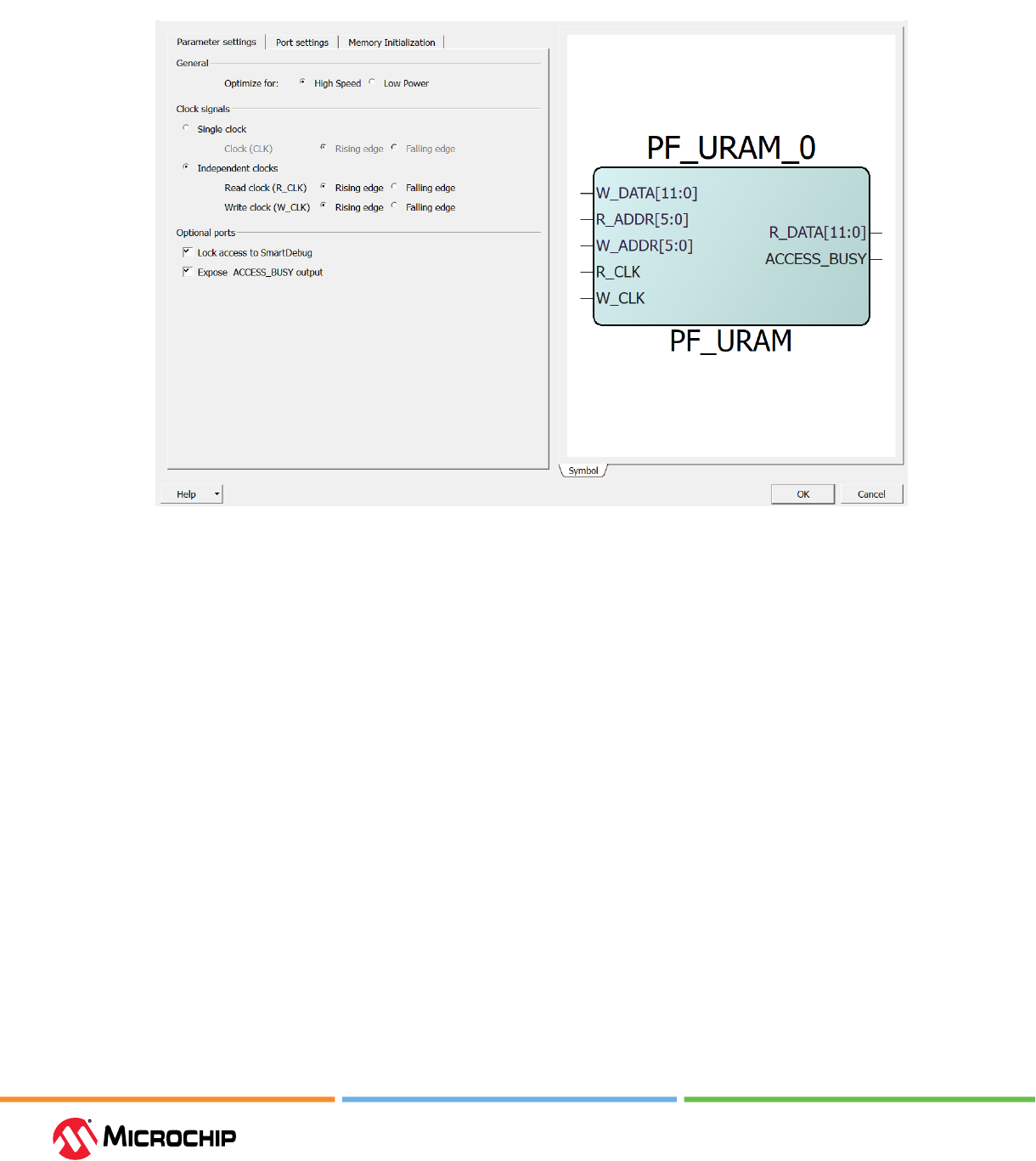

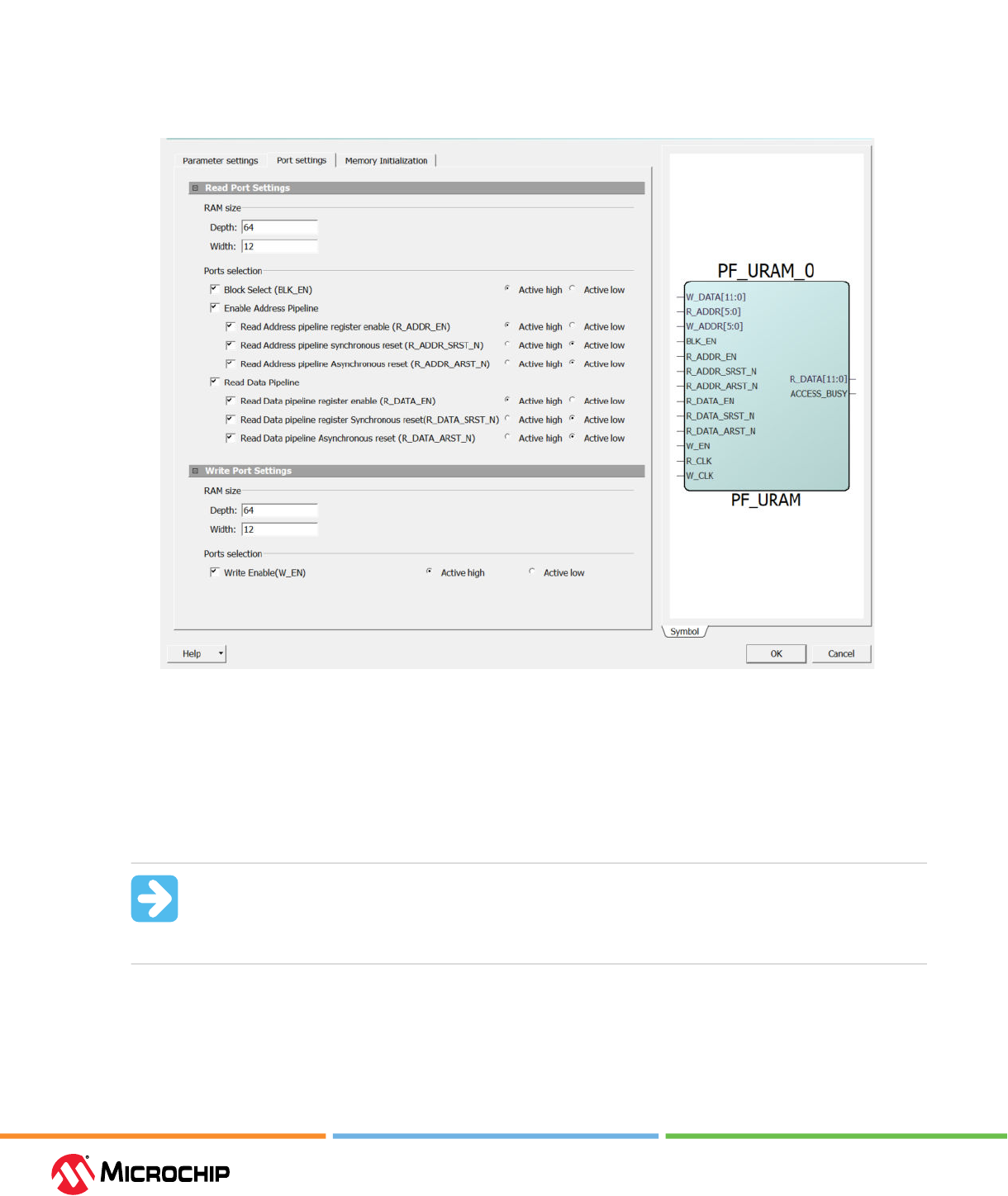

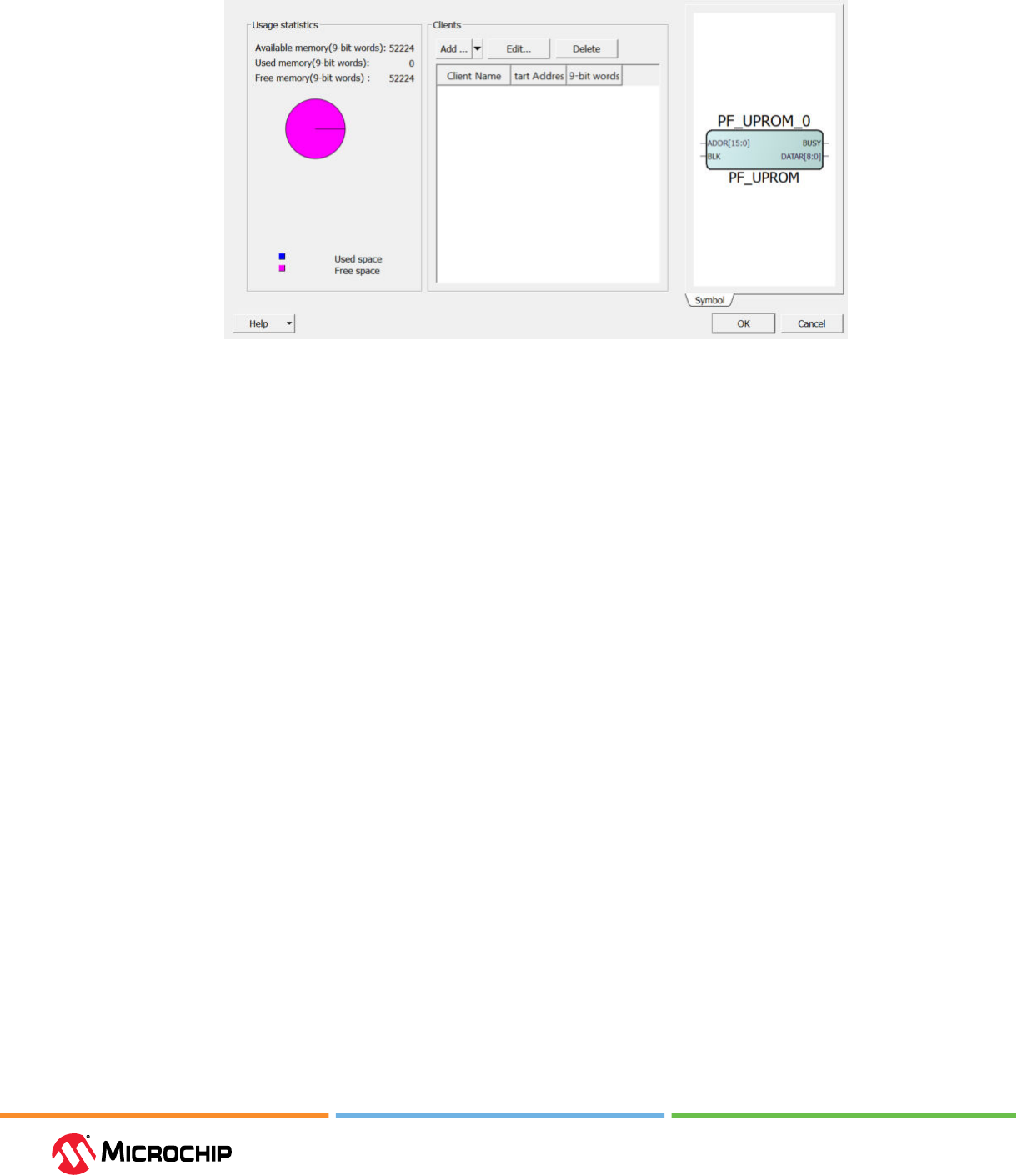

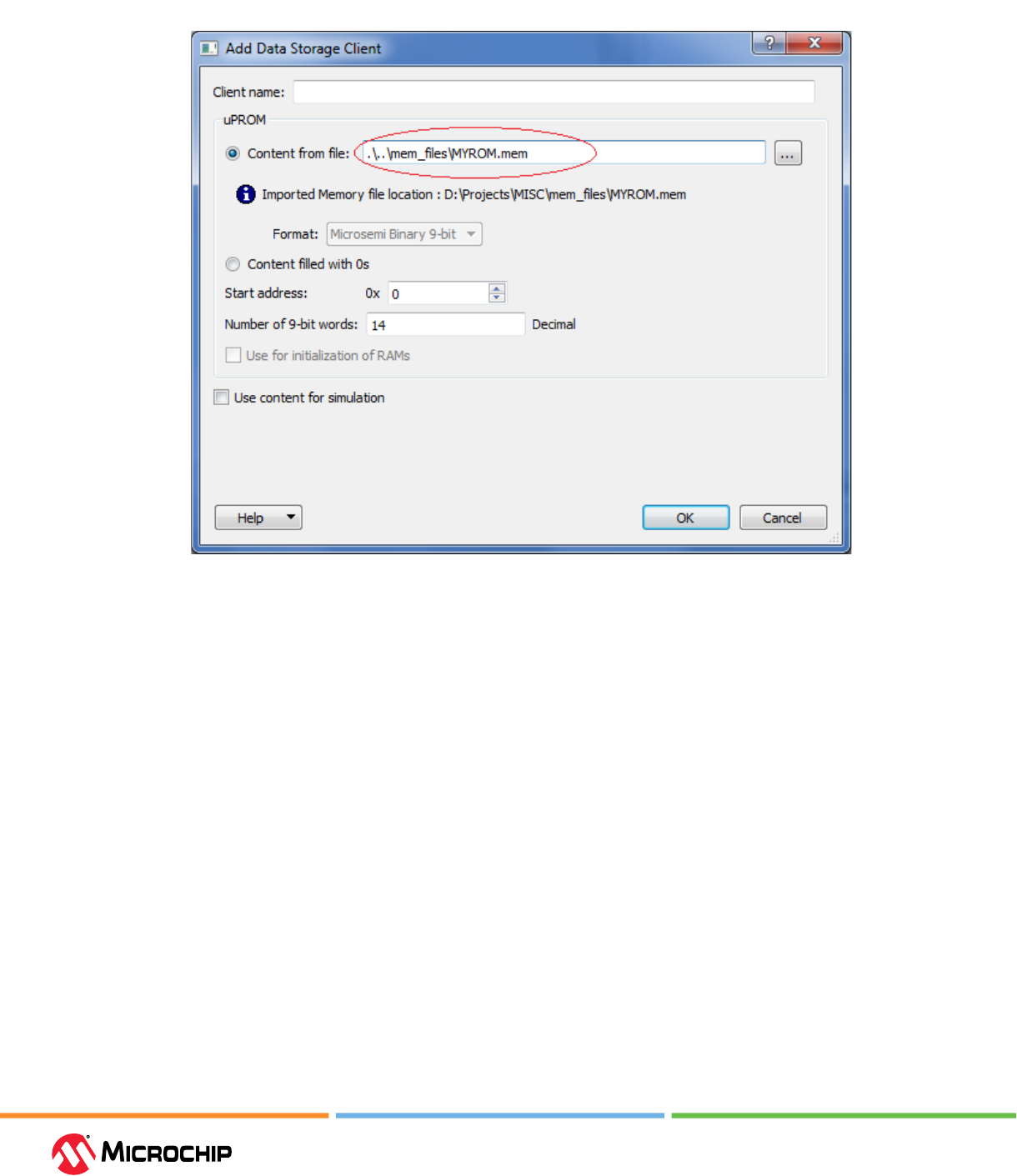

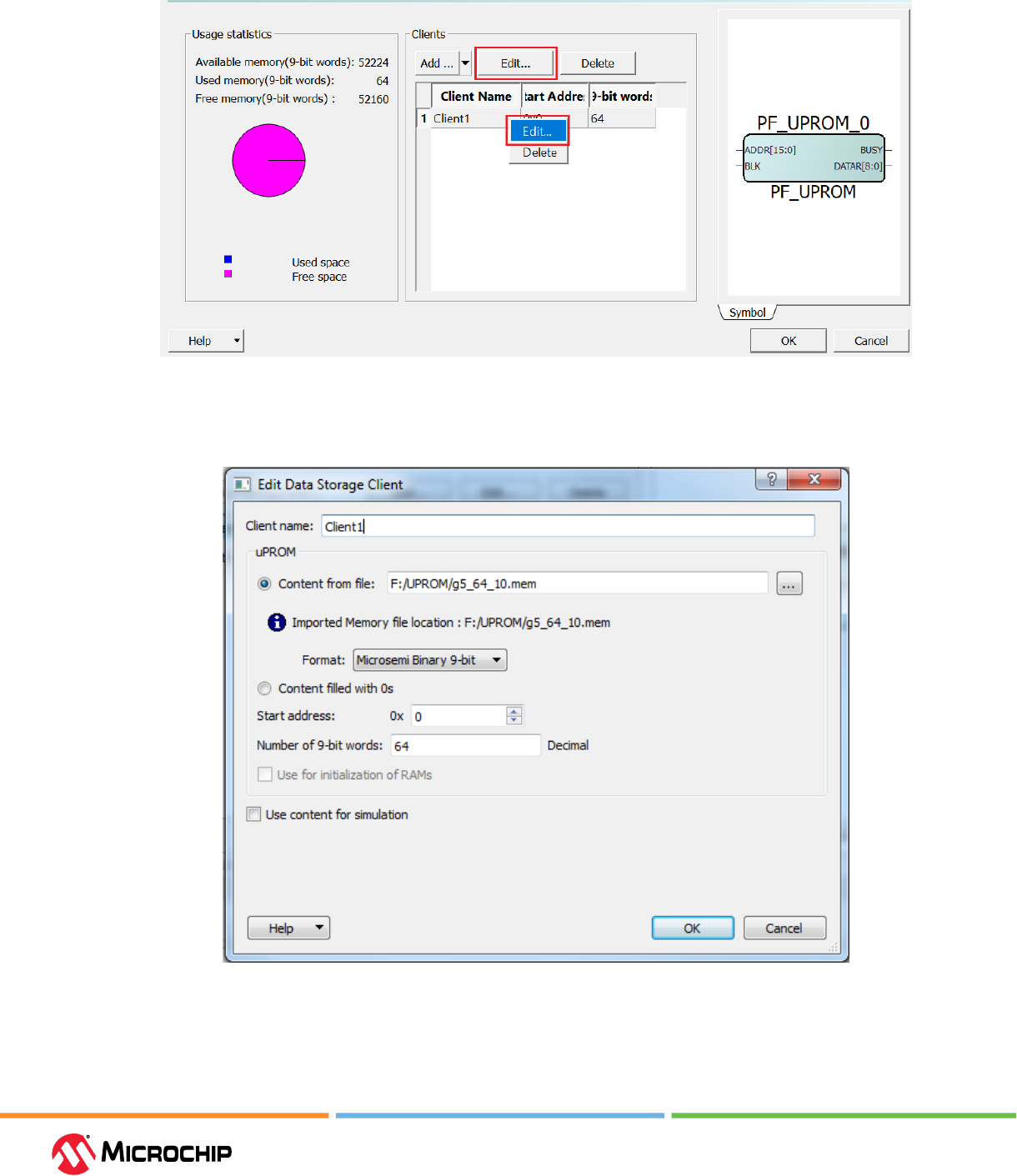

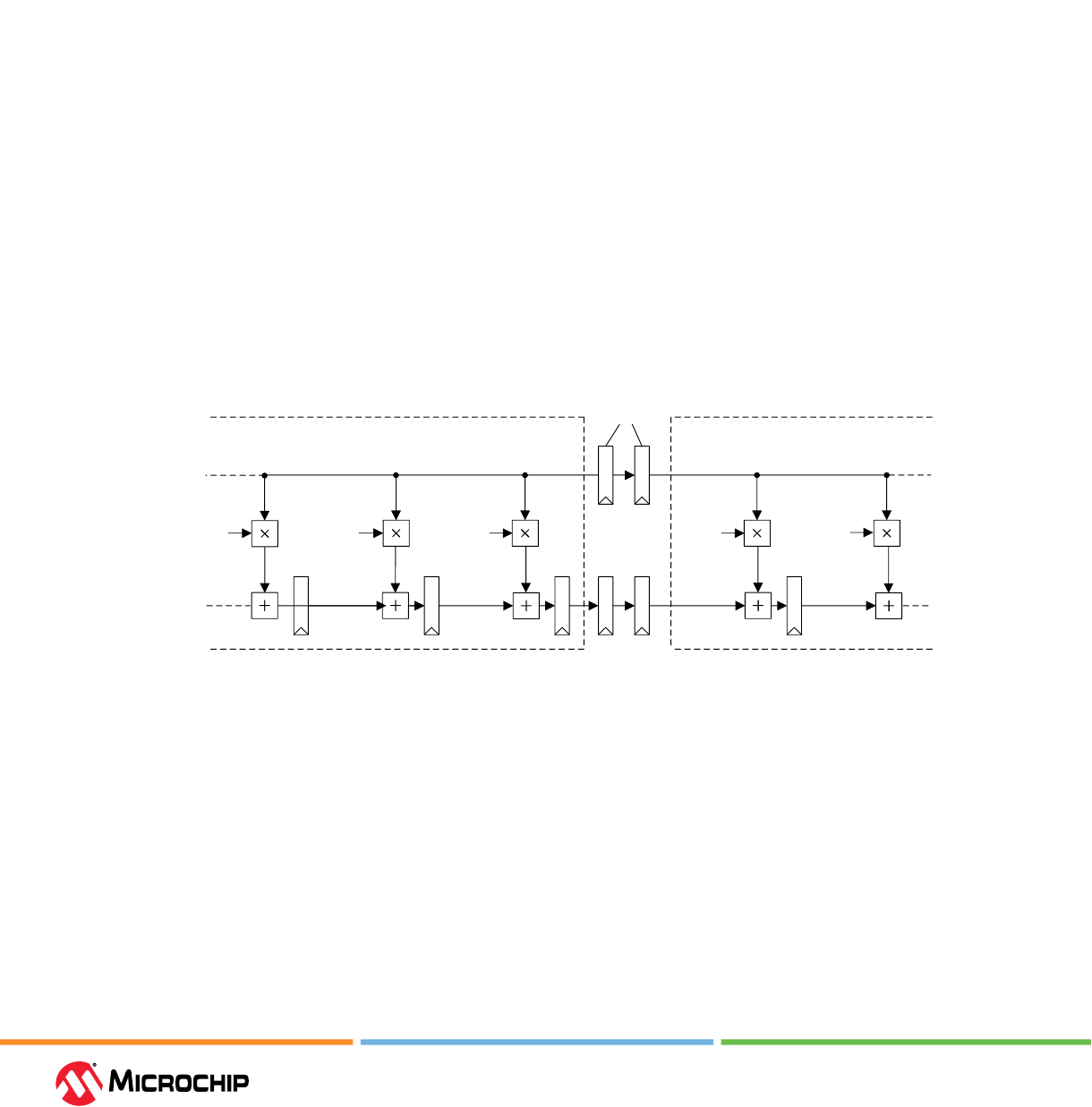

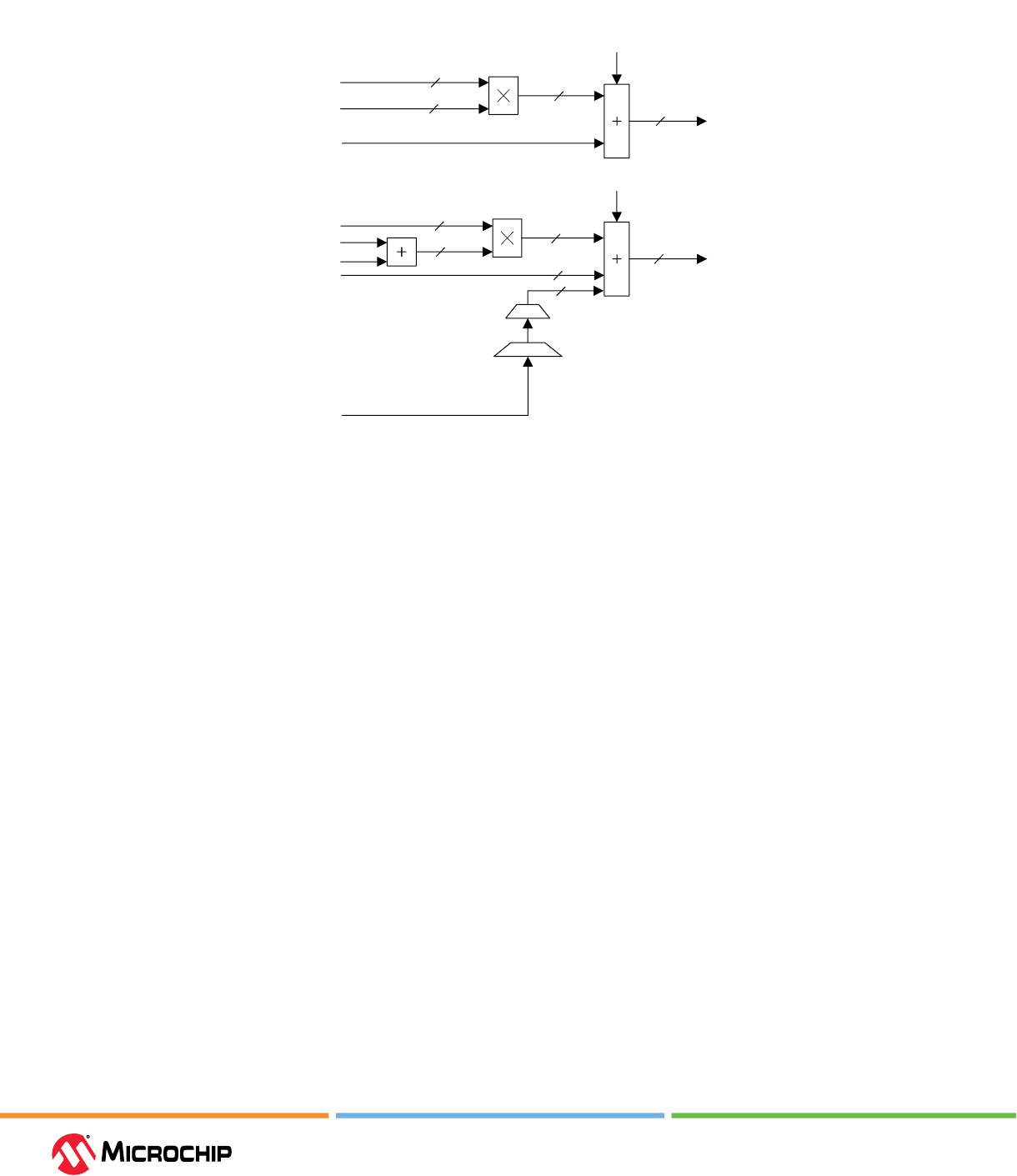

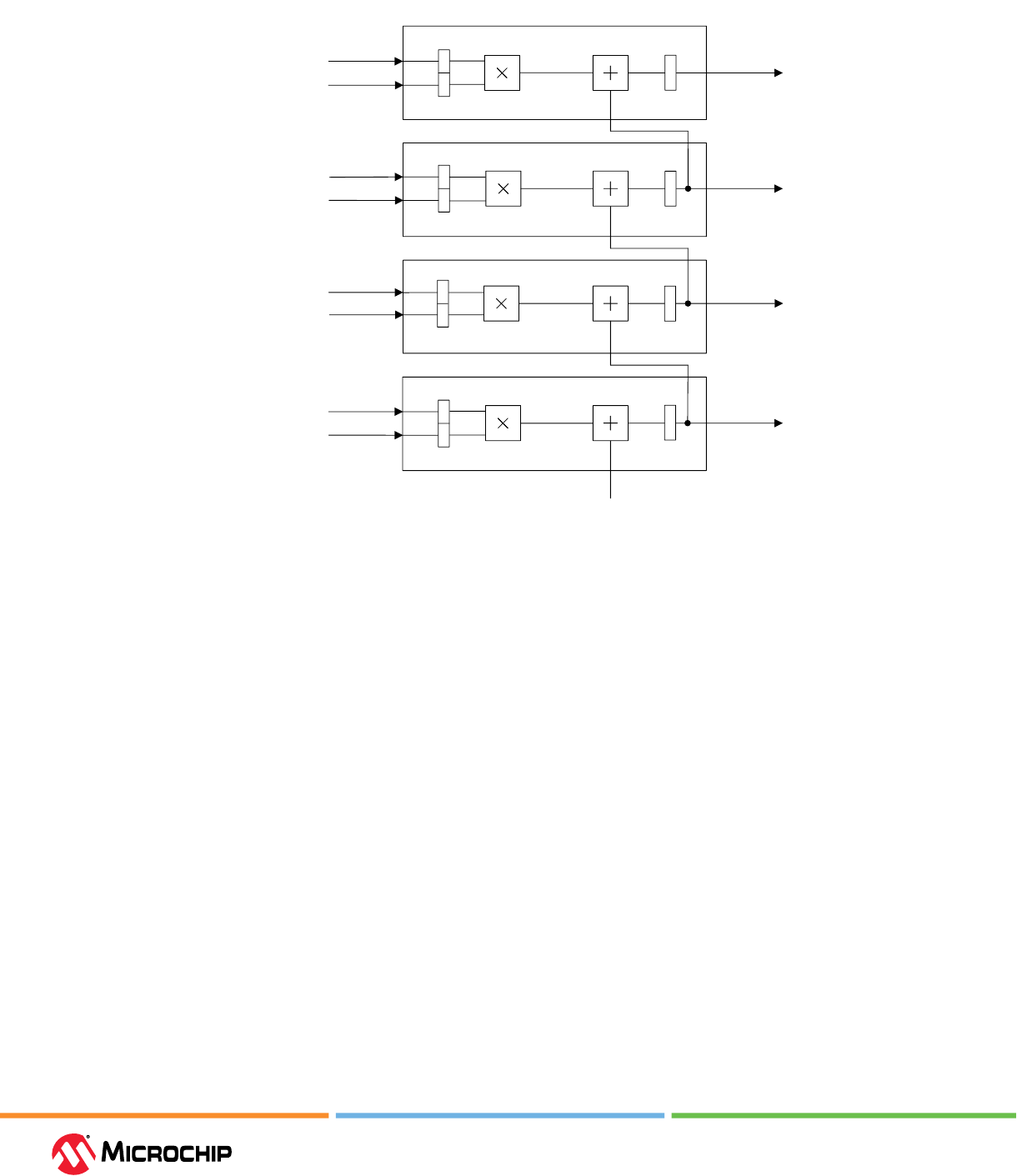

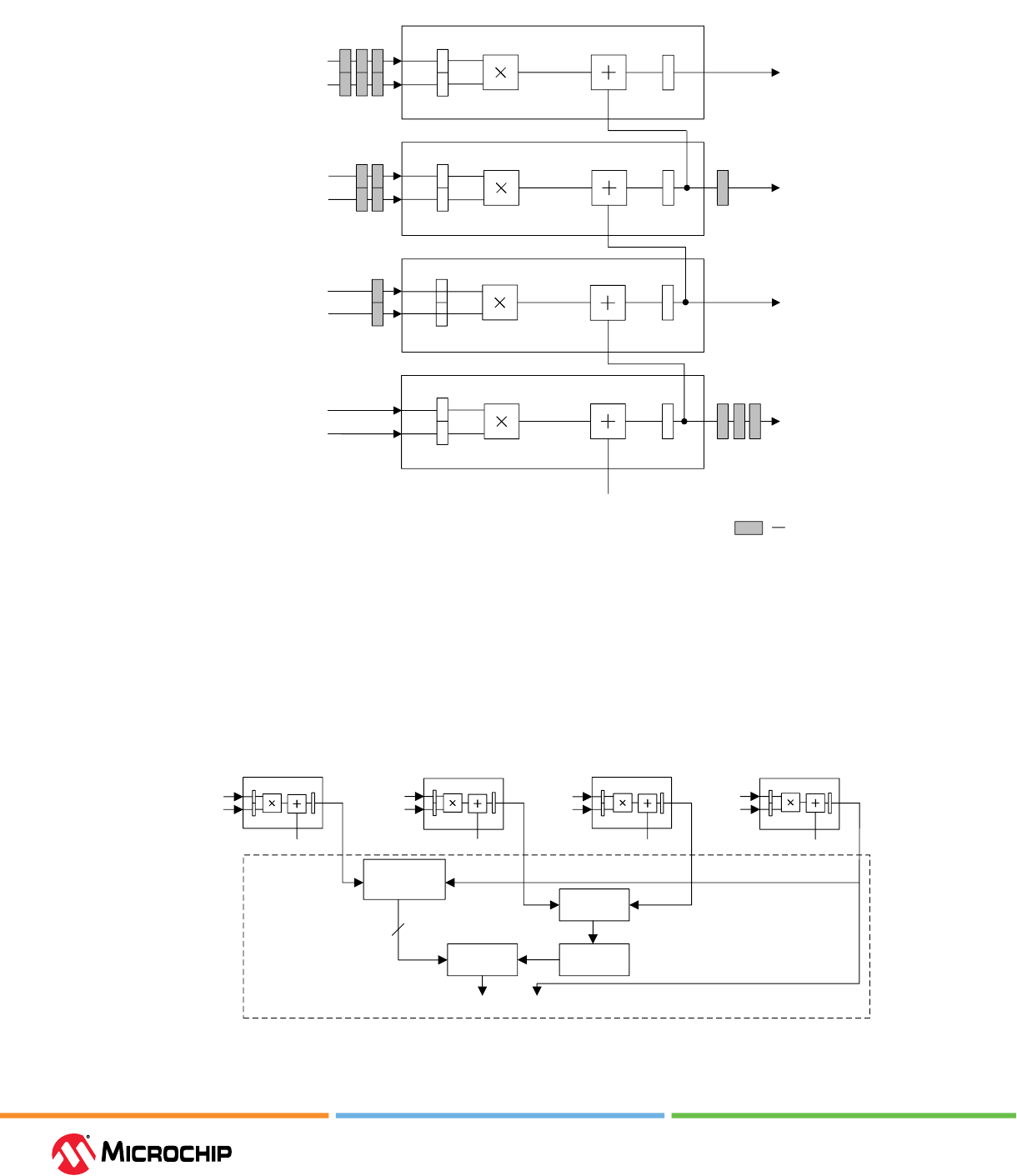

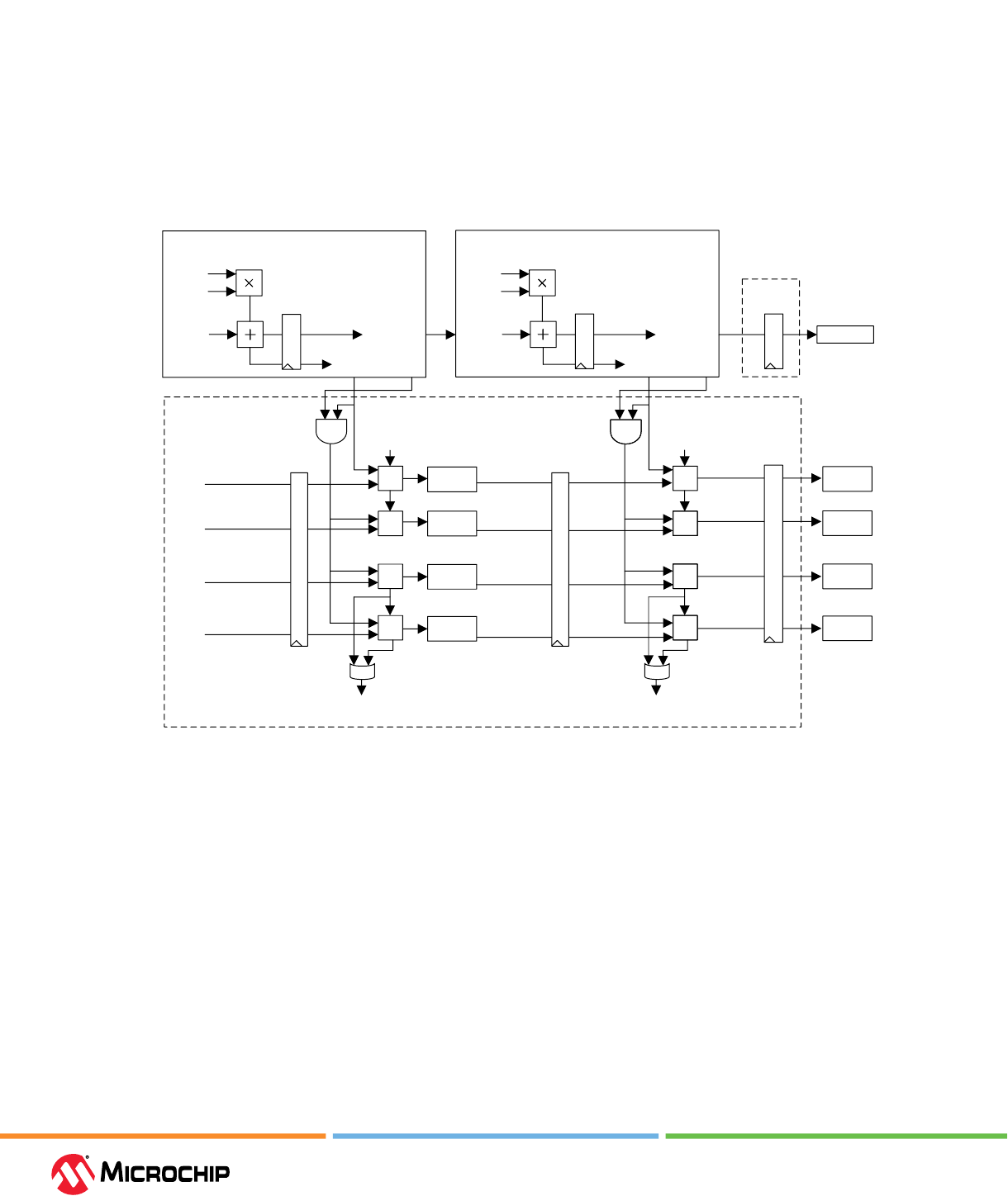

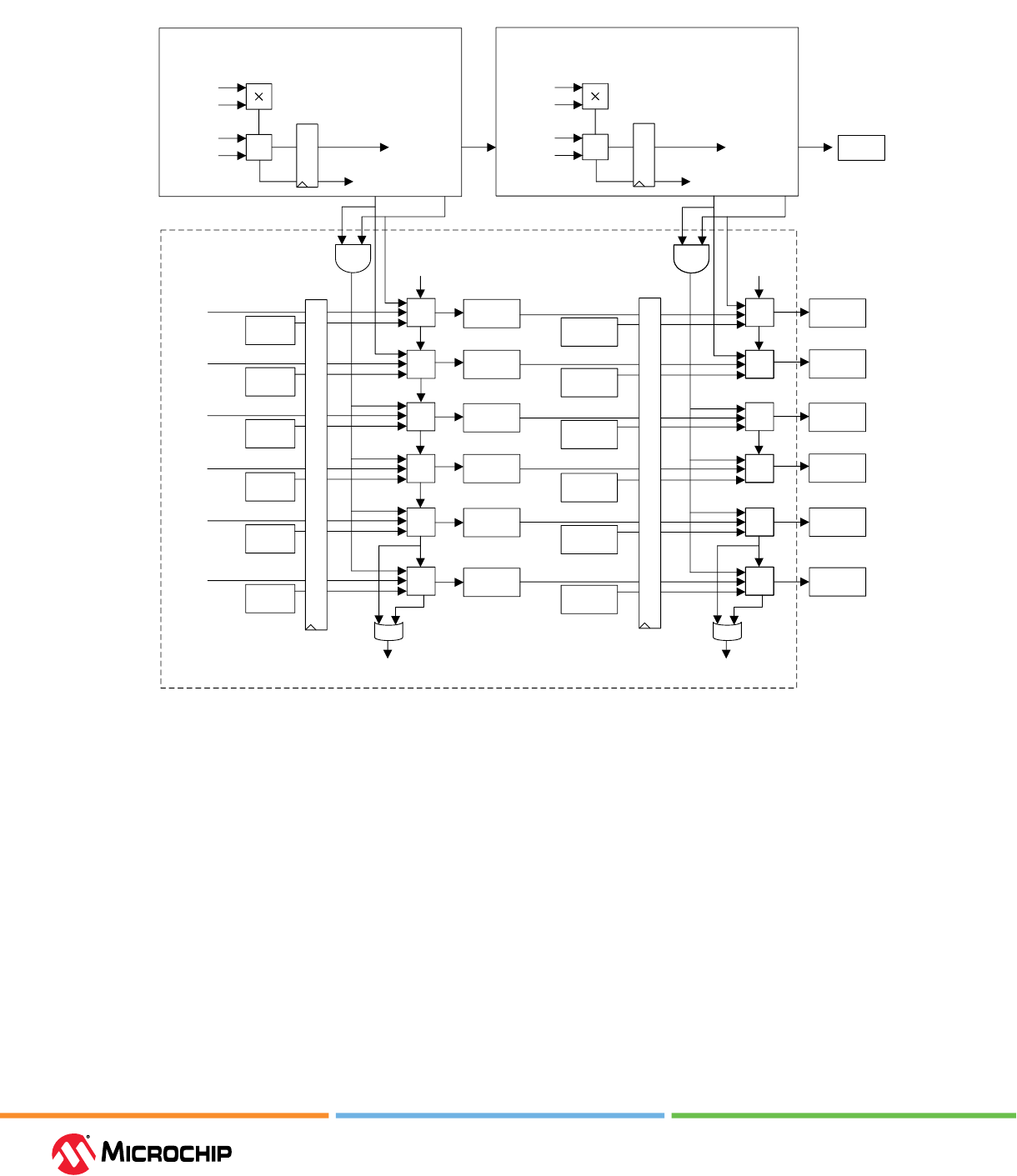

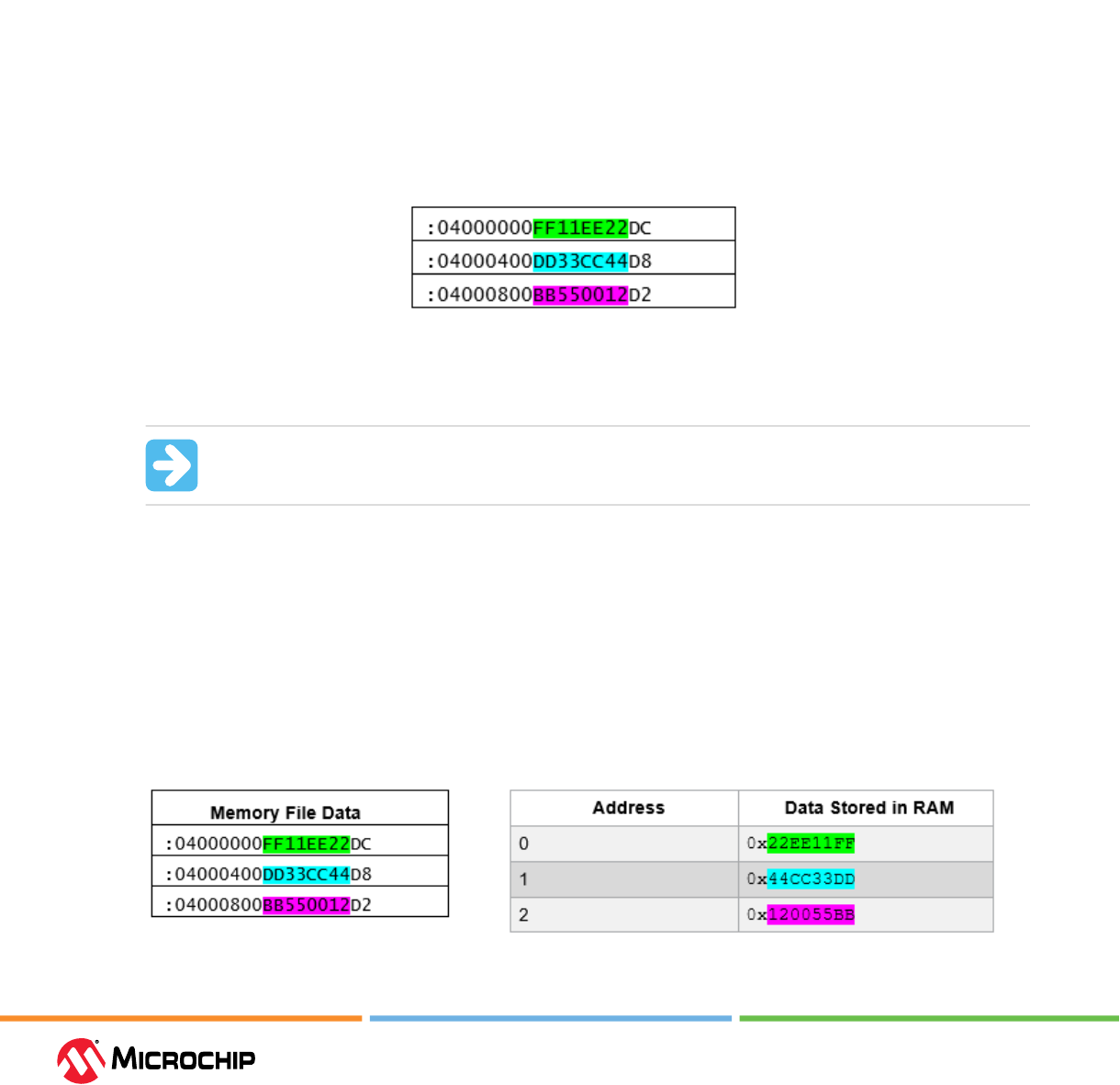

DS60001725G - 35